- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

200

-

Dimension(L*W*H):

-

12*1.2*2.5m

-

Voltage:

-

380V

-

Power:

-

44.5KW, 44.5KW

-

Weight (KG):

-

2000

-

Production Capacity:

-

500-900kg

-

Product name:

-

Continuous carbonization furnace

-

Applicable raw materials:

-

Bamboo, coconut shell, palm shell, olive residue, wood chips, etc.

-

Raw material size:

-

less than 10cm

-

Moisture of material:

-

less than 25%

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Carbonization time:

-

Continously Working

-

Color:

-

Customer's Request

-

Cooling time:

-

Immediately

Quick Details

-

Place of Origin:

-

Henan,China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

ZHUOZHILAN MACHINERY

-

Effective Volume:

-

200

-

Dimension(L*W*H):

-

12*1.2*2.5m

-

Voltage:

-

380V

-

Power:

-

44.5KW, 44.5KW

-

Weight (KG):

-

2000

-

Production Capacity:

-

500-900kg

-

Product name:

-

Continuous carbonization furnace

-

Applicable raw materials:

-

Bamboo, coconut shell, palm shell, olive residue, wood chips, etc.

-

Raw material size:

-

less than 10cm

-

Moisture of material:

-

less than 25%

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Carbonization time:

-

Continously Working

-

Color:

-

Customer's Request

-

Cooling time:

-

Immediately

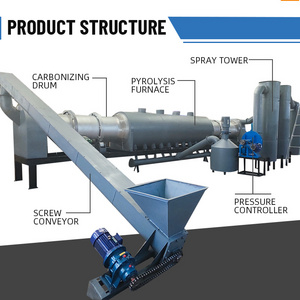

Product Description

1.Continuous carbonization furnace charcoal making machine is a special carbonization equipment for dry distillation and oxygen-free carbonization of small carbon-containing wood materials such as shell sunflower seed shells under high temperature conditions in the carbonization machine.

2.It can carbonize different materials into charcoal, such as sawdust, wood chips, rice husk, sugarcane bagasse,etc. Finished charcoal can be sold in the market directly, or deep processing into bbq charoal, shisha charcoal, etc. The whole set mainly contains carbonization furnace, gasification furnace, charging part, discharging part, fan, etc.

3.Continuous carbonization furnace charcoal making machine adopt superior purifying technology, and is made from special high temperature resistant material, and show the features of stable and wear well, superior insulating property, easy operation, safety and reliable, finished products ratio more than 95%, labour and time saving, energy-saving, environmental-protection and high efficient, and one person can operate several carbonization stove simultaneously.

Working Principle

Equipped with:

Gasfication furnace, flue gas purifier, flue gas condenser, fan, self-mixing burner, horizontal carbonization furnace and other equipment.

Main machine include:

Input screw, output screw, cooling conveyor, coal gas or natural gas generater, rotary drum, smoke removal device, control cabinet, gas cleaning and recycling system.

Recycling of advanced technology:

That is to solve the problem of environmrntal pollution caused by the ordinary carbonization furnace produced in the carbonization process of smoke and solve the problem of heat required equipment. It is more efficient and economic.

Carbonization Process

A-Drying stage: temperature 160-200 ℃ in the process of evaporation of water in the raw materials.The wood chips are fully in contact with hot air and then discharged from the output air locker for machine carbonizatio.

B-Initial carbonization stage: temperature is 200-400℃, the raw materials are self-igniting, and thermal decomposition reaction occurs. In this process, there will be CO₂, CO and wood acetic acid production.

C-Overall carbonization stage: temperature is 400-800℃, the material is fully carbonized, in the process there are CH₄, C₂H₂ and other combustible gases, providing flammable gas for the initial carbonization stage.

D-Cooling stage: temperature 260-280℃.

Manufacturing Technique

(1) Outer stove

Include heating room (for heating the inner stove), furnace body and heat-keeping layer (it is made of the heat insulating material)The material completes the carbonization reaction of this equipment.Main Roller Made of Q235, 245R 310s Stainless Steel.

(2) Inner stove

Consist of the stove tank body and the sealed top cap. Both of them are made of the heat resistance thermal steel, three inner stove can be stacked together for saving space and shipping cost.

(3) Smoking recycle tube

uring the process of carbonizing, there will be some smoke.( can be burning) the smoke can be collected and returned to the furnace.

(4)System condenser

The gas treated in the flue gas condenser is cooled for 2 times and is pure.

(5) Purification tank

This system is consisting of purification tank and the exhaust-heated cycle pipe. Smoke scruber-cleans hot smoke before releasing water meeting emission standards.Using advanced dust removal technology, dust removal and desulphurization.

(6) LPG/Natural Gas Burner

It is only for fire starting. The raw material will produce syngas for their own carbonization all the time.

(7) Gasifier Burner

It is only for fire starting.

The raw material will produce syngas for their own carbonization all the time.

(8) Diesel Burner

It is only for fire starting.

The raw material will produce syngas for their own carbonization all the time.

Features & Advantages

The equipment is safe and environmentally friendly, with stable operation and long service life.

1.Central control can be designed according to the customer’s request, which can separate the operator and machine.

2.A large number of new materials and new processes are selected, patented technology design, precision production, and after a lot of practical tests, every detail is pursued for perfection to ensure the quality of each set of equipment.

3.Power supply section has a standardized control system, Configured with sealing system, iginition alarm equipment system to ensure the environmental cleanliness and production safety.

|

Type

|

Motor (kw)

|

Capacity (kg/h)

|

Host Size(W*H*L)

|

Host Size(W*H*L)

|

|

CJL800

|

11

|

400-500

|

1000*1700*8000mm

|

900degree

|

|

CJL1000

|

12

|

600-800

|

1000*1700*8000mm

|

|

|

CJL1200

|

18.5

|

800-1000

|

1500*2000*8500mm

|

|

Applicable Materials & Application

The material has strong adaptability:

Biomass with moisture less than 20% and particle size less than 30mm can be carbonized. This machine is suitable for all kinds of agricultural and forestry biomass charring making. For example: wood shavings, sawdust, wood chip, rice husk, cotton stalk, crop straw, bean Stalks, straw, corn straw, soybean straw, sorghum straw, rape straw, peanut, sunflower stalk, grass and shrub branches, bamboo truncated, sprue, bagasse, coconut shell, walnut shell, apricot shell, hemp, bamboo, eucalyptus, fungus residue, medicinal residue, furfural residue, coffee grounds, palm shell, Sawdust, Cotton Stalk, Coffee Husk, Peanut Shells, Pine Needle, Rice Husk, Sugar Mill Waste, Jute Waste, Coir Pith, Smoke Stem, Bark, Eucalyptus Charcoal, Furfural Residue, Plants Stems, Palm Shell, Corncob, Fatlute, Wood Chips, Coffee Grounds, Chinese Medicine Residue, Wood Offcut, Chicken Manure.

|

End Products

|

Area

|

Usages

|

|

Charcoal

|

Daily life

|

• widely used as the fuel of BBQ.

|

|

|

|

• used as the fuel in other industries.

|

|

|

Agriculture

|

• attach heavy metal to improve the quality of the soil.

|

|

|

Industry

|

• can be reprocessed into activated carbon.

|

|

|

|

• used for construction bricks with clay.

|

|

|

|

• widely used as fuel in industries such as steel and iron factories, ceramics, etc.

|

|

Biogas

|

Daily life

|

• widely used as fuel.

|

|

|

Agriculture

|

• greenhouse agriculture heating.

|

|

|

Industry

|

• used as fuel for heating or drying.

|

|

|

|

• can be used for the generator to get electricity.

|

|

Wood vinegar, Tar

|

Industry

|

• used as permeability-reducing agent for construction.

|

|

|

|

• the great materials in shipbuilding and paint industry.

|

|

|

|

• used as raw materials in chemical and medicine field.

|

|

|

Agriculture

|

• Anti-insect fungicide, pesticide neutralization, soil conditioner.

|

|

|

|

• used as plant nutrition regulates auxin or insecticide.

|

Packing & Shipping

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Gold Services

If you want low price Continuous carbonization furnace charcoal making machine or our machine quotation,please contact us freely.We assure to contact you within 24hrs:

(A) Pre-sale services: Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

1.Select equipment model;

2.Design and manufacture products according to clients' special requirement;

3.Train technical personnel for clients;

4.Send technician to the mine site to guide the installation, trial run test, and training operators until the plant works normally.

(B)After-sale services: Provide considerate services to minimize clients' worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4.Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide perfect service;

7.Provide technical exchanges;

8.Equipment warranty is 12 months, Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed...

Hot Searches