- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

10X3X3

-

Weight (T):

-

200 T

-

Power (kW):

-

90

-

Certification:

-

CE ISO

-

Product name:

-

Gas Fired Reheating Furnace

-

Capacity:

-

10-50T

-

Heating fuel:

-

natural gas

-

heating way:

-

by both sides

-

Function:

-

heat steel billets

-

natural gas consumption:

-

36CMB/T steel

-

Max temperature:

-

1200.C

-

Suitable Metal:

-

carbon steel

-

Color:

-

gray or other

-

Working theory:

-

save energy model

Quick Details

-

Place of Origin:

-

Hainan, China

-

Brand Name:

-

HengYuan

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

10X3X3

-

Weight (T):

-

200 T

-

Power (kW):

-

90

-

Certification:

-

CE ISO

-

Product name:

-

Gas Fired Reheating Furnace

-

Capacity:

-

10-50T

-

Heating fuel:

-

natural gas

-

heating way:

-

by both sides

-

Function:

-

heat steel billets

-

natural gas consumption:

-

36CMB/T steel

-

Max temperature:

-

1200.C

-

Suitable Metal:

-

carbon steel

-

Color:

-

gray or other

-

Working theory:

-

save energy model

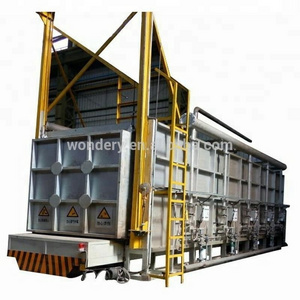

Gas Fired Reheating Furnace

The following is main structure of the Gas Fired Reheating Furnace

Our steel billets reheating furnace is mainly for reheating the steel billets in steel factory

it can heat the steel billets size as 100x100x3000mm, 120x120x3000mm, 150x150x4500mm steel billets

|

REHEATING FURNACE 15t/h (Regenerative system) |

|||

|

1 |

Machine Spare part |

set |

1 |

|

2 |

Metal Material |

set |

1 |

|

3 |

Refractory |

set |

1 |

|

4 |

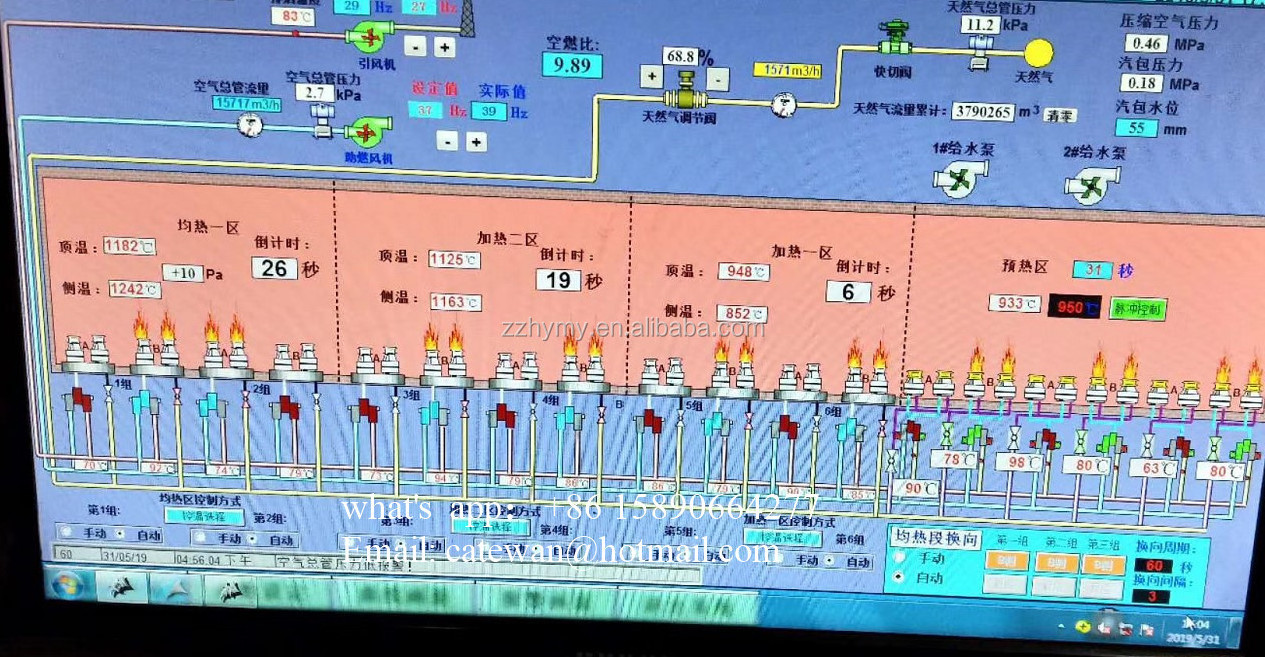

PLC Control cabinet |

set |

1 |

|

5 |

Other Material |

set |

1 |

|

6 |

Design and Construction |

set |

1 |

|

7 |

Steel Billet Pusher+Extractor+roller table for Reheating Furnace |

set |

1 |

|

8 |

Installation and Training |

|

|

We are using two sides heating , it will inprove the heating effeciency, and we reduce the smoke removing temperature, So our natural gas consumption of Gas Fired Reheating Furnace is only 36CMB per ton steel , it is save-energy a lot

For steel billets reheating furnace PLC control, we are using Automatic way, it can changing the burning direction and control the burning temperature automatically,

The following is one design example of our Gas Fired Reheating Furnace

1.Design Conditions

(1) use of reheating furnace: pre-heating of rolling steel billets .

(2)reheating furnace model: steel push heating furnace

(3)burning mode: air single regenerative type

(4)heating mode: one--side heating

(5)fuel type: natural gas ( calorific value 8600Kcal/ Nm 3 )

(6)heating temperature 1150℃ (according to the requirement of rolling)

(7)steel type of heating: carbon-steel, optimal carbon-steel, alloy steel

(8)size of steel billets: 120×120×3000mm

(9)method of inputting and outputting of the steel billets: end in and side out the steel billets

(10)slide-way of pulsion: Zirconium corundum convex groove composite brick

(11)Rated heating capacity: 10t/h (steel billets)

(12)difference in temperature of outputting the steel billets: ≤30℃

(13)effective size: length9000mm × width3480mm

(14)standard altitude of steel tapping: will decide

(15)reversing way: two-position three-way valve dispersion commutation

(16)maximum unit consumption: 36Nm³/ t steel

(17)burning sector: second stage

(18)natural gas switching mode: electromagnetic valve

(19)control mode: fully automatic / semi-automatic / manual switchable control

our reheating furnace also hot sold in different countries, such as in Pakistan, Indonesia,

Nigerial, Phillipine and so on

Welcome to contact with us, if you are interested in our Steel billets reheating furnace