- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v - 510v

-

Dimension(L*W*H):

-

customized

-

Warranty:

-

one year

-

Certification:

-

CE ISO

-

Power:

-

40kw

-

Weight:

-

4500kg

-

floor area:

-

280 square meters

-

color:

-

customized

-

Part 1:

-

ring cutter

-

Part 2:

-

strips cutter

-

Part 3:

-

block cutter

-

Part 4:

-

bead sepatator

-

Part 5:

-

magnet sepatator

-

Part 6:

-

fiber sepatator

-

power:

-

380v

-

frequency:

-

50Hz

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suiteque

-

Model Number:

-

all various

-

Voltage:

-

220v - 510v

-

Dimension(L*W*H):

-

customized

-

Warranty:

-

one year

-

Certification:

-

CE ISO

-

Power:

-

40kw

-

Weight:

-

4500kg

-

floor area:

-

280 square meters

-

color:

-

customized

-

Part 1:

-

ring cutter

-

Part 2:

-

strips cutter

-

Part 3:

-

block cutter

-

Part 4:

-

bead sepatator

-

Part 5:

-

magnet sepatator

-

Part 6:

-

fiber sepatator

-

power:

-

380v

-

frequency:

-

50Hz

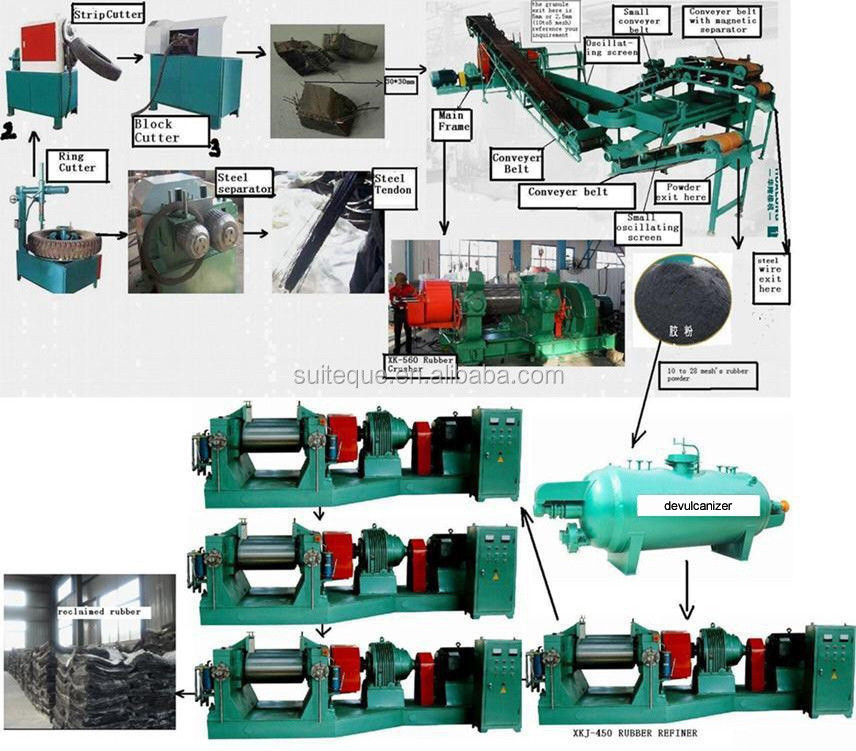

Waste Tyre Recycle Production Line / Tyre Recycling Plant

1. GENERAL:

The complete production line is mainly used for recycling scraptire (steel tyre and textile tyre),

the final product is rubber powder or reclaimed rubber.

2.Process flow:

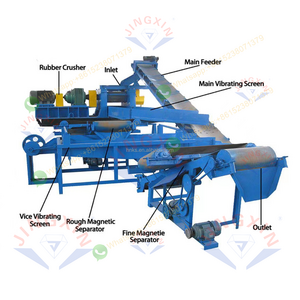

waste tyre-ring cutter →strips cutter → blocks cutter → rubber crusher→ vibrating screen1→big magnetic separator→

small shaking screen - small magnetic separator - rubber powder - dynamic devulcanizer - open mixing mill(1)

- open mixing mill(2/3) - rubber refiner.

The whole line has the following features:

1), iron/steel removing ratio>99.5%, fiber removing ratio>98%

2),compact structure ensure running safety, easy maintenance;

3),low energy consumption;

4),adopt automatic control system for whole line, reduce labor cost;

5),no sewage and waste gas discharge, environment protection.

6), available capacity range of our tire recycling lines at present: 400~3000kg/h

7), available finial rubber powder size: 30~120mesh.

8), adopts SIEMENS and Chinese famous brand electrical elements.

3.This production line including the below:

|

No |

Name |

Model

|

Number |

|

1 |

Ring cutter |

QQJ-20 |

1 |

|

2 |

Strip cutter |

QTJ-380 |

1 |

|

3 |

Block cutter |

QKJ-45 |

1 |

|

4 |

Loop machine |

YQJ-285 |

1 |

|

5 |

Conveyor equipment |

BSJ-1100, XSJ-600 |

2 |

|

*6 |

Rubber crusher |

XKP400/XKP450/XKP560 |

1 |

|

7 |

Magnet separator |

BCX-2, XCX-1 |

2 |

|

8 |

vibrating screen |

BS-8, XS-4 |

2 |

|

*9 |

Fiber separator |

XFJ-1100 |

1 |

|

10 |

Rubber grinder |

XMF-270/330/420 |

1 |

*6: there is 3 types of rubber crusher, you can choose the suitable one ,it depends on the output!

*9 :you have no need Granulator Grinder if your final rubber powder bigger than 30 mesh.

but you need it if the powder less than 30 mesh and the numbers of this machine depend on the output!

4. Analysis for output :

1).XKP400 rubber crusher:

Output: 4500-6000kg/24 hour for about 20 mesh granule.

2).XKP450 rubber crusher:

Output :7000-12000kg/24 hour for about 20 mesh granule.

3).XKP560 rubber crusher:

Output : 10000-17000kg/24 hour for about 20 mesh granule.

Designing and compounding special specification products according to the customers' requirements

Packing

Our Services

We can provide better service to you:

1.Adopting reasonable packaging suit for long ocean transport.

2.Can offer the raw material constantly according to the buyer’s requirements.

3.Train you how to operate the machine.

4.Provide overseas maintenance and plant design.

5.Offer technical support.