- Product Details

- {{item.text}}

Quick Details

-

Power:

-

45+18.5kw

-

Weight:

-

5400

-

Dimension(L*W*H):

-

4924*1170*1539mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Drum Dia(mm):

-

530

-

Drum Length(mm):

-

2280

-

Length-Diameter Ratio:

-

1:4

-

Rotation Speed(r/min):

-

2700

-

Power of motor(Kw):

-

45+15

-

Noise(DB):

-

≤80

-

Centrifuge:

-

Decanter centrifuge

-

Specification:

-

Flow Ethanol Separator Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Toper

-

Voltage:

-

380V

-

Power:

-

45+18.5kw

-

Weight:

-

5400

-

Dimension(L*W*H):

-

4924*1170*1539mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Drum Dia(mm):

-

530

-

Drum Length(mm):

-

2280

-

Length-Diameter Ratio:

-

1:4

-

Rotation Speed(r/min):

-

2700

-

Power of motor(Kw):

-

45+15

-

Noise(DB):

-

≤80

-

Centrifuge:

-

Decanter centrifuge

-

Specification:

-

Flow Ethanol Separator Machine

Flow Ethanol Separator Machine Continuous Decanter Centrifuge Industrial Price

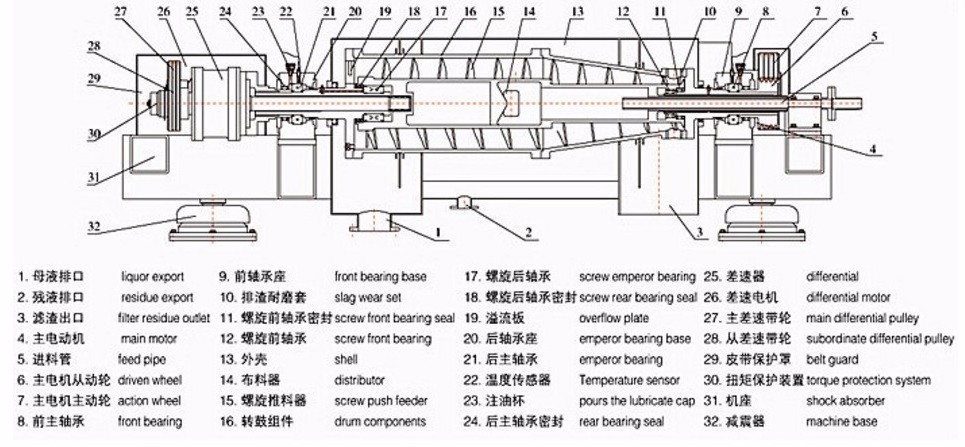

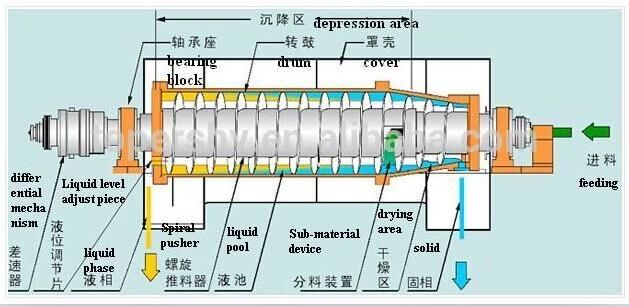

The Horizontal Decanter Centrifuges are a kind of horizontal solid-bowl scroll discharge sedimenting centrifuge. They can be continuously operated and can perform feeding, separating, washing and discharging in sequence at their full-speed running. Their advantages are: compact structure, continuous operation, stable performance, fine adaptability, large capacity and easy maintenance. They are suitable for separating the materials with their solid density larger than their liquid density, that is, the suspension with solid phase particle size of more than 0.005mm and with the concentration of 2-40%. They are suitable for chemical industry industry, light industry, pharmacy and food industry as well as environment protection Meanwhile, we can offer tailor-made centrifuge for the customer’s special requirements and offer the test on the spot. Of course, you are also welcomed to our institute. In the past few years, by cooperating with foreign company, we have developed decanter whose length- diameter ratio is bigger than 4.Due to increasing the length of the sedimentation zone and staying time, so separating efficiency is very obvious-(These productions have been exported to America, Germany, France and other countries for some years)With the help of our experience in solid bowl decanter centrifuge, we have developed the Mobile Sludge Dewatering Unit and Whole Sludge Dewatering Unit, which fill up vacancy in this field for the first time in China.

Strcture and Working Principle:

Process advantages of Horizontal Decanter Centrifuge

Process flexibility

Constant separation results, even at fluctuations in the volumetric flow, the process conditions, or the product characteristics

Process condi tions

1)gas-tight, vapor-tight, or pressurized operation

2)low vibration levels

3)absolute pressures from 0 to 8 bar

4)-90° C to +200° C

5)CIP cleaning

6)flameproof or explosion-proof standards making the decanter ideal for applications with solvents and hazardous materials

Cemical resistance

Materials such as titanium, pure nickel, or Hastelloy provide the security essential in demanding process applications.

Low space requirement

1)compact design at high specific throughput

2)self-contained system, therefore no extra space required for peripheral equipment

Low operating costs

Operating consumables (e.g. filter cloths) are not required. No costly downtime for changing consumables.

Simple installation

1)integration of all necessary functions in one package (e.g. no need for peripheral equipment)

2)active support system (no foundations)

Operation

1. Clarification: Clarification is the separation of solids from a liquid of lower density over a particle size range from 1 to 10,000 microns. By increasing the centrifugal force, it is possible to also separate very small particles in the submicron range, even with very small differential density.

2. Classifying: By controlled reduction of the residence time, classification according to particle size, down to the submicron range, can be achieved with sharp separation cuts.

Liquid/liquid separation

Liquid phases of differing densities can also be separated.

3. Thickening : Fine solids separated from the liquid can be thickened in a hindered settling mode, utilizing the volume of the cylindrical section of the decanter to maximize compression.

4. Compression: Compactive dewatering provides a substantially higher degree of dewatering with compressible solids.

5. Washing: Efficient and cost-effective counter-current washing is made possible by separate removal of the wash liquor over several sections of the screen.

6. Dewatering: The solids dewater by a combination of drainage and compression. The degree of drainage/compression depends on the nature of the solids, the setting of the centrifuge, and the required degree of dewatering. The transport and discharge of pasty, sludge-like or shear-sensitive solids are facilitated by the appropriate combination of conveyor geometry, cone geometry, and control of the differential speed.

7. Mixing and re-suspension: Special solids discharge geometry (gutter) allows the dewatered solids to be mixed with liquid directly at the discharge, thus eliminating the need for an additional mixing vessel.

Major applications

1)Organic chemicals

2)Inorganic chemicals

3)Ores and minerals

4)Water and wastewater

5)Food and pharmaceuticals

Main technical parameters:

|

Models |

Drum Dia(mm) |

Drum Length(mm) |

Length-Diameter Ratio |

Rotation Speed(r/min) |

Relative Centrifugal force |

Power of motor(Kw) |

Noise(DB) |

|

LW355*1600 |

355 |

1600 |

1:4.5 |

3800 |

2868 |

15+7.5 |

≤80 |

|

LW400*1200 |

400 |

1200 |

1:3 |

3400 |

2587 |

18.5 |

≤80 |

|

LW400*1800 |

400 |

1800 |

1:4.5 |

3400 |

2587 |

22+7.5 |

≤80 |

|

LW450*1350 |

450 |

1350 |

1:3 |

3450 |

3000 |

30+11 |

≤80 |

|

LW450*1800 |

450 |

1800 |

1:4 |

3450 |

3000 |

30+11 |

≤80 |

|

LW450*2000 |

450 |

2000 |

1:4.5 |

3400 |

3000 |

30+11 |

≤80 |

|

LW530*2280 |

530 |

2280 |

1:4 |

2700 |

2150 |

45+15 |

≤80 |

More photos:

Application of horizontal decanter centrifuge:

FAQ:

Q1.What’s your advantage? Why we choose you?

A:1)10 Years experience of filter press production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use 100% new materials and the best production process

Q2.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.For large

quantity,sea shipping can be provided.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4: How long is the warranty period?

12 months.