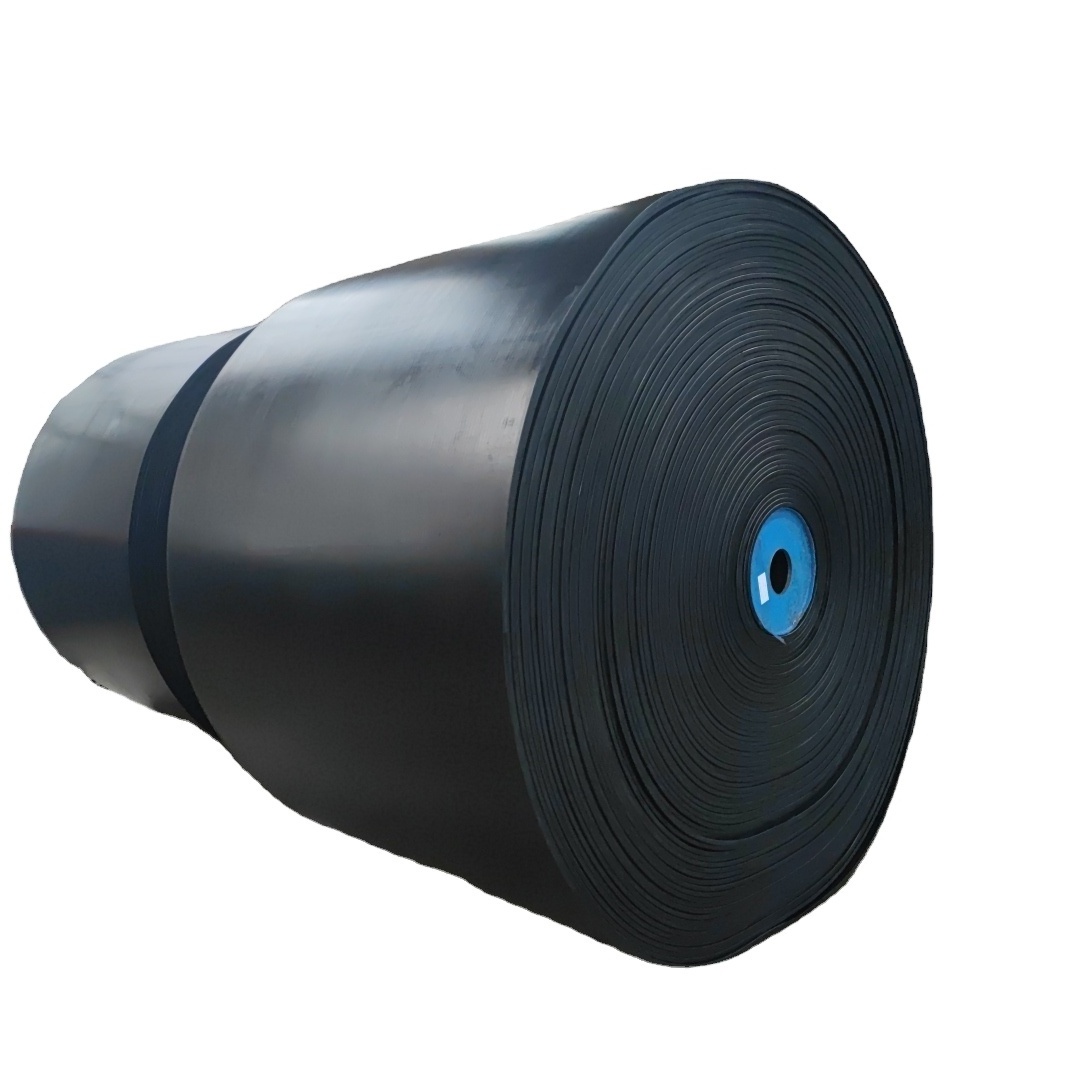

Acid and alkali resistant conveyor belt is used for material delivery in chemical,

paper, cement, fertilizer and other industries.

Characterstics :

1)Prevent corrosion of acid or alkali;

2)Good adhesion properties without delamination;

3)The core material can use cotton, polyester, nylon, polyester and other materials.

Applicable standards HG/T3782-2015.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ccj-07

-

Product Name:

-

Chemical Resistant Conveyor Belt

-

Application:

-

Chemical/Paper/Cement/Fertilizer

-

Type:

-

A1-A3

-

Belt width:

-

500-2500mm

-

Material:

-

ST/EP+Rubber

-

Color:

-

Black

-

Standards:

-

HG/T 3782-2015

-

Size:

-

Customer's Requirements

-

Quality:

-

High Level

-

Advantage:

-

Anti Acid and Alkali

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ccj

-

Model Number:

-

ccj-07

-

Product Name:

-

Chemical Resistant Conveyor Belt

-

Application:

-

Chemical/Paper/Cement/Fertilizer

-

Type:

-

A1-A3

-

Belt width:

-

500-2500mm

-

Material:

-

ST/EP+Rubber

-

Color:

-

Black

-

Standards:

-

HG/T 3782-2015

-

Size:

-

Customer's Requirements

-

Quality:

-

High Level

-

Advantage:

-

Anti Acid and Alkali

Other Recommendations for Your Business

Product Description

|

Product Model

|

CCJ-07

|

|

Product Name

|

Acid and alkali resistant conveyor belt

|

|

Skeleton material

|

Fabric/textile/steel cord

|

|

Size

|

Custom

|

ACID AND ALKALI RESISTANT CONVEYOR BELT

Cover rubber acid and alkali resistant performance lndex

|

Terms

|

Soaking Solution

|

Concentration

|

Soaking Condition Temperature✖ Time

|

The rate of change before/after soaking

|

|

|

|

|

|

|

|

Expansion Rate

|

Strength Rate

|

|

|

A1

|

HCl

|

18%

|

50℃✖96h

|

under +10%

|

within -10%

|

|

|

A2

|

H

2

SO

4

|

50%

|

50℃✖96h

|

under +10%

|

within -10%

|

|

|

A3

|

NaOH

|

48%

|

50℃✖96h

|

under +10%

|

within -10%

|

|

Cover Rubber Physical Performance

|

Item

|

|

Index

|

|

|

|

|

Range of Cariation

|

|

|

Hardness

|

Before aging(IRHD)

|

60

+10

-5

|

|

|

|

Difference between befor and after aging(IRHD)

|

20

|

|

|

|

Maximum after aging(IRHD)

|

85

|

|

|

Tensile Strength

|

Minimum before aging/MPa

|

15

|

|

|

|

Change rate after aging/%

|

-25

|

|

|

|

Minimum after aging/MPa

|

12

|

|

|

Elongation at break

|

Minimum before aging /%

|

400

|

|

|

|

Change rate after aging/%

|

-50

|

|

|

|

Minimum after aging/%

|

200

|

|

|

Abrasion

|

Before aging/mm³≤

|

200

|

|

CMH Offers Rubber Conveyor Belts with Different Characteristics

Heat Resistant Conveyor Belt

Oil Resistant Conveyor Belt

Cold Resistant Conveyor Belt

Anti-tear Conveyor Belt

Low Rolling Resistance(LRR) Conveyor Belt

Pipe Conveyor Belt

Production Process and Quality Control

Step 1:

Raw material inspection

Rubber Compound test

ST Steel Cord Test

Step 2:

Advance equipment to guarantee quality from the details

Mixing

process

Rubber is a mixture of a variety of ingredients, but the strong viscosity of rubber leads to various ingredients are difficult to directly mix evenly, need to be added to the mixer repeatedly stirred, mixed evenly.

Calendering process

The heated mixed rubber is produced into the desired rubber sheet semi-finished product by rotating and horizontally setting the gap between two rollers in a relative and horizontal manner.

Forming process

The rubber sheet semi-finished product obtained by calendering is made into the required semi-finished product by the forming mechanism according to different specifications.

Step 3:

Vulcanization Process

Step 4: Finished Product and

Technical data test

Finished belt

Relative inspection in production

Test the appearance, size, mechanical properties and other aspects of the conveyor belt produced to ensure that it meets the standard requirements.

Application

Ports

Cement

Quarry

Steelworks

Copper mine

Power Plant

Hot Searches