- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±1%

-

Voltage:

-

110V/220V/380V/,50HZ/60HZ

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Weight:

-

50 KG

-

Function:

-

Quantitative Volume Filling

-

Filling volume:

-

10-100000ml

-

Material:

-

Stainless Steel 304/316

-

Hopper size:

-

10-100L

-

Working speed:

-

10-60bottles/min(based on 250ml jam)

-

Air pressure:

-

0.4 ~ 0.9Mpa

-

Drive control form:

-

PLC precise pulse control of servo motor

-

Suitable for:

-

High Viscous Products

-

Packing speed:

-

10~20Pcs/min

-

Tags:

-

Filling machines/low speed filling machine/Liquid Filling Machine

Quick Details

-

Machinery Capacity:

-

Other

-

Packaging Material:

-

Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Powder, Other

-

Filling Accuracy:

-

≤±1%

-

Voltage:

-

110V/220V/380V/,50HZ/60HZ

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Weight:

-

50 KG

-

Function:

-

Quantitative Volume Filling

-

Filling volume:

-

10-100000ml

-

Material:

-

Stainless Steel 304/316

-

Hopper size:

-

10-100L

-

Working speed:

-

10-60bottles/min(based on 250ml jam)

-

Air pressure:

-

0.4 ~ 0.9Mpa

-

Drive control form:

-

PLC precise pulse control of servo motor

-

Suitable for:

-

High Viscous Products

-

Packing speed:

-

10~20Pcs/min

-

Tags:

-

Filling machines/low speed filling machine/Liquid Filling Machine

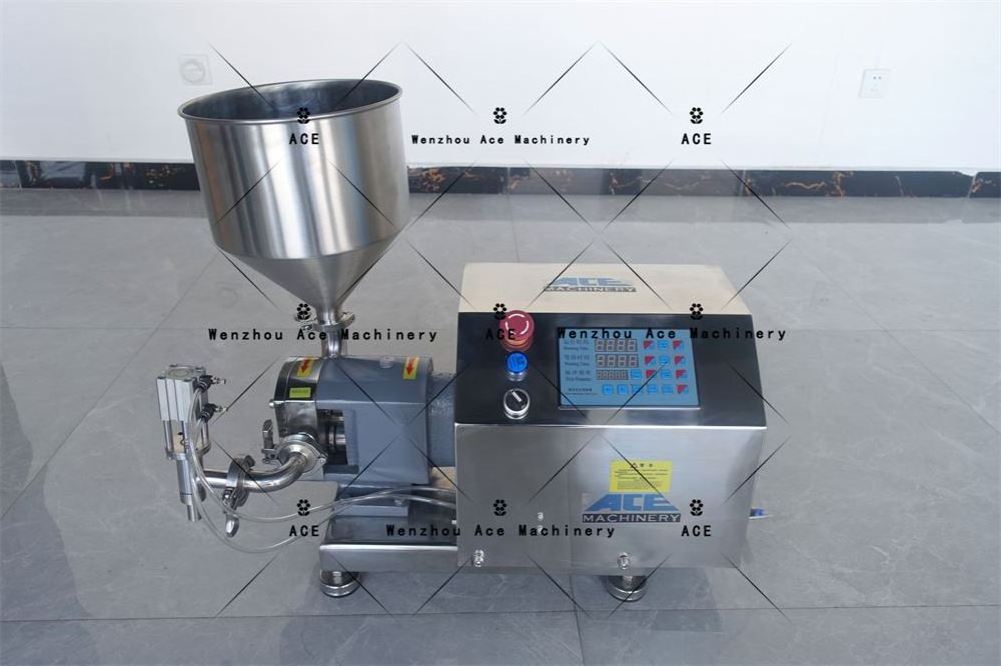

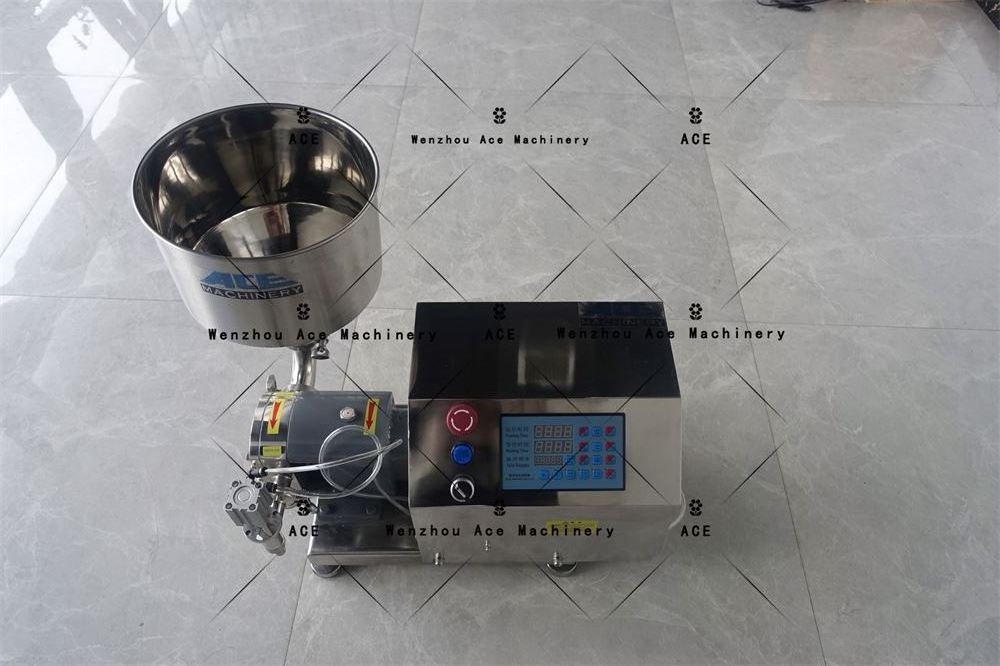

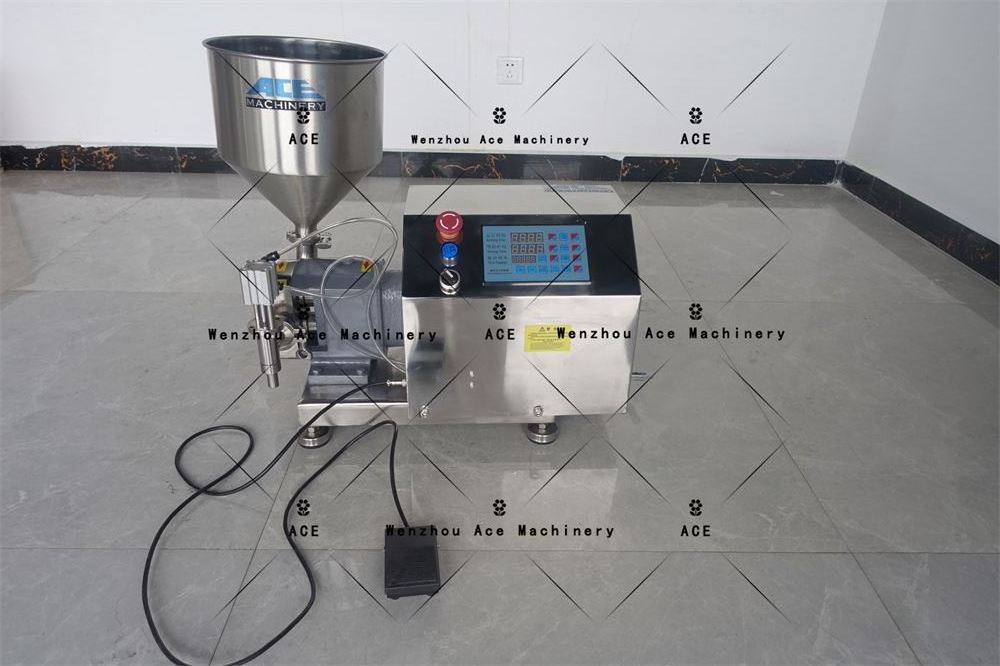

Automatic Servo Lobe Gear Pump Liquid Super Adhesive Glue Small Bottle Filling And Capping Machine

22 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products.15-30 day fast delivery. Please contact us for the offer.

Video

Products Description

Equipment Description

The main function of semi-automatic filling machine is filling, less with other functions, especially suitable for seasoning with granules and large concentration of chili sauce, bean sauce, peanut butter, sesame sauce, jam, and other substances of the thick sauce filling. The advantages of the equipment can be accurately measured by the two performance indexes of filling speed and measurement accuracy.semi-automatic high efficiency filling machine is undoubtedly the ideal equipment in the filling machine

Features:

1. Equipped with rotor pump, the machine is small and powerful in function.

2. Large filling range, filling range from 5ml to 30L.

3. The machine is made of 304 stainless steel, which is food grade.

4. Servo motor drives rotor pump, high filling accuracy.

5. PLC and touch screen control panel, easily adjust various filling parameters.

This series of filling machines have reasonable structure, compact models, reliable performance, accurate quantification, and convenient operation. The contact parts are made of 304L stainless steel, which meets the requirements of GMP certification. The filling head adopts anti-drip and lifting filling device

|

Model

|

ACE-GZJ-A1

|

|

Filling range

|

5ml-30L

|

|

Rate of flow

|

250ml/s

|

|

Filling Accuracy

|

±0.5%

|

|

Air Pressure

|

0.4-0.6MPa

|

|

Required Air Compressor

|

≥1.5KW 65L

|

Reference Rotating Speed

|

Material

|

Rotating Speed

|

Material

|

Rotating Speed

|

Material

|

Rotating Speed

|

|

Noodle pulp

|

4-6

|

Peanut butter

|

2-8

|

Bean Paste

|

5-10

|

|

Industrial butter

|

3-4

|

Chili sauce

|

5-10

|

Jam

|

10-15

|

|

Juice

|

10-20

|

Chocolate

|

10-15

|

laundry detergent

|

10-20

|

|

Cooking oil

|

10-20

|

Milk

|

10-20

|

Toothpaste

|

10-15

|

|

Cream

|

10-18

|

Salad dressing

|

5-10

|

Hand Cream

|

10-20

|

|

Cheese

|

5-10

|

Honey

|

5-10

|

Resin

|

2-6

|

|

Tomato Paste

|

10-20

|

hotpot condiment

|

5-10

|

white emulsion

|

2-6

|

Application:

Servo filling machine is used for shampoo, detergent, toothpaste, glycerin, pigments, additives, adhesives, chemical fibers: polyester fiber, man-made fiber, polypropylene fiber. Coating: paint, ink, resin, chocolate, syrup, cream, mayonnaise, jam

Cosmetics: creams and lotions, hair sprays, essential oils.

Details Images

Rotor pump

Rotary pump filling has the advantages of small size, fast filling speed, and wide adjustable range of filling volume.

Note: Idling will damage the rotor pump

PLC control panel

PLC and touch screen control panel, easily adjust various filling parameters.

Hopper

The hopper is made of 304 stainless steel, food grade

If the material has low viscosity, it can also be connected to the pipeline

If the material has low viscosity, it can also be connected to the pipeline

Filling nozzle

Filling nozzle with anti-drip function

Made of 304 stainless steel, food grade

Made of 304 stainless steel, food grade

Certifications

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6.Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact Us

Hot Searches