- Product Details

- {{item.text}}

Quick Details

-

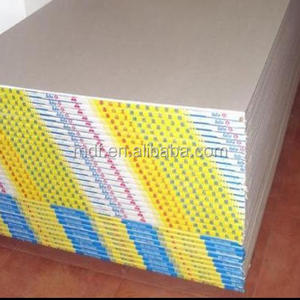

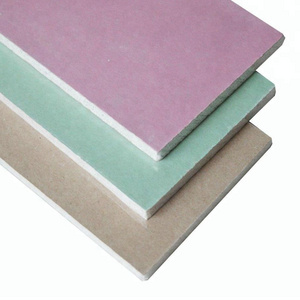

Product Name:

-

Plasterboard Gypsum Ceiling Board Sheetrock Drywall

-

Raw Material:

-

High Purity Gypsum Powder

-

Usage:

-

Internal Wall Partition

-

Certificate:

-

CE/ISO9001

-

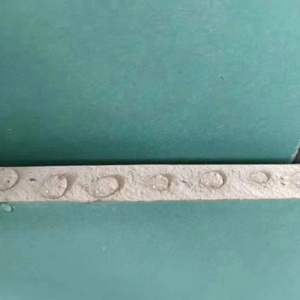

Function:

-

Paper Faced Gypsum Board.Firepr

-

Specification:

-

Thickness:6.4-25MM Length:595-3000mm Width:595--1220mm

-

Type:

-

Paperbacked Plasterboards

-

Edge:

-

Square Edge

-

Brand:

-

Deyi

-

Advantage:

-

Environment

Quick Details

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Office Building

-

Product Name:

-

Plasterboard Gypsum Ceiling Board Sheetrock Drywall

-

Raw Material:

-

High Purity Gypsum Powder

-

Usage:

-

Internal Wall Partition

-

Certificate:

-

CE/ISO9001

-

Function:

-

Paper Faced Gypsum Board.Firepr

-

Specification:

-

Thickness:6.4-25MM Length:595-3000mm Width:595--1220mm

-

Type:

-

Paperbacked Plasterboards

-

Edge:

-

Square Edge

-

Brand:

-

Deyi

-

Advantage:

-

Environment

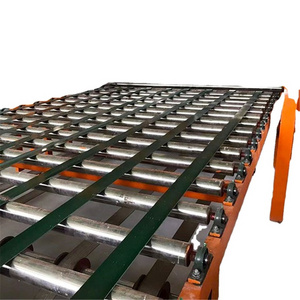

full automatic paper faced gypsum board manufacturing production line price

Product specification

Board length: 1800--3600mm

Board width: 1200mm , 1220mm

Board thickness: 8--25mm

This quotation is on basis of general gypsum plaster board length 2400mm, width 1200mm, thickness 9.5

Main production process parameters

| Max running speed of solidifying belt machine | 22m/min |

| Runing time from mixer to cutter Runing time from mixer to cutter | 4.5min |

| Max running speed of dryer Max running speed of dryer | 1.3m/min |

| Dryer evaporation capacity | 4.5t water /h |

| Moisture content of gypsum board after drying | ~ 1% |

Forming section

Q: . Why I choose your company?

A:

a) We have made foam machine about 30 years with strong experience and advanced technics.

b) Best Quality & Best Service with Competitive price.

c) 100% inspection Before Shipment

d) We have Professional technical team, supply 24 hours service.

e) One year guarantee and lifetime maintenance.

Q : What should we prepare except material?

A : You should prepare workshop, water line, electric line, compress air (if you need, we can help you buy air compressor).

We can supply workshop layout drawing according to your workshop.