- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2.6*1.0*1.85m

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v 50HZ Three

-

Power:

-

180kw, 150kw

-

Machine name:

-

Breakfast cereals corn flakes making Machine

-

tasty mouth:

-

decilious

-

materials:

-

Stainless steel

-

craft:

-

extrusion/automatic

-

energy:

-

electricity/diesel/gas

-

shapes:

-

such as ball,sticks,flower,nails,star and so on

-

operate workers:

-

2-3 workers

-

capacity:

-

200-250kg/h

-

Web:

-

www.fldmachine.com

Quick Details

-

Machinery Capacity:

-

100-250kg/h

-

Brand Name:

-

FLD

-

Year:

-

2021

-

Dimension(L*W*H):

-

2.6*1.0*1.85m

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v 50HZ Three

-

Power:

-

180kw, 150kw

-

Machine name:

-

Breakfast cereals corn flakes making Machine

-

tasty mouth:

-

decilious

-

materials:

-

Stainless steel

-

craft:

-

extrusion/automatic

-

energy:

-

electricity/diesel/gas

-

shapes:

-

such as ball,sticks,flower,nails,star and so on

-

operate workers:

-

2-3 workers

-

capacity:

-

200-250kg/h

-

Web:

-

www.fldmachine.com

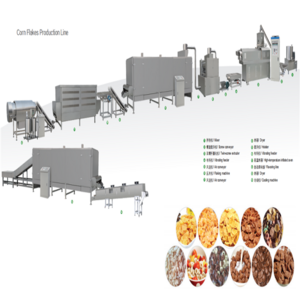

FLD Factroy sell corn flakes making machine automatic breakfast cereals production line:

Corn flakes is a kind of crisp food, used grain flour as the basic raw material. By the processing line it is processed to flakes instant food which is pressed by particle. The outstanding feature is that it is rich in composite carbon compounds and dietary fiber. At the same time, corn flakes can not only strengthen much trace element, such as vitamins and minerals,but also add cocoa and sugar,such as honey,maltose, etc. After adding into coffee,milk,yogurt,or functional drinks, we

can directly eat it. Children can also eat it as sweet and brittle leisure snack food.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

1.Flour mixer : to mix various raw materil evenly.

2.Screw conveyor : to convey raw material to extrude

3.Twin/Double screw extruder :to extruder and cook the raw material into different shapes breakfast cereal

4.Water injector: to inject water on the producing process.

5.Vibrating cooler: to spread the products and cool it quickly.

6.Air conveyor: to convey the food to the next machine

7.Flakes presser: to press the particles into thin flakes (its size of flakes can be adjusted)

8.Higher vibrating cooler: to spread the flakes and sancks food and cool it quickly.

9.Belt drying oven: to dry snacks food by circulating belt.

10.Belt conveyor: to elevate the snacks food to the next machine

11.High temperature toaster: to use hot air to dry the snacks food.

12.Flavoring machine: to spray flour ,sugar oil and other seansons on the food to get decilious food.

13.Extending drying oven: to dry the corn flakes after it being coated sugar.

14.Cooling conveyor: to cool food.

| Model | SLG65-III | SLG70-III | SLG85-III |

| Install Power | 76KW | 95kw | 178kw |

| Power Consumption | 54KW | 66kw | 125kw |

| Capacity | 80-120KG/H | 150-200kg/h | 280-350kg/h |

| Dimension | 40×3×2.5m | 45×3×4m | 48.5×5×4m |

6.Main equipment of Breakfast cereals corn flakes making Machine:

|

Mixer

To mix the raw materials evenly, fast speed, no leakage.

Type: Vertical and horizontal type Motor: 3kw, 4kw, 7.5kw etc. Material: stainless steel, carbon steel |

|

Extruder

To extrude the raw materials and make them to the required shape and size of the puff snacks food by mould.

Model: SLG65, 70, 85

Capacity: 100kg/h to 500kg/h

Material: Screw materials 38CrMoAlstainless steel, carbon steel

|

|

|

Dryer

Baking puff snacks food.

Type: electrical, steam, gas fired, diesel fired heating type

Model: KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 Capacity: 100kg/h to 10 ton/h Material: stainless steel, carbon steel |

|

|

Flavoring roller

To mix the oil and flavors on the surface of the snacks food.

Type: single and double flavoring drum Motor: 0.75kw Capacity: 100kg/h to 500 kg/h Material: stainless steel |

7.Breakfast cereals corn flakes making Machine Main Features:

1. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

3. The gearbox has automatic lubrication function, with extends gear life.

4. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

5. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

6. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers'

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.