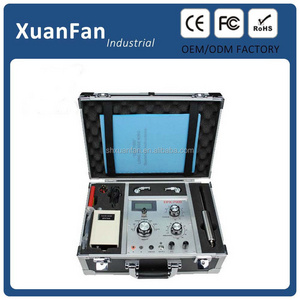

INSTRUMENT CHARACTERISTICS :

1. Granite base and column, with strong rigidity, small deformation, high accuracy, and good stability.

2. Precision toothless screw drive design, achieving fast movement and no rebound.

3. The three-axis adopts a combination of precision cross roller guide and linear guide to ensure machine accuracy and service life.

4. Manual zoom lens with card position, measurement can be done without calibration after magnification adjustment

5. High definition digital industrial camera, achieving high-definition and precise measurement of products.

6. DXF files can be imported and exported, and drawings can be compared with physical inspection results.

7. Measurement data can be quickly exported to Word, Excel, AutoCAD, and can be quickly photographed.

Selling points: SELLING POINTS :

Can achieve one click automatic detection.

Support customization, upgrade and add probes to measure 3D stereo features, and use probes of different shapes to achieve multi-directional detection.

The visual and probe structure functions complement each other's advantages and disadvantages. The probe compensates for three-dimensional features that cannot be detected by vision. Vision can detect small holes and thin parts that cannot be detected by the probe, improving the slow speed of point extraction when detecting the contour of open and closed curves.

FEATURES :

Low cost, high precision, high efficiency, and easy operation

FUNCTION :

With multiple functions such as one click automatic detection, automatic capture, automatic boundary judgment, intelligent filtering, and automatic export of detection results, it is suitable for measuring various batches, types, and complex shapes of products.

PROBE SIZE DETECTION CONTENT :

After upgrading and adding probes, 3D three-dimensional features can be measured, and with probes of different shapes,

multi-directional detection can be achieved. It is mainly used for detecting parts with thickness and inner space greater than 5mm.

1. Coordinate detection of points

2. Length, straightness, parallelism, inclination, and perpendicularity detection of lines.

3. Detection of diameter, radius, roundness, and center coordinates of circles and arcs

4. Size and angle detection of rectangles and polygons

5. Ring concentricity detection 6. Contour detection of open and closed curves

6. Surface flatness, surface to line (including axis, centerline, etc.), surface to surface distance, parallelism, verticality,

inclination, and symmetry detection

7. Diameter and cylindricity of cylinders, coaxiality between cylinders and circular holes

VISUAL SIZE DETECTION CONTENT :

When the product is horizontally placed, the dimensions of the elements on the upper surface are detected using 2D planar features, which are often used for detecting parts with thinner thickness.

1. Coordinate detection of points

2. Detection of line length, straightness, parallelism, inclination, and verticality

3. Diameter, radius, roundness of circles and arcs, and coordinate detection of the center of the circle

4. Size and angle detection of rectangles and polygons

5. Ring concentricity detection

6. Contour detection of open and closed curves.

APPLICATION SCENARIOS :

Machinery, electronics, motors, mobile phones, cutting tools, hardware, fasteners, bearings, gears, molds, stamping parts,

injection molding, rubber, low-voltage electrical appliances, connectors, terminals, automotive parts, power batteries, railway transportation, ships, aerospace, nuclear industry, medical equipment, instruments and meters, etc.