- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

2.3x2.0x2.3m

-

Weight:

-

2300 KG

-

Local Service Location:

-

None

-

After sales Service Provided:

-

Video technical support

-

After-sales Service Provided:

-

Online support

-

Recovery rate:

-

95-98%

-

Installation:

-

Engineer Guide

-

Capacity:

-

3-100 Tons / Hour

-

After sale service:

-

Engineer Overseas Service

-

Feeding size:

-

0-6mm

-

Certification:

-

ISO9001

-

Concentration ratio:

-

1000 times

Quick Details

-

Production Capacity:

-

95% Recovery Rate

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXWKD

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

2.3x2.0x2.3m

-

Weight:

-

2300 KG

-

Local Service Location:

-

None

-

After sales Service Provided:

-

Video technical support

-

After-sales Service Provided:

-

Online support

-

Recovery rate:

-

95-98%

-

Installation:

-

Engineer Guide

-

Capacity:

-

3-100 Tons / Hour

-

After sale service:

-

Engineer Overseas Service

-

Feeding size:

-

0-6mm

-

Certification:

-

ISO9001

-

Concentration ratio:

-

1000 times

Product Overview

Centifugal Concentrator

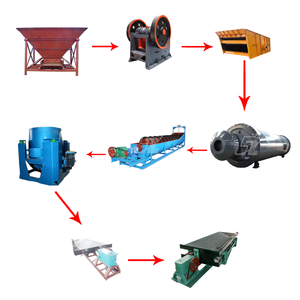

Gold centrifugal concentrator also called knelson concentrator is a new type of gravity concentration equipment, used in the gold mining industry. It is used for the recovery of fine particles of free gold, meaning gold that does not require gold cyanidation for recovery.

Working Principle

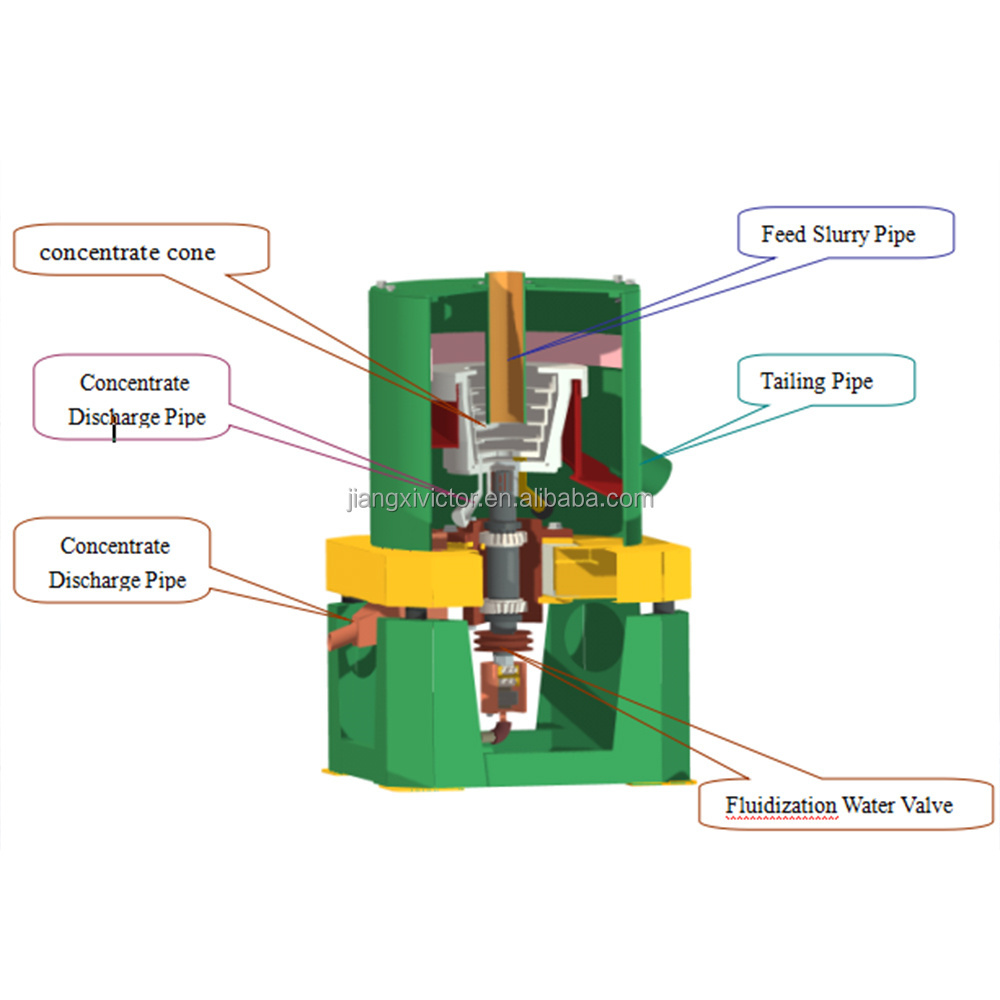

The hollow shaft of gold centrifugal concentrator can be driven by electrical motor transmission part through belt driving, making the rotation inner sleeve rotate in a high speed to produce centrifugal force. The slurry will be fed into the rotation inner sleeve through feeding pipe, and the slurry particle will be separated under the action of centrifugal force field. The heavy mineral will be remained in the cell guide of rotation inner sleeve, and the light mineral will be discharged through the tailings launder. After one shift work and stop running, the concentrate will be discharged through the concentrate discharge outlet.

Structure

PRODUCT SPECIFICATIONS

|

Technical Parameters

|

|

|

|

|

|

|||||

|

Model

|

STLB20

|

STLB30

|

STLB60

|

STLB80

|

STLB100

|

|||||

|

Capacity(t/h)

|

0-0.6

|

2-3

|

8-12

|

40-45

|

80-120

|

|||||

|

Fluidization Water Required(m³/h)

|

2-3

|

3-5

|

7-10

|

30-36

|

60-80

|

|||||

|

Slurry Water Required(m³/h)

|

1.5-4

|

5-7

|

8-12

|

40-45

|

70-100

|

|||||

|

Feeding Density(%)

|

0-50

|

0-50

|

0-50

|

0-50

|

0-50

|

|||||

|

Feeding Size(mm)

|

0-3

|

0-3

|

0-5

|

0-5

|

0-5

|

|||||

|

Concentrate cleaning Up Cycle

|

Vein Gold:1-3 Hours;Placer Gold:2-6 Hours

|

|

|

|

|

|||||

|

Concentrate Weight(Kg)

|

2

|

3-5

|

10-20

|

40-50

|

70-85

|

|||||

|

Power(Kw)

|

0.75

|

1.5

|

4

|

11

|

18.5

|

|||||

|

Weight(Kg)

|

205

|

380

|

1100

|

2300

|

3200

|

|||||

|

Dimensions(mm)

|

914*700*900

|

1160*885*1165

|

1820*1450*1700

|

2476*2032*2018

|

2849*2085*2426

|

|||||

Details Images

Packing and Delivery

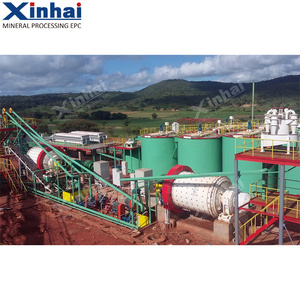

Successful Project

SIMILAR PRODUCTS

Hot Searches