- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4.8 x 2.7 x 1.5 M

-

Year:

-

2020

-

Power (kW):

-

22 kW

-

Weight (KG):

-

5000 KG

-

Applicable Industries:

-

Rubber Roller

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Rubber Hardness Range::

-

15-100SH-A

-

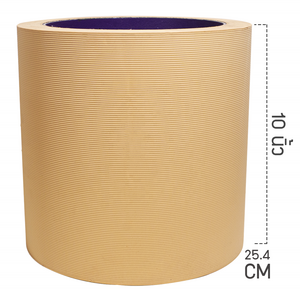

Max Processing Diameter::

-

400mm-2000mm

-

Max Processing Length::

-

3000mm-12000mm

-

Work Piece Weight::

-

500-10000 KGS

-

Suitable Rubber Type::

-

EPDM, NBR, SILICON RUBBER, etc.

-

Feeding Method::

-

Cold feeding

-

Extruder Cooling System::

-

Industrial conditioner cooling and heating

-

Extruder Speed::

-

6.8kg/min

-

Need of operator::

-

1-2 persons

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

POWER

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4.8 x 2.7 x 1.5 M

-

Year:

-

2020

-

Power (kW):

-

22 kW

-

Weight (KG):

-

5000 KG

-

Applicable Industries:

-

Rubber Roller

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Rubber Hardness Range::

-

15-100SH-A

-

Max Processing Diameter::

-

400mm-2000mm

-

Max Processing Length::

-

3000mm-12000mm

-

Work Piece Weight::

-

500-10000 KGS

-

Suitable Rubber Type::

-

EPDM, NBR, SILICON RUBBER, etc.

-

Feeding Method::

-

Cold feeding

-

Extruder Cooling System::

-

Industrial conditioner cooling and heating

-

Extruder Speed::

-

6.8kg/min

-

Need of operator::

-

1-2 persons

-

Certification:

-

CE ISO

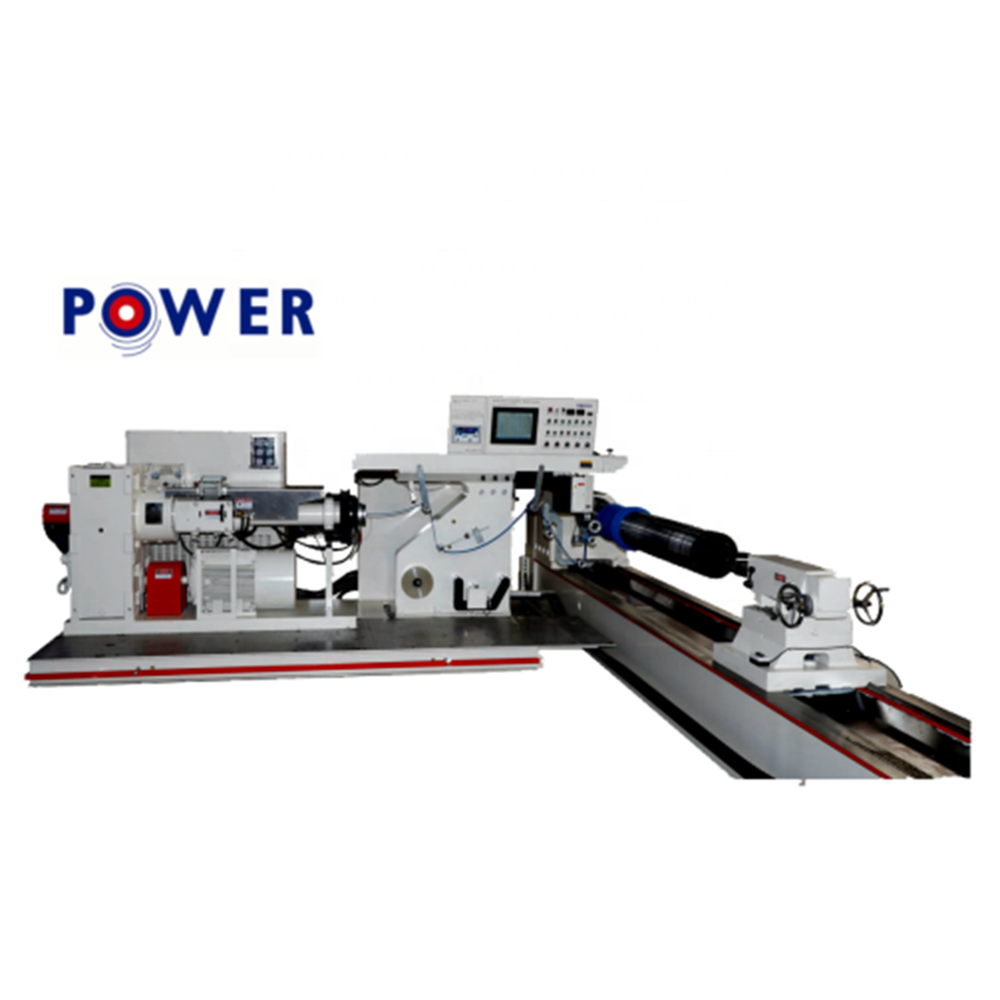

1. The PTM-4030 model is suitable for rubber covering process on printing rollers, general industrial rollers and small industrial rubber rollers.

2. Equipped with E250CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

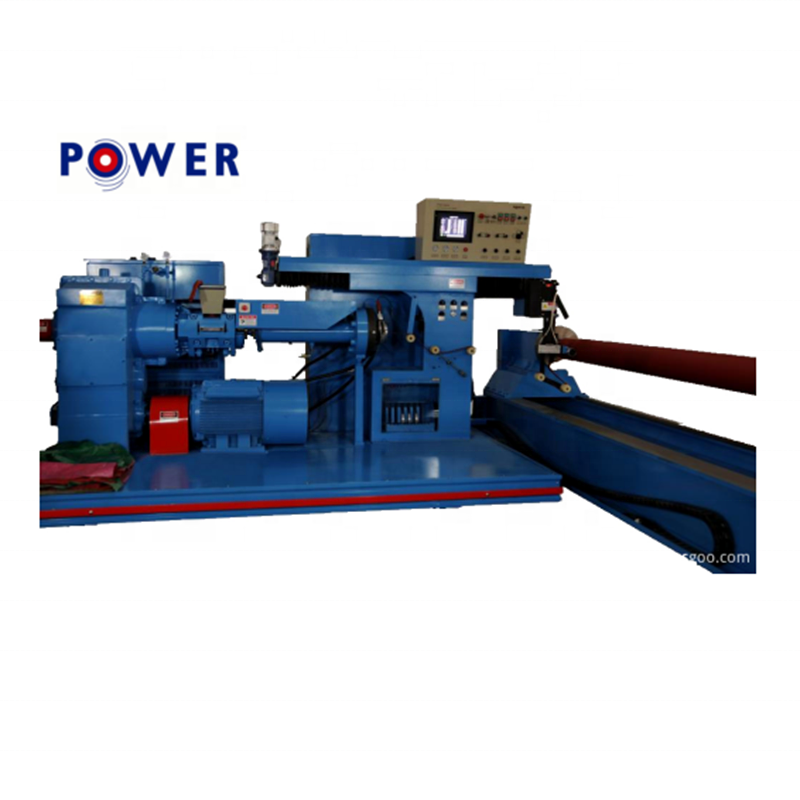

1. The PTM-6040 model is suitable for processing printing rollers, general industrial rollers and small industrial rubber rollers.

2. Equipped with E250CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-8060 model is suitable for processing printing rollers, general industrial rollers and small industrial rubber rollers.

2. Equipped with E300CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-1060/03S model is suitable for processing general industrial rollers and small paper rubber rollers.

2. Equipped with E300CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-1080 model is suitable for processing printing rollers, general industrial rollers and small industrial rubber rollers.

2. Equipped with E300CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-1580 model is suitable for processing big type paper mill, mine transmission and heavy industrial rollers.

2. Equipped with E350CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-1510 model is suitable for processing big type paper mill, mine transmission and heavy industrial rollers.

2. Equipped with E350CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-2010 model is suitable for processing big type paper mill, mine transmission and heavy industrial rollers.

2. Equipped with E350CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

1. The PTM-2012 model is suitable for processing big type paper mill, mine transmission and heavy industrial rollers.

2. Equipped with E350CS power extruder and a complete industrial cooling system.

3. Applicable to rubber compounding with all hardness range 15-100A.

4. Easy Installation with our professional technical support.

5. Optional expansion covering function for special parts of the rubber rollers.

|

MODEL

|

SPECIFICATION

|

MAX. DIAMETER

|

MAX. LENGTH

|

CUBAGE

|

SCREW

|

POWER

|

|

LIGHT

|

PTM-4030

|

16"

400mm

|

118"

3000mm

|

260"*106"*60"

4.8m*2.7m*1.5m

|

2.5"

65mm

|

22KW

|

|

STANDARD

|

PTM-6040

|

24"

600mm

|

157.5"

4000mm

|

260"*118"*63"

6.6m*3.0m*1.6m

|

2.5"

65mm

|

22KW

|

|

HEAVY

|

PTM-8060

|

32"

800mm

|

236"

6000mm

|

300"*126"*63"

7.6m*3.2m*1.6m

|

3"

76mm

|

30KW

|

|

HEAVY

|

PTM-1060/03S

|

40"

1000mm

|

236"

6000mm

|

394"*158"*63"

10m*4.0m*1.6m

|

3"

76mm

|

30KW

|

|

HEAVY

|

PTM-1080

|

40"

1000mm

|

315"

8000mm

|

394"*158"*63"

10m*4.0m*1.6m

|

3"

76mm

|

30KW

|

|

LARGE

|

PTM-1580

|

59"

1500mm

|

315"

8000mm

|

433"*165"*67"

11m*4.2m*1.7m

|

3.5"

89mm

|

45KW

|

|

LARGE

|

PTM-1510

|

59"

1500mm

|

394"

10000mm

|

433"*165"*67"

11m*4.2m*1.7m

|

3.5"

89mm

|

45KW

|

|

LARGE

|

PTM-2010

|

79"

2000mm

|

394"

10000mm

|

472"*181"*71"

12m*4.6m*1.8m

|

3.5"

89mm

|

55KW

|

|

LARGE

|

PTM-2012

|

79"

2000mm

|

472"

12000mm

|

472"*181"*71"

12m*4.6m*1.8m

|

3.5"

89mm

|

55KW

|

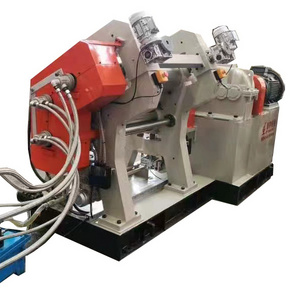

The automatic rubber roller covering machine is designed and produced for improving the rubber covering process. Appropriate models can be selected for different industries. Advanced and mature technology will bring higher efficiency to the roller production.

1.Installation service.

2.Maintenance service.

3.Technical support online service provided.

4.Technical files service provided.

5.On-site training service provided.

6.Spare parts replacement and repair service provided.

About us

Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production. It was set up in 1998, and now is the main base in our country for manufacturing rubber roller special machine.

Power Company is a professional producer engaged in rubber roller manufacturing equipment, with a large production scale and strong technical force. The products we provide are: Rubber Roller Builder, Rubber Roller Grinding Machine, External Cylindrical Grinder, Emery Belt Precision Machine, Fully Automatic Measuring Instrument, Grinding Head and Fitting of Equipment. More than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. In 2000, our products passed the inspection by CCIB Quality Certification Center in accordance with ISO 9001 standards. By using our equipment, you will increase processing efficiency, and raise product quality. Also it can bring much economical benefit.

Power Company regards "customers first" as its principle and has been developing and producing satisfactory products for different types for customers. Janna Power Rubber Roller Equipment Co., Ltd sincerely welcomes friends at home and abroad to come here for business talks.

Our factory

Packing and Shipping

Our Exhibition

Our Customer

Contact Us

Please feel free to contact us for any question, we will reply within 24h.