- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Retain

-

Voltage:

-

220v/380v Customized

-

Dimension(L*W*H):

-

104*42*87

-

Power (kW):

-

1.5

-

Weight (T):

-

0.19

-

Name:

-

Mini Shredder Machine

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Crusher Shredder

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Usage:

-

Waste Plastic Cusher

-

Product name:

-

Shreddder Machine

-

Crushing material:

-

General Plastic Materials

-

Type:

-

Powerful Plastic Shredder

-

Marketing Type:

-

Product 2020

-

Raw material:

-

PET. PE. PVC

Quick Details

-

Max.Production Capacity (kg/h):

-

500

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

400 - 500 kg/h

-

Brand Name:

-

Retain

-

Voltage:

-

220v/380v Customized

-

Dimension(L*W*H):

-

104*42*87

-

Power (kW):

-

1.5

-

Weight (T):

-

0.19

-

Name:

-

Mini Shredder Machine

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Crusher Shredder

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Usage:

-

Waste Plastic Cusher

-

Product name:

-

Shreddder Machine

-

Crushing material:

-

General Plastic Materials

-

Type:

-

Powerful Plastic Shredder

-

Marketing Type:

-

Product 2020

-

Raw material:

-

PET. PE. PVC

More than 20 years of

Professional E

xperience !

Specialized in

the production of Plastic Crusher , Hopper Dryer, Loader,Vertical Mixer,Industry Chiller,Conveyor Belt and so on-----

Plastic Auxiliary Equipment Factory

Production Photos

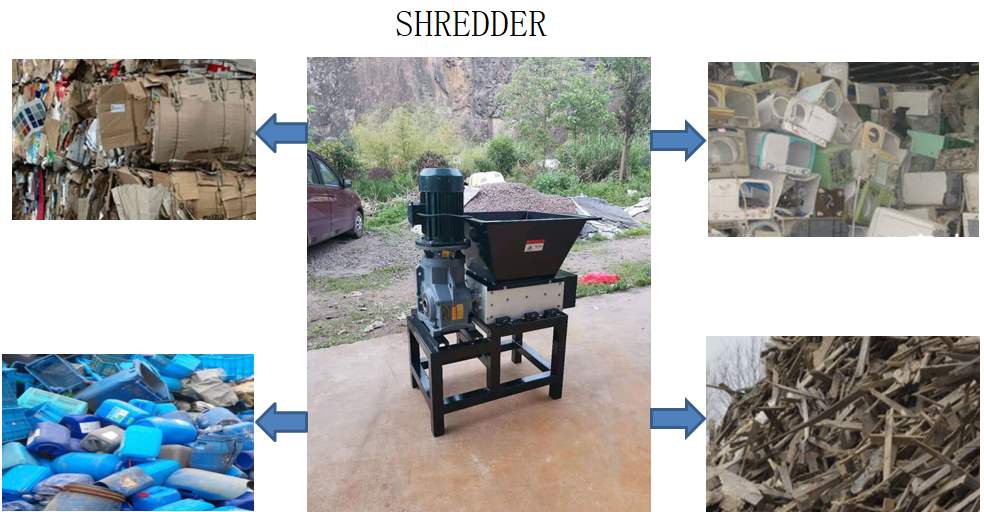

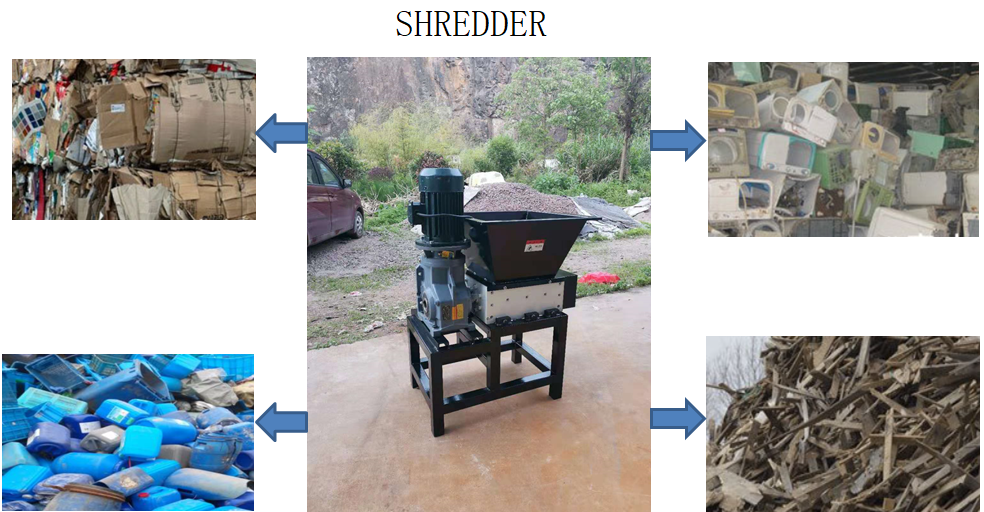

Shredder

Product advantages and features:

1. The rotor on the knife seat and blade can be detachable, easy to clean, maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° after wear and continue to use;

3. The main shaft is driven by the gear reduction box, running smoothly, low noise, large torque;

4, Using PLC program control system, automatically positive and negative rotation, so that the machine runs stably;

5, The box adopts welding, after welding tempering treatment, eliminate welding stress;

6, The moving tool installation position adopts machining center precision machining, to ensure that the clearance of each moving tool and fixed tool is the same;

7, The tool holder adopts embedded mode with high strength screw connected to the tool shaft, can prevent the welding type in the long-term vibration after the phenomenon of knife drop.

8. Convenient transportation after shredding, can reduce transportation costs, increase transportation efficiency, convenient secondary processing.

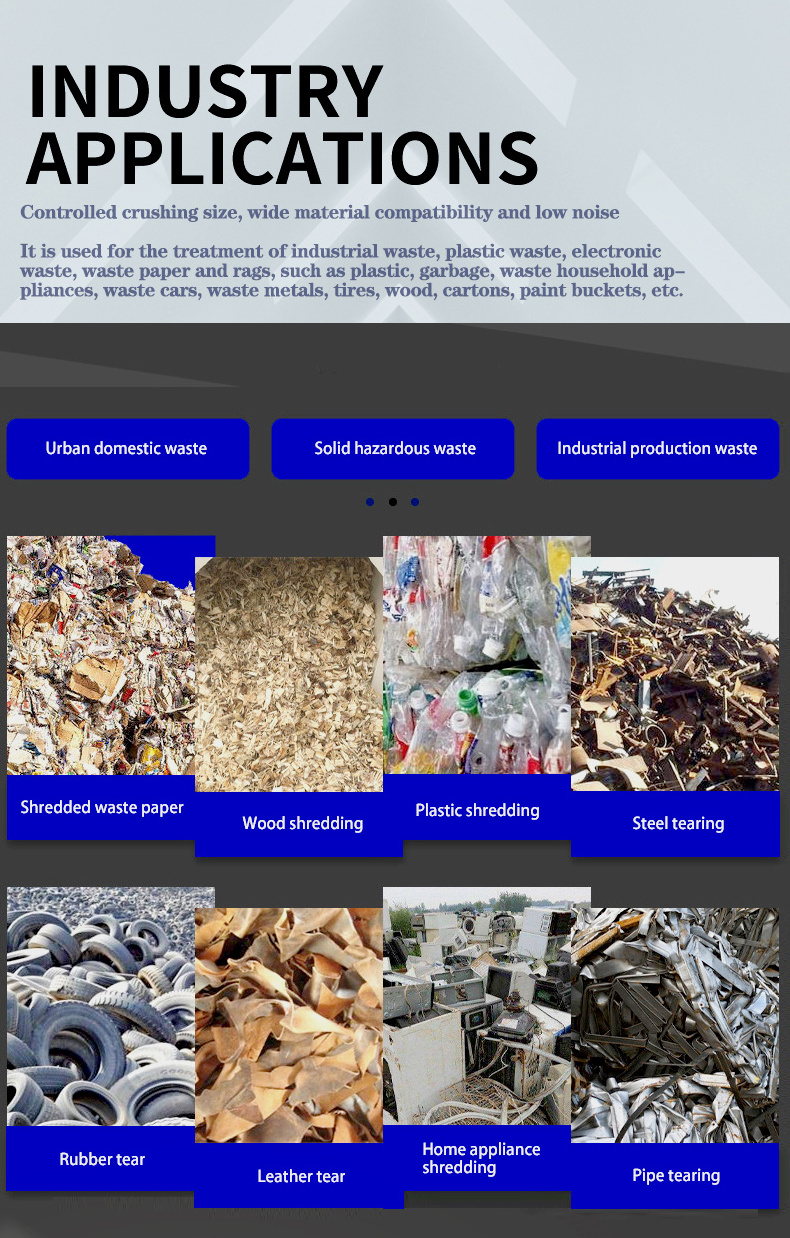

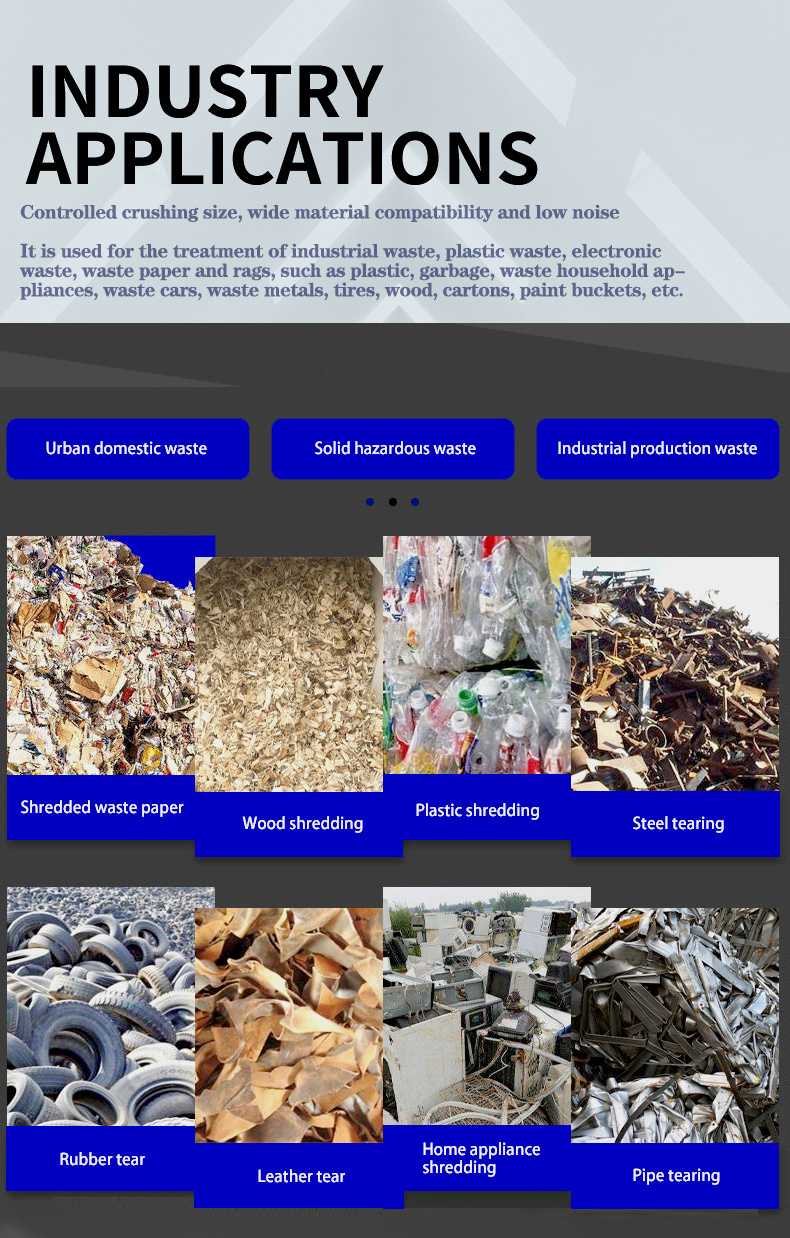

Shredding machine crushing range:

Shredding machine crushing range:

Industrial waste/Household waste - Household waste, wood waste, kitchen waste, Kitchen waste, Industrial waste, factory waste, municipal sludge, glass fiber reinforced plastic, pulp residue cloth; Biomass - branches, leaves, straw, corn cob, wheat stalk, bark, banana tree, straw, garden waste; Recycling waste - paper, waste plastics, plastic bottles, chemical barrels, aluminum materials; Destruction of product documents - computer hard drives, documents, unqualified products, expired drugs, plastic parts, waste disposal - medical waste, radioactive materials, organic waste, hazardous solid waste; - Paint cans, paint cans, tin cans,

Production Details

BLADES

Shredding machine blade after forging, annealing heat treatment, tempering heat preservation in line cutting fine grinding.

PURE COPPER CORE MOTOR

The strong power of all copper wire composed of high efficiency strong motor, failure rate is small, fast heat dissipation.

HIGH HARDNESS

High temperature quenching, long service time, quality assurance

GEARBOX

Steel plate welding, high precision, good contact, low noise, with long service life.

STABLE FRAME

High strength shredder material , better stabe

TRANSMISSION PARTS

Transmission parts with coupling link, reduce vibration, protect the spindle and reducer, do not damage the force.

THICKENED PLATE

Thickened plate welding, stainless steel material, durable, not easy. Rust, simple and beautiful appearance.

Production Specification

|

Shredder Specification

|

|

|

|

|

|

|

|

|||||||

|

Model

|

|

RT200-1.5

|

RT200-5.5

|

RT300-3

|

RT300-4

|

RT400

|

RT600

|

|||||||

|

Reducer

|

|

R67

|

K87

|

K87

|

K87

|

K87

|

K87

|

|||||||

|

Power

|

|

1.5KW

|

5.5KW

|

3KW

|

4KW

|

3-7.5KW

|

3-7.5KW

|

|||||||

|

Torque

|

|

600N.M

|

2590N.M

|

1510N.M

|

1510N.M

|

1500-3500N.M

|

1500-3500N.M

|

|||||||

|

Weight

|

|

190KG

|

310KG

|

300KG

|

300KG

|

The weight varies according to the configuration

|

|

|||||||

|

Measurement

|

|

104*42*87

|

83*42*127

|

80*42*127

|

80*42*127

|

103*42*127

|

124*42*127

|

|||||||

|

Power cord length

|

|

60CM

|

60CM

|

60CM

|

60CM

|

60CM

|

60CM

|

|||||||

|

Number of blades

|

|

20

|

20

|

30

|

30

|

40

|

60

|

|||||||

|

blade thickness

|

|

10MM

|

10MM

|

10MM

|

10MM

|

10MM

|

10MM

|

|||||||

|

Blade size

|

|

∅150

|

∅150

|

∅150

|

∅150

|

∅150

|

∅150

|

|||||||

|

Blade material

|

|

9CRSI

|

9CRSI

|

9CRSI

|

9CRSI

|

9CRSI

|

9CRSI

|

|||||||

|

Remark: Color, size, voltage, customer requirements can be customized.

|

|

|

|

|

|

|

|

|||||||

Zaozhuang Retain Manufacturing&International Trading Co.,Ltd

Introduction

Our company is a leading manufacturer in China with more than 20 years of professional experience.Specializing in Plastic Auxiliary Machinery, Refrigeration and Cooling Equipment, Agricultural Equipment, Take-up Machine and Shears,Bends ,Rolling Machines. The company has set up three factories in Guangzhou, Zhejiang and Jiangsu.We have a professional R & D team and after-sales team, which can fully meet the requirements of different customers, and we will immediately solve the customer feedback problems. our products exported to United States,Italy,Russia,Japan, European countries and are widely praised by global clients

.

FAQ

Are you manufacture?

Sure, We are one of leading manufacturers with 20 years of professional experience in China

Do you have Stock productions to sell?

Yes,it is .But we also offer OEM/ODM service. Please send us your request if you are interested.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20years production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process.

Hot Searches