- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JOBEST MACHINERY

-

Power (kW):

-

11

-

Weight (KG):

-

3500

-

Marketing Type:

-

Hot Product 2024

-

Machine Type:

-

Pipe and Tube Bending Machine

-

Raw Material:

-

PIPE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Key Words:

-

Rolling Pipe Bending Machine

-

PLC:

-

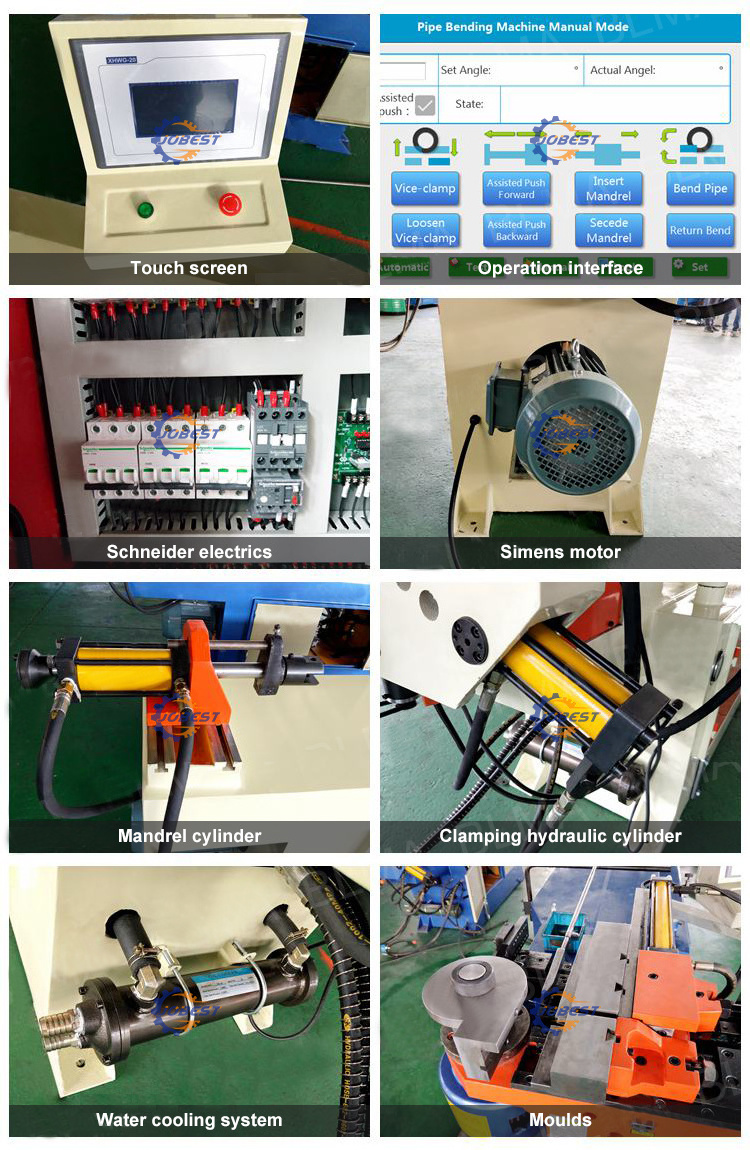

OMRON

-

Servo motor:

-

Mitsubishi, JAPAN

-

Electrical Parts:

-

SCHNEIDER, FRANCE

-

Hydraulic Parts:

-

YUKEN, JAPAN

-

Application:

-

Pipes Processing

Quick Details

-

Max. Bending Angle (Deg):

-

185

-

Bending Precision (Deg):

-

±0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JOBEST MACHINERY

-

Power (kW):

-

11

-

Weight (KG):

-

3500

-

Marketing Type:

-

Hot Product 2024

-

Machine Type:

-

Pipe and Tube Bending Machine

-

Raw Material:

-

PIPE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Key Words:

-

Rolling Pipe Bending Machine

-

PLC:

-

OMRON

-

Servo motor:

-

Mitsubishi, JAPAN

-

Electrical Parts:

-

SCHNEIDER, FRANCE

-

Hydraulic Parts:

-

YUKEN, JAPAN

-

Application:

-

Pipes Processing

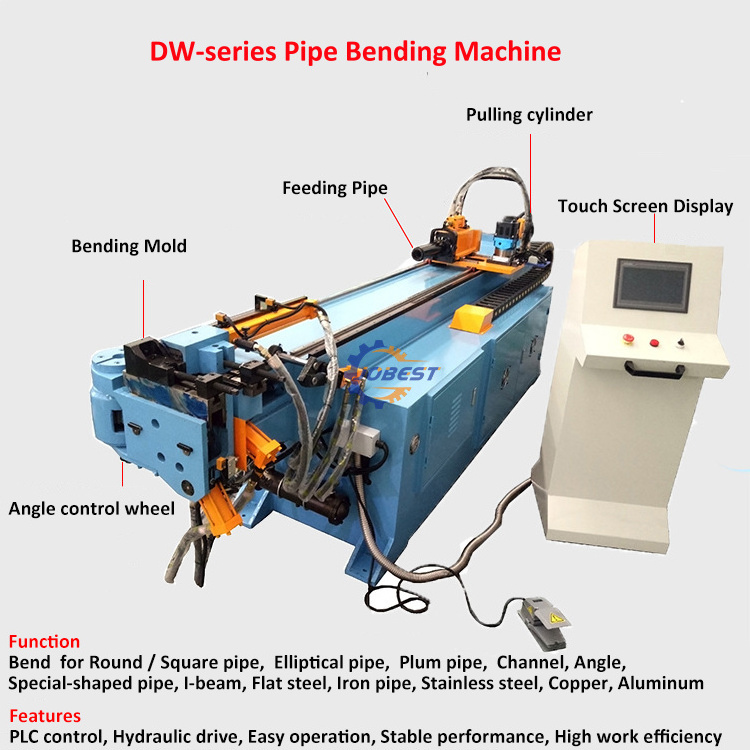

- Bend-arm (C-axis) by hydraulic . Clamp die by hydraulic, Pressure die by hydraulic.

- Carriage (Y-axis) by servo motor . Collet (B-axis) : rotation by servo motor, grip by hydraulic.

- Anticipated mandrel retraction unit. Standing pedestal, serves emergency stop and remote control

- Fan -cooling system. Diagnosis error immediately.

- Central Automatic lubrication system.

- Foot pedal for safe start.

- It is fully automatic pipe bending machine, with PLC control system, two servo for rotary, feeding.

- Touch screen panel display English, have different bending degree prefabricate, dialogue operation, can choose manual, semi-automatic and full automatic operation manual, portable pedal switch with start and emergency stop function. Multi axes working simultaneously.

- Bending pipe — Automatic . Rotating pipe — Automatic. Feeding pipe — Automatic.

- One key back up of programs for USB or disk storage or through INTERNET. Management and storage of bend data and tools is done in standard text files on the hard disk of the control PLC. In case of requirement it is also possible to integrate the PLC into bending machine. Therefore an Ethernet adapter is included. The number of tools and products is practically unlimited. Product and tool files can easily be edited (also on a separate PLC) and printed out.

- Security code for the protection the data setting and selected operation features.

- To access to history bending setting data to facilitate study of malfunction with one set of tooling.

- All the parts of hydraulic system, control system, driver system and display system are imported from famous brand , with high accuracy, high efficient, suitable for mass production.

- CNC fully auto , have cubical space bending equipment, loading the whole bending process is automatic.

- The machine is convenient operation, stable performance and high safety factor. The machine is ideal choice for pipe processing.

- CE, ISO9001, SGS Certification .

- Interactive PLC touch screen offers easy access to auto and manual operating modes.

- System diagnostics and multiple language capability.

- Standard clockwise bending direction.

- Fully hydraulic clamping on clamp die and pressure die.

- Drop-way hydraulic clamping.

- Direct acting hydraulic pressure die with adjustable speed valve.

- Maximum 100 sets of program storage, Maximum 32 bends for each program.

- With Independent programmable speeds Y, B, and C axes.

- Programmable material spring back settings for each bend angle.

- Automatic release of tube prior to final bend.

- Bending Axis - Driven by Cylinder, Feeding Axis - Driven by Servo Motor, Rotating Axies - Driven by Servo Motor.

- Obtain quality repeatable bends in steel, stainless, aluminum, titanium and brass.

- Foot Pedal Cycle start.

- With Air Cooling System / Water Cooling System .

- One set of Tooling for Draw Bending.

- Wiper die Bracket.

- 1 Mandrel Rod.

- Operation and Maintenance Manual.

- Tool Box with Adjusted Tools.

- Electric: As required (3 phase 220V or 380V or 415V...)

Optional choose for our CNC pipe bending machine

- Industrial Computer Controlling

- Anticipate Mandrel Extraction

- Automatic mandrel /machine lubrication

- Anti-clockwise bending direction

- Machine effective length over mandrel

- Safety Mat

WHY CHOOSE US - JOBEST MACHINERY?

Pre-sale:

(1) Regarding your demands, the best suitable machine will be recommend you, the customized machine also support;

(2) Regarding your country requirements, some certificates will supply to help you clearance. Like CE,CO, FORM-A, FORM-E, FORM-F, original certificate signed by Embassy.etc.

(3) All the machine will be tested before delivery, and we will take the video and pictures to you. When you receive it , it can work directly.

After-sales

(1) We will supply all the control system and software operate manual,so you can operate the machine easily refer it.

(2) All the machine problem , you can ask me any time , we will help you solve by online way ,or tel,email,remote video at first time ,if all these can’t solve your problem , our engineer will go to your factory to help you on spot.

Welcome to our factory for learning how to operate machine ,one professional engineer will together with you , this service for free.

Guarantee:

One year for whole machine , any parts except consumables broken regarding machine quality within one year,We will send you the parts for free.

All the service is for machine whole life.

Nantong Jobest Machinery Technology Co., Ltd founed in 1998, is a leader Manufacturer Factory of Metal Forging Machine. Such as Shearing Machine, Press Brake Machine, Plate Rolling Machine, Profile Bending Machine, Hydraulic Press Machine, Notching Mahine, Iron Worker Machine, Laser Cutting Machine, etc. Meanwhile we're familiar with kinds of Processing Machines to help our clients choose the most suitable machine on the best quality by economically.

1. How i can choose a suitable Hydaulic Machine?

Tell us your detailed requirements,

we can help choose the

best suitable machine

.

2. Are you the manufacture?

Yes, we are

manufacturer factory

, so you can get factory price directly. Don't need pay some extra agent price.

3. Can we visit your factory?

Yes, of course ,

welcome

you visit our factory and check our machine qualtiy on spot. After you confirm the coming time , tell me in advance, then we will go to air port or train station to pick you up on time.

And one professional will together with you in the factory , any question will be solved on spot

at first time

.

4. Any benefits can we get if introduce new customer to you ?

Yes, of course, some gifts you will get, and the

commission

regarding the new customer amount.

5. Can we be your agent?

Welcome , we are looking for

Global agent

we will help agent improve the market ,and supply all the service like machine technical problem or other after-sales problem, meanwhile ,you can get big discount and commission.

6. Payment terms?

T/T, L/C, Western Union, Paypal, Alibaba Secure Payment ect.

B

uyer pays

30%

by T/T to start this order

, rest

70%

paid before shipment.

7. How can you gunarantee the quality?

Professional product quality inspection team ensure our plasma cutting machine in top-quality.

Otherwise, we take full responsibility according to our wholesale after-sale support system

8. I want to buy this machine, what suggestion can you give?

Please tell me what material do you process? What's the size of your material?

JOBEST MACHINERY: BEST-QUALITY, BEST-SERVICE, BEST-PRICE!!! SEND INQUIRY