- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fuerstar

-

Voltage:

-

380V, 50Hz

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

280 KG

-

Marketing Type:

-

Hot Product 2024

-

After-sales Service Provided:

-

Online Video Technical Support

Quick Details

-

Max Capacity:

-

500kg/batch

-

Production Capacity:

-

100-500kg/batch

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuerstar

-

Voltage:

-

380V, 50Hz

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

280 KG

-

Marketing Type:

-

Hot Product 2024

-

After-sales Service Provided:

-

Online Video Technical Support

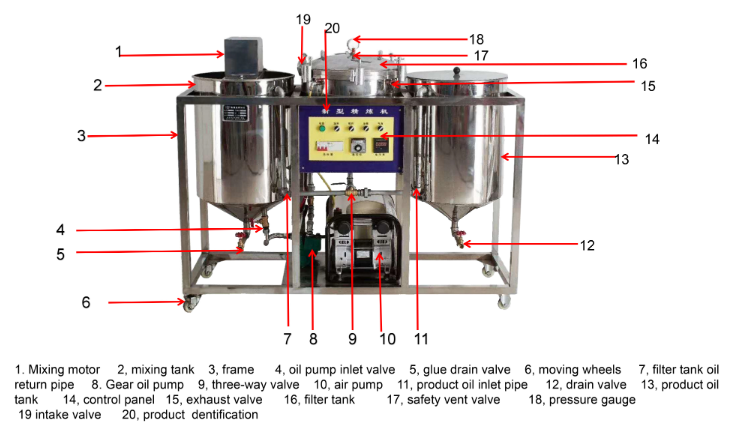

Product Overview

The complete set of oil refining units in the small oil mill has realized the integrated flow operation of dephosphorization,

degumming, deacidification, dehydration and decolorization, thus realizing the miniaturization of large-scale oil refining and the civil use of industrial oil refining. The complete set of refined oil equipment is accelerating to enter small and medium-sized oil plants, and is deeply favored by oil users. The refined oil can be directly filled and sold!

Product Description

Introduction of Cooking Oil Refining Process

Crude oil contains phospholipids, free fatty acids, pigments, peroxides, waxes and various mechanical impurities from by pressing or solvent extraction process . The presence of these impurities has adverse effects on the storage, consumption or processing of oils and fats. To remove these impurities, refining is required.

Refining mainly includes four steps: degumming, deacidification, bleaching and deodorization. For some oils, such as sunflower seeds, rice bran oil, corn germ oil, camellia oil, cottonseed (skimmed), palm oil, etc., they also need to be dewaxed or fractionated.

Degumming section

: The main component of colloidal impurities is phospholipids. The presence of phospholipids will make the oil dark and turbid. (Phospholipids will coke and become bitter when exposed to heat (280°C). Absorbing water will cause the oil to become rancid, affecting the quality and utilization of the oil. .) and affect the subsequent deacidification and bleaching processes, so degumming must be carried out first. When degumming, add dilute electrolyte, salt water or phosphoric acid (the amount of phosphoric acid used is about 0.05-0.2% of the crude oil.) Add The purpose of phosphoric acid is to convert non-hydrophilic phospholipids into hydrophilic phospholipids, which absorb water, swell and condense to form colloidal impurities (i.e. oil feet), which precipitate to the bottom of the refining tank, thereby achieving the purpose of degumming.

Deacidification section

: The presence of free fatty acids affects the taste and flavor of the oil. The storage time is short and the oil is prone to rancidity and deterioration, so deacidification is particularly important. Deacidification uses the principle of acid-base neutralization, adding alkali solution, and free fatty acids react with alkali solution to form soapstock (fatty acid salt (soap) and water). At the same time, soap stock also has a certain adsorption effect, which can absorb some pigments, sterols, solid impurities, etc., thereby achieving the purpose of deacidification. Soap stock is also a raw material for making soap. Can be sold directly.

Bleaching section

: The oil itself contains some pigments, such as chlorophyll, carotene, etc. The presence of pigments causes the oil to be darker, affecting the appearance. During the bleaching process, decolorants that can absorb pigments are used, such as activated clay, activated carbon, etc. Activated clay has strong adsorption capacity and is widely used in the bleaching of oil industry. When bleaching, heat the oil temperature to about 110 degrees, add white clay (the amount of white clay added is determined according to the customer's color requirements for the oil and the quality of the oil), and stir for 20-30 minutes. Then the oil is pumped into the leaf filter/frame plate filter for filtering and slag removal, and the white soil is filtered out to obtain light yellow and translucent oil.

Deodorization section

: The last important section is deodorization. After deodorization, it can reach the standard of first-class oil. Its function is to remove odor factors (remove aldehydes, ketones, hydrocarbons), low molecular fatty acids and other odor substances. The core equipment used is the deodorization tower (auxiliary equipment used in full continuous operation include continuous gas separator, oil-to-oil heat exchanger, fatty acid trap, bag filter, etc.).

Direct steam will continue to be introduced into the deodorization tower to bring the temperature to 220-260°C. Using the principle of steam distillation to remove odor factors and fatty acids from the oil, intermittent refining takes 3-4 hours, and continuous refining takes 60-90 minutes.

After the oil is deodorized, it is finely filtered, cooled to a safe storage temperature of about 40°C, and then stored in finished oil tanks.

In the refining process, some auxiliary systems are also required, such as thermal oil systems, steam generators (or steam boilers), vacuum systems, etc., through which the normal operation of the entire refining workshop is maintained.

Thermal oil system

: provides heat source for refining, especially the deodorization section, which requires the use of steam and thermal oil at the same time to reach the temperature required for deodorization.

Vacuum system

: In the bleaching and deodorization sections, which need to be carried out in a vacuum environment, series jet vacuum pumps will be used. Our company uses vacuum pumps from internationally renowned brands, which have high pumping efficiency, save steam and reduce energy consumption.

Hot Searches