- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw, 1.5 kw

-

Dimension(L*W*H):

-

1400*700*2000mm

-

Weight:

-

250 KG

-

Machinery Function:

-

sesame washing cleaning peeling and separation

-

Raw material:

-

Sesame

-

Output product name:

-

peeled sesame

-

Material:

-

304 Stainless Steel

-

Function:

-

washing and peeling

-

Peeling motor:

-

2.2kw

-

Separating motor:

-

1.5 kw

-

Hull removing rate:

-

80%-85%

-

Feature:

-

Compound Agitator

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

-

Processing:

-

Sesame Seeds Cleaning Peeling

-

Application:

-

Sesame Seeds

Quick Details

-

Brand Name:

-

Taizy

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V or as customer requipment

-

Power:

-

2.2kw, 1.5 kw

-

Dimension(L*W*H):

-

1400*700*2000mm

-

Weight:

-

250 KG

-

Machinery Function:

-

sesame washing cleaning peeling and separation

-

Raw material:

-

Sesame

-

Output product name:

-

peeled sesame

-

Material:

-

304 Stainless Steel

-

Function:

-

washing and peeling

-

Peeling motor:

-

2.2kw

-

Separating motor:

-

1.5 kw

-

Hull removing rate:

-

80%-85%

-

Feature:

-

Compound Agitator

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

-

Processing:

-

Sesame Seeds Cleaning Peeling

-

Application:

-

Sesame Seeds

Products Description

Description of Sesame Washing Peeling Machine

1. The sesame washing and peeling machine is composed of a washing cylinder and a peeling cylinder. The barrel is a vertical cylinder, the internal space can be fully utilized, small size, simple structure, beautiful appearance, easy operation, low maintenance rate.

2. A compound agitator is used. This agitator form can produce axial split flow. The radial diverting effect, the material is fully turned, no dead angle. The use of a compound mixer shortens the time of sesame infiltration, peeling, and separation improves production efficiency and improves product quality.

3. The peeling machine is the special equipment for separating sesame skin, which has the advantages of thorough peeling, perfect grain, white, and brightness.

2. A compound agitator is used. This agitator form can produce axial split flow. The radial diverting effect, the material is fully turned, no dead angle. The use of a compound mixer shortens the time of sesame infiltration, peeling, and separation improves production efficiency and improves product quality.

3. The peeling machine is the special equipment for separating sesame skin, which has the advantages of thorough peeling, perfect grain, white, and brightness.

|

Model

|

TZ-120

|

|

peeling motor

|

2.2kw

|

|

Separating motor

|

1.5kw

|

|

Capacity

|

400-500kg/h

4-5T/D (1ton sesame, 3ton water) |

|

Hull removing rate

|

80%-85%

|

|

Size

|

1400*700*2000mm

|

|

Weight

|

250kg

|

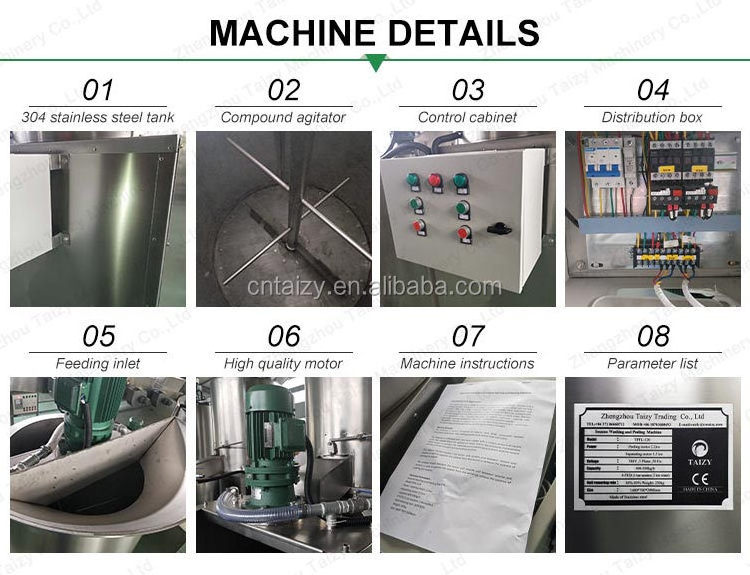

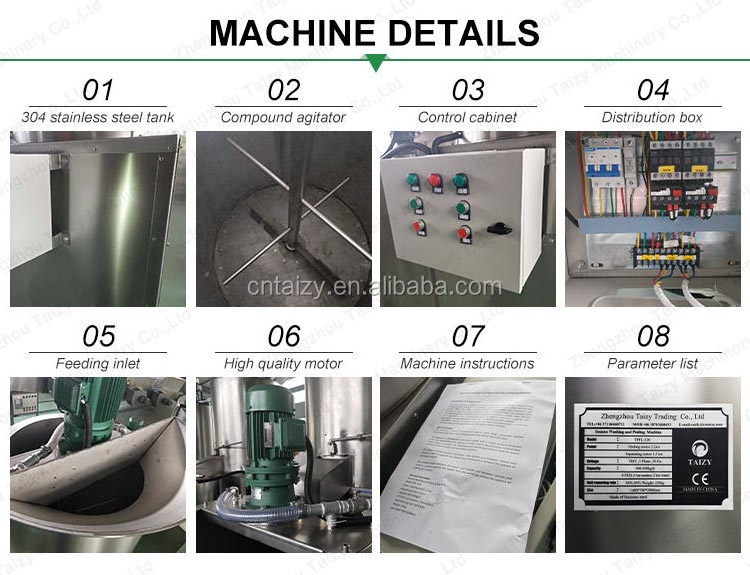

Details Images

Working Principle of Sesame Washing Peeling Machine

1. The sesame peeling washing machine is mainly composed of reducer, tank body, compound agitator, separation sieve plate, water adding pipeline, and various inlet and outlet.

2. The raw material is infiltrated with hot water added with a certain amount of caustic soda. The reducer drives the agitator to rotate. Due to the structural characteristics of the compound agitator, the materials are circulated up and down, and the sesame and the infiltration liquid are mixed evenly and fully.

3. The relative friction between the stirrer and sesame and between sesame and sesame is used to separate the sesame from the kernel to achieve the purpose of peeling the sesame.

2. The raw material is infiltrated with hot water added with a certain amount of caustic soda. The reducer drives the agitator to rotate. Due to the structural characteristics of the compound agitator, the materials are circulated up and down, and the sesame and the infiltration liquid are mixed evenly and fully.

3. The relative friction between the stirrer and sesame and between sesame and sesame is used to separate the sesame from the kernel to achieve the purpose of peeling the sesame.

Why Choose Us

FAQ

1. How long will the transportation take?

Depending on your quantity, for goods, we have in stock. Delivery takes a few days to comply with your request to replace the plug or other configurations. For regular orders, by ocean shipping takes 20-40 days. For small machines, express delivery for 3-8 days.

2. Are you a manufacturer or distributor?

We are an experienced manufacturer and exporter. We own a technical team comprised of over-average experts in R&D and innovation.

Notably, we own high-level factories and cooperating factories that can offer efficient manufacturing and high-end products when dealing with a bulk order.

3. How do I know about the details and quality of your machine?

First, we have product brochures covering all details including parameter, material, output, etc. of most of our production lines;

secondly, we can provide you with videos filmed on-site with details about the working process and how mechanical parts work during operation; at last, you are warmly welcomed for on-site inspection at our factories.

4. What certification do you have?

We have ISO, CE, etc. Please do trust us, we are determined to provide you the best quality equipment.

5. Why choose us?

We have dedicated to the machinery manufacturing industry for more than 10 years with a rare negative response. We are time has proven-- client’s response and comments are the most validated evidence.

Depending on your quantity, for goods, we have in stock. Delivery takes a few days to comply with your request to replace the plug or other configurations. For regular orders, by ocean shipping takes 20-40 days. For small machines, express delivery for 3-8 days.

2. Are you a manufacturer or distributor?

We are an experienced manufacturer and exporter. We own a technical team comprised of over-average experts in R&D and innovation.

Notably, we own high-level factories and cooperating factories that can offer efficient manufacturing and high-end products when dealing with a bulk order.

3. How do I know about the details and quality of your machine?

First, we have product brochures covering all details including parameter, material, output, etc. of most of our production lines;

secondly, we can provide you with videos filmed on-site with details about the working process and how mechanical parts work during operation; at last, you are warmly welcomed for on-site inspection at our factories.

4. What certification do you have?

We have ISO, CE, etc. Please do trust us, we are determined to provide you the best quality equipment.

5. Why choose us?

We have dedicated to the machinery manufacturing industry for more than 10 years with a rare negative response. We are time has proven-- client’s response and comments are the most validated evidence.

Hot Searches