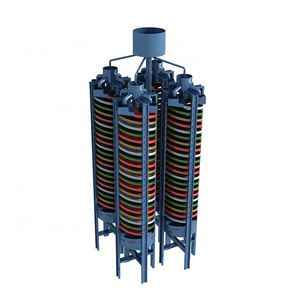

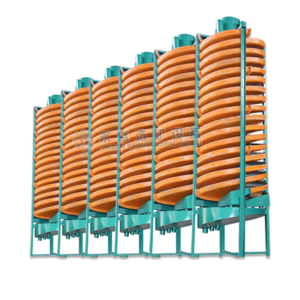

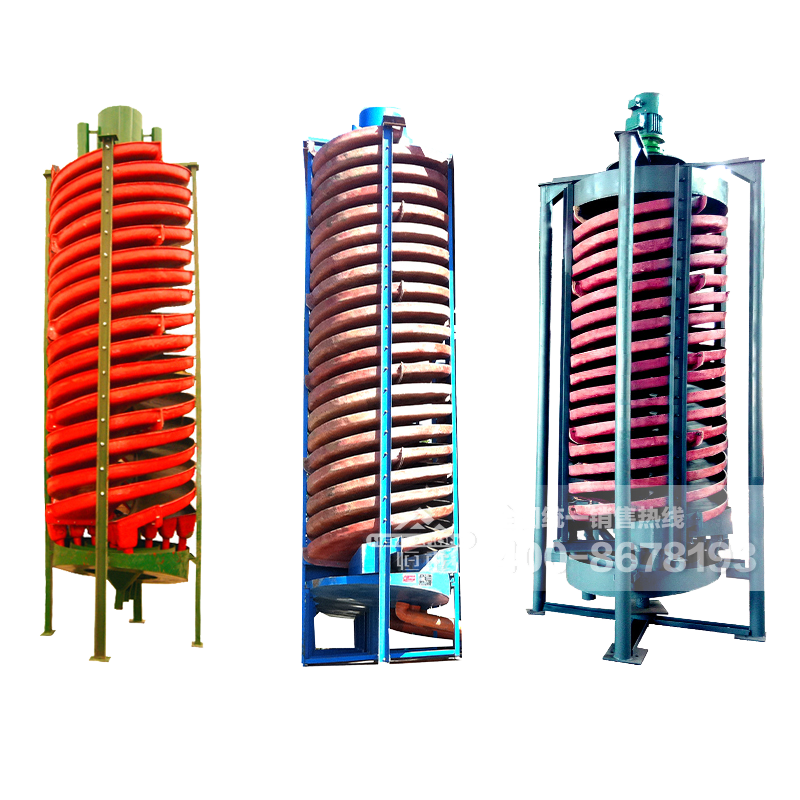

1. Reasonable structure and small occupation area;

2. High recovery, high efficiency, and precise separation;

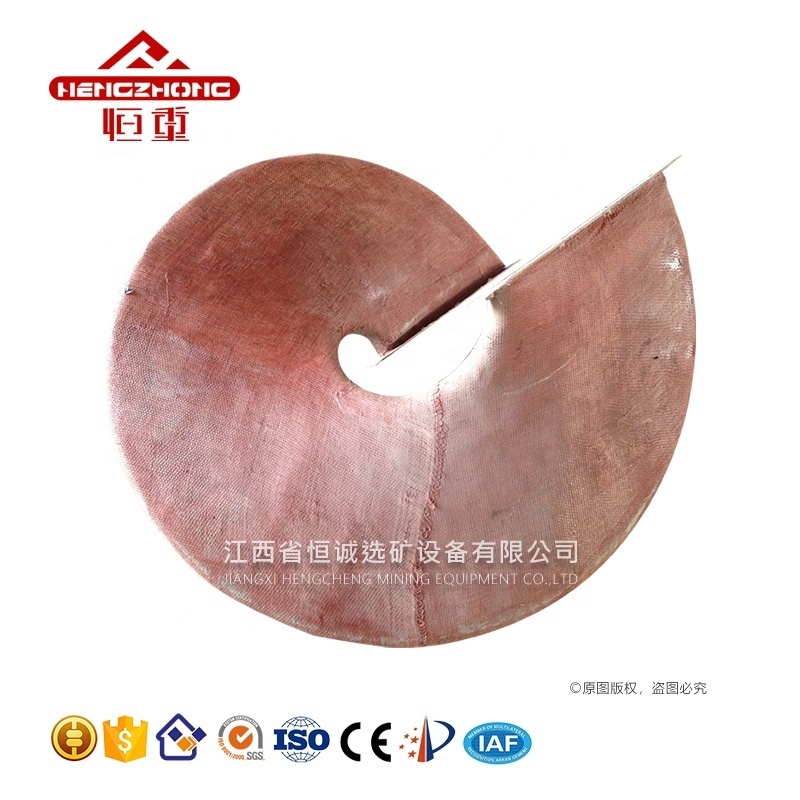

3. Light in weight, rust and corrosion resistant;

4. Simple installation and Minimal maintenance requirements;

5. Low operating cost and long operating life;

6. Reliable running with minimal operator attention;

7. Strong adaptability to fluctuation of feeding amount, density, size and grade.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

/

-

Dimension(L*W*H):

-

1360*1360*5230

-

Weight:

-

600 KG, 600 kgs

-

Capacity:

-

4-6 tph

-

Outside Diameter:

-

1200 mm

-

Pitch:

-

900, 720, 540 mm

-

Lateral Slope:

-

9 degrees

-

Maximum Starts Per unit:

-

4-2

-

Feeding size:

-

0.3-0.03 mm

-

Feeding density:

-

25-55%

Quick Details

-

Production Capacity:

-

500 sets per month

-

Place of Origin:

-

Jiangxi

-

Brand Name:

-

Hengzhong

-

Voltage:

-

/

-

Dimension(L*W*H):

-

1360*1360*5230

-

Weight:

-

600 KG, 600 kgs

-

Capacity:

-

4-6 tph

-

Outside Diameter:

-

1200 mm

-

Pitch:

-

900, 720, 540 mm

-

Lateral Slope:

-

9 degrees

-

Maximum Starts Per unit:

-

4-2

-

Feeding size:

-

0.3-0.03 mm

-

Feeding density:

-

25-55%

Product Overview

DESCRIPTION

Spiral separator (spiral chute) is one of the gravity concentrators, which separate minerals of different specific gravity according to their relative movement in response to gravity, centrifugal force and other forces in the fluid medium. Spiral chute is widely applied to mineral separating of size 0.3 - 0.02 mm, such as ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphate, tungsten ore, tin, tantalum, niobium ore and other non-ferrous metals, precious metals and non-metallic minerals.

PRODUCT SPECIFICATIONS

|

Model

|

Outside Diameter (mm)

|

Screw Picth (mm)

|

Heads Number

|

Feeding size (mm)

|

Capacity (t/h)

|

Weight (kg)

|

Dimension (mm)

|

|

BLL-1500

|

1500

|

900,675

|

2-4

|

0.3-0.02

|

8-6

|

1100

|

1600*1600*4510

|

|

BLL-1200

|

1200

|

900,720,540

|

2-4

|

0.3-0.03

|

4-6

|

800

|

1360*1360*5230

|

|

BLL-900

|

900

|

675,540,405

|

2-4

|

0.2-0.02

|

2-3

|

400

|

1060*1060*4000

|

|

BLL-600

|

600

|

450,360,270

|

3

|

0.2-0.02

|

0.8-1.2

|

150

|

700*700*2600

|

|

BLL-400

|

400

|

240,18

|

2

|

0.2-0.02

|

0.15-0.2

|

50

|

460*460*1500

|

Working Principle

Spiral chute is working under the force of water flow, gravity, inertial centrifuge and friction. Slurry is pumped to the top of

the spiral, and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles are carried with the bulk of the water towards the outside of the spiral, while particles with the greatest density migrate towards the inside of the spiral.

the spiral, and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles are carried with the bulk of the water towards the outside of the spiral, while particles with the greatest density migrate towards the inside of the spiral.

Features of Spiral Chute

Successful Project

Packing & Shipment

Packing and Delivery

1. All the goods will be delivered in 15-30 working days after receiving payment.

2. The machine will be packed in an export container.

3. Motors and small parts will be packed in new strong wooden cases that are suitable for long-distance ocean transportation.

4. We promise that your goods will be shipped to your destination timely and safely.

Recommend Products

Hot Searches