- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PTFE Sheet 01

-

Thickness:

-

0.5-150mm

-

Size:

-

600*600/1000*1000*1200*1200mm

-

Model Number::

-

PTFE board

-

Feature::

-

High temperature and wear resistance

-

Technology available::

-

Engraving processing CNC lathe processing

-

Color::

-

White/black

-

Delivery time::

-

3-15days

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BOYIDA

-

Model Number:

-

PTFE Sheet 01

-

Thickness:

-

0.5-150mm

-

Size:

-

600*600/1000*1000*1200*1200mm

-

Model Number::

-

PTFE board

-

Feature::

-

High temperature and wear resistance

-

Technology available::

-

Engraving processing CNC lathe processing

-

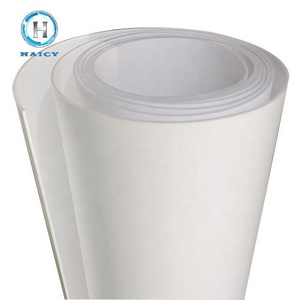

Color::

-

White/black

-

Delivery time::

-

3-15days

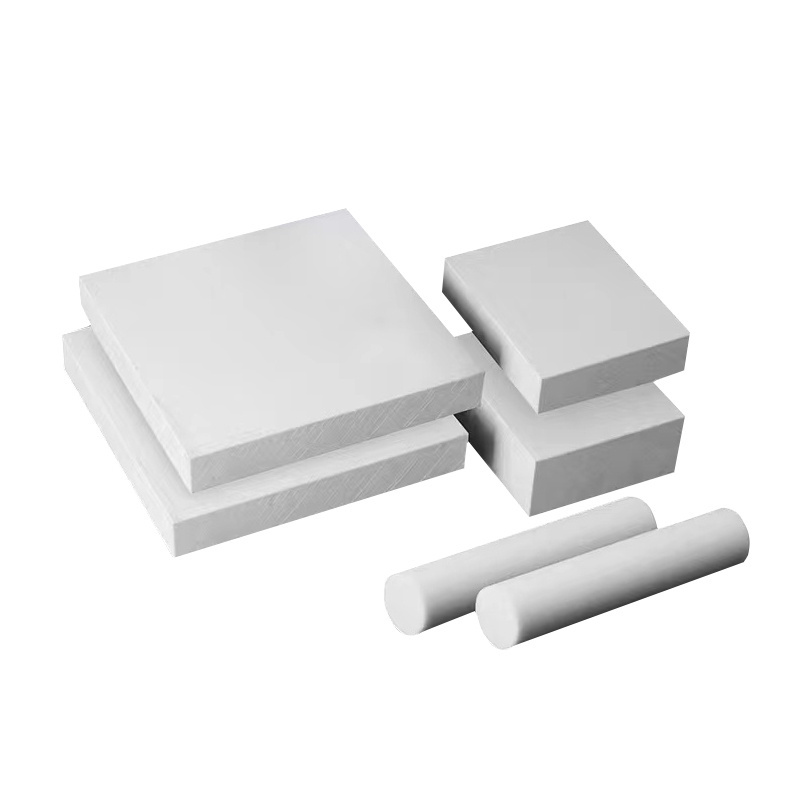

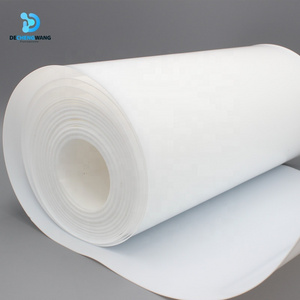

Products Description

|

Product name:

|

|

|

PTFE sheet / PEFE bar

|

|

|||

|

model:

|

|

|

PTFE

|

|

|||

|

Colour:

|

|

|

White/black

|

|

|||

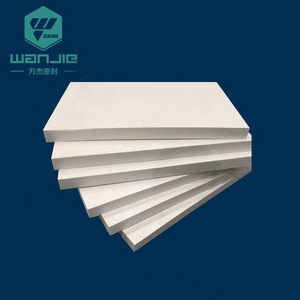

|

Sheet size:

|

|

|

600*600mm/1000*1000mm/1200*1200mm

|

|

|||

|

Sheet thickness:

|

|

|

0.5-150mm(Customizable)

|

|

|||

|

service:

|

|

|

support customization,arbitrary cutting,free sampling

|

|

|||

|

Diameter of round rod:

|

|

|

8-360 diameter*1000mm

|

|

|||

►

Plastic parts and materials (PTFE)

PTFE(Poly Tetra Fluoro Etylene) has excellent heat resistance (about -250 to 260℃), chemical resistance,

abrasion resistance, and outstanding chemical resistance.

It also has water-repellent, non-adhesive properties, much better slidability than other plastics. T he surface feels very smooth.

We can process the JIS-certified PTFE material into

various shape such as plate, round bar, pipe. also welding and permeabilizing treatment.

various shape such as plate, round bar, pipe. also welding and permeabilizing treatment.

Please send us drawings, pictures, or your preference conditions.

We will respond quickly and give you the best answer.

FAQ

Q1. We don't have drawings, can we produce according to the samples we provide?

A1. Yes.

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. Yes.

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine,

injection molding machine, extruder, molding machine.

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as

machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface

treatments?

A7.Yes. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8.Yes.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the

lowest temperature is -40℃, and the highest temperature is 328℃. We

can recommend materials according to the working conditions of your

company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent

certificates, etc.

Hot Searches