- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HAINZAR

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

22000*2500*2800mm

-

Power (kW):

-

105

-

Weight:

-

7500 KG

-

Motor brand:

-

Siemens beide

-

Inverter:

-

ABB

-

Contactor:

-

Schneider

-

Temperature control meter:

-

Ormon

-

Material:

-

PVC resin + CaCO3 + other

-

Cooling way:

-

Water cooling+Air cooling

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw Speed (rpm):

-

34.7 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HAINZAR

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

22000*2500*2800mm

-

Power (kW):

-

105

-

Weight:

-

7500 KG

-

Motor brand:

-

Siemens beide

-

Inverter:

-

ABB

-

Contactor:

-

Schneider

-

Temperature control meter:

-

Ormon

-

Material:

-

PVC resin + CaCO3 + other

-

Cooling way:

-

Water cooling+Air cooling

Products Description

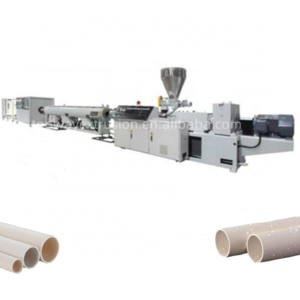

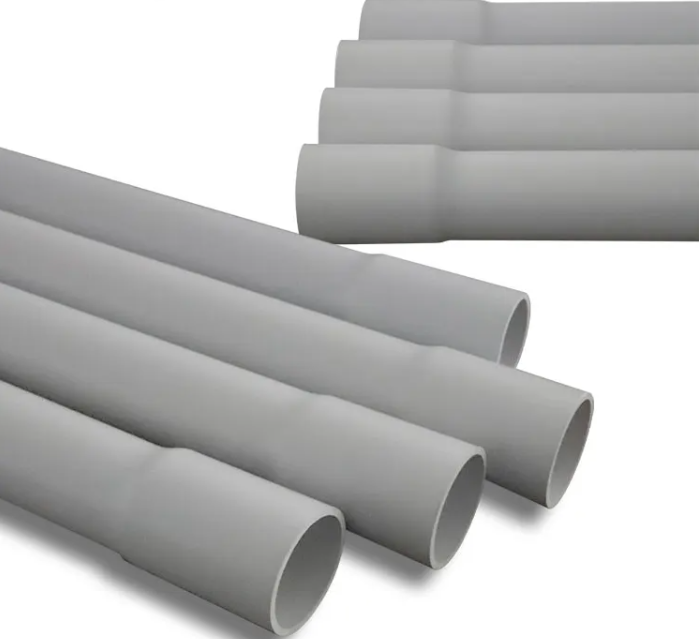

20-110mm Full Automatic UPVC CPVC PVC Plastic Electric Pipe Manufacturing Machine For Sale

Plastic pipe extrusion production line is used to produce PVC/UPVC/CPVC pipe with diameter from 16 up to 800mm, which is used for electric conduit, building drainage, sewage pipe, water supply pipe, well casing pipe, agricultural irrigation pipe and so on.

This equipment is mainly used for producing pipe diameter ranges: Φ 63mm- Φ 200mm.

The whole production line includes:

1. Plastic powder screw loader

2. SJSZ series conical twin screw extruder

3. Pipe extrusion mold

4. Vacuum calibration tank

5. Haul off machine

6. Cutting machine

7. Stacker / Belling machine

Other related machine:

8. High speed hot & cooling mixing machine

9. Air cooling chiller

10. Printer

11. Crushing machine

12. PVC pulverizing machine / PVC mill machine

Details Images

Specification

|

Pipe Diameter (mm)

|

Extruder Type

|

Extrusion Power (kw)

|

Max.Capacity (kg/h)

|

Max.Haul off Speed (m/min)

|

|

Φ16-40 Dual

|

51/105

|

18.5

|

120

|

10

|

|

Φ20-63 Dual

|

65/132

|

37

|

250

|

15

|

|

Φ20-63

|

51/105

|

18.5

|

120

|

15

|

|

Φ50-160

|

65/132

|

37

|

250

|

8

|

|

Φ63-200

|

65/132

|

37

|

250

|

3.5

|

|

Φ110-315

|

80/156

|

55

|

450

|

3

|

|

Φ315-630

|

92/188

|

110

|

800

|

1.2

|

|

Φ510-1000

|

130/26

|

160

|

1000

|

1.3

|

Auxiliary

Printer

Belling machine

Plastic powder screw loader

PVC pulverizing machine / PVC mill machine

High speed hot & cooling mixing machine

Crushing machine

Threading machine

Chiller

Air compressor

Packaging Shipping

About Hainzar

Zhangjiagang Hainzar Industrial Co.,LTD was founded in 2012 and is an advanced supplier of plastic machinery equipment and solutions. The company is located in Zhangjiagang City, Jiangsu Province, China.

We have 12000 square meters land and new modern workshop, we mainly development, design, manufacture and marketing plastic pelletizing machine, plastic recycling machine, PET bottle recycling machine, PVC pipe making machine, PE pipe making machine, PVC foam board production line, plastic granulator, plastic shredder, plastic pulverizer, plastic agglomerator, plastic crusher and so on.

Welcome inquiries from new and old customers.

Exhibition

FAQ

Are you a factory or a trading company?

HAINZAR is a high-end export brand of BEIRUI Group. We have our own factory, and many high-quality suppliers. We provide "all-in-one solution" for all series of plastic extrusion machinery. We provide you with superior quality and guaranteed satisfaction, you will never overpay again.

How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 45-60 days if the goods are not in stock, it is according to what kind of machine you need.

What payment options do you offer?

We are flexible in terms of payment. We can do LC, TT, DP, even credit, after auditing the customer.

Why choose us?

Low cost, all the machine, we make it ourself to reduce the cost of our customer, genuine product with excellent quality, we choose our material very strict. All the material come to our factory must pass the quality test.

How to install machine?

We will arrange our engineer to customer factory for installation and teach local workers to operation and maintenance, we also can send experienced master to work at customer's factory three month or more according to requirements.

Hot Searches