1.Using unique design,avoid the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the

pollution.

2.Washing pump is made of stainless steel.

3. By high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

4. Bottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion resistant bearing without maintenance.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

nancheng machinery

-

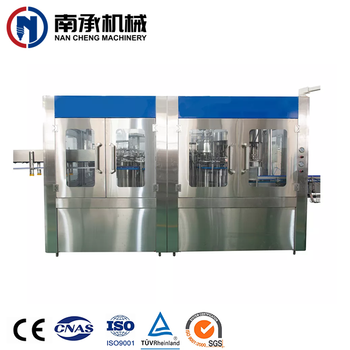

Dimension(L*W*H):

-

3880*2800*2500mm

-

Weight:

-

7500 KG

-

Product name:

-

Soft Drink Filling Machine

-

Function:

-

Bottle Washing Filling Capping

-

Filling material:

-

water, Carbonated soft drink,CSD,juice,etc

-

Bottle type:

-

pet/plastic bottle

-

Material:

-

Stainless Steel 304/316

-

Filling type:

-

High Precision Filling Level

-

Capacity:

-

3000-24000bph

-

Filling volume:

-

200 -- 2000ML

-

Control:

-

PLC+ Touch Screen

-

Advantage:

-

20 Years Experiences

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

nancheng machinery

-

Dimension(L*W*H):

-

3880*2800*2500mm

-

Weight:

-

7500 KG

-

Product name:

-

Soft Drink Filling Machine

-

Function:

-

Bottle Washing Filling Capping

-

Filling material:

-

water, Carbonated soft drink,CSD,juice,etc

-

Bottle type:

-

pet/plastic bottle

-

Material:

-

Stainless Steel 304/316

-

Filling type:

-

High Precision Filling Level

-

Capacity:

-

3000-24000bph

-

Filling volume:

-

200 -- 2000ML

-

Control:

-

PLC+ Touch Screen

-

Advantage:

-

20 Years Experiences

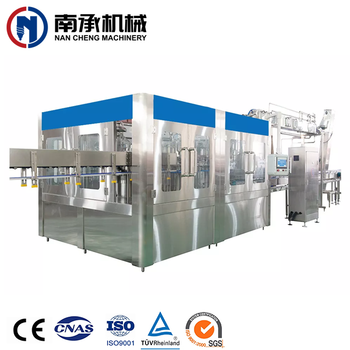

Carbonated Soft Drinks Lines.

Success in Carbonated Soft Drinks (CSD) beverage production requires focus on flexibility and overall efficiency, with

cost-effective resource management and branding opportunities that deliver optimal results across your supply chain. Our unmatched expertise and technical knowledge of PET packaging helps you achieve more.

With over 340 years of experience in designing and implementing customised complete PET line solutions for carbonated soft drinks,we can help you expand your line's production capabilities. Over the years, we have significantly reduced the weight of CSD bottles while retaining bottle resistance and expanding design opportunities.

cost-effective resource management and branding opportunities that deliver optimal results across your supply chain. Our unmatched expertise and technical knowledge of PET packaging helps you achieve more.

With over 340 years of experience in designing and implementing customised complete PET line solutions for carbonated soft drinks,we can help you expand your line's production capabilities. Over the years, we have significantly reduced the weight of CSD bottles while retaining bottle resistance and expanding design opportunities.

Details Images

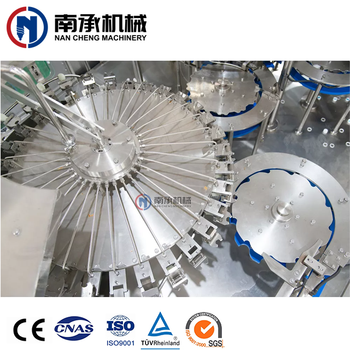

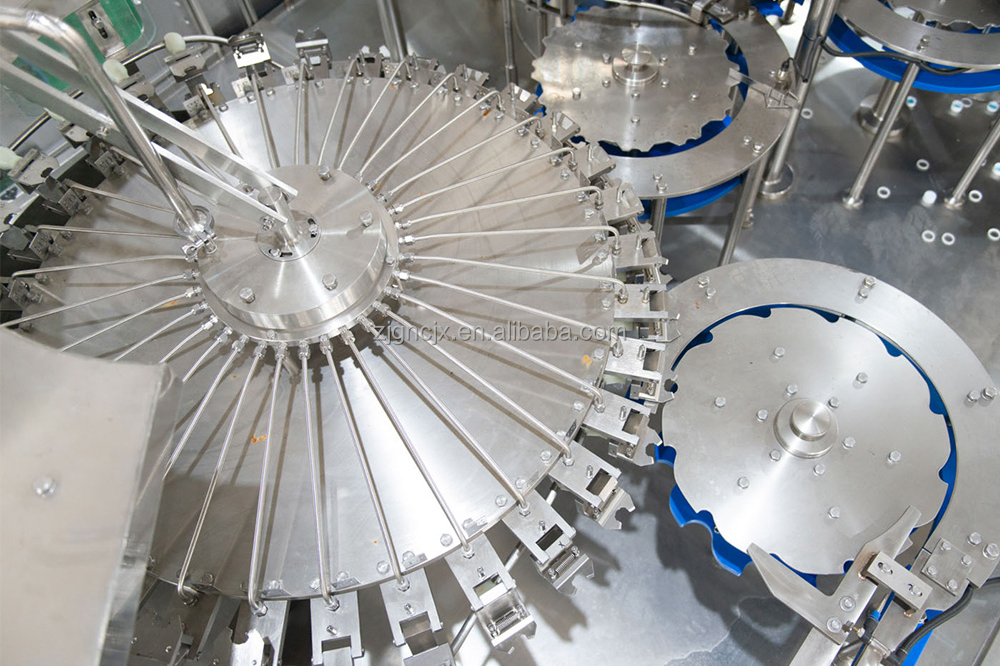

Washing heads

Filling heads

1.Filling method for gravity filling.

2.Filling valve manufactured SUS 304/316L.

3.High precision, high speed liquid filling.

4.Filling move by the rack drive system through gear transmission.

5.Hydraulic cylinder controlled by a float liquid level.

6.Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

2.Filling valve manufactured SUS 304/316L.

3.High precision, high speed liquid filling.

4.Filling move by the rack drive system through gear transmission.

5.Hydraulic cylinder controlled by a float liquid level.

6.Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

Capping heads

1.Automatic check,no bottle no capping.

2.Capping heads in stainless steel 304/316L.

3.Capping heads stop working when lack of bottle.

4.Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5.High efficiency centrifugal principle.

2.Capping heads in stainless steel 304/316L.

3.Capping heads stop working when lack of bottle.

4.Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5.High efficiency centrifugal principle.

Technical Parameters

|

PROJECT

|

CARBONATED DRINK FILLING MACHINE

|

|

|

|

|

|

|||||

|

Model

|

12-12-5

|

18-18-6

|

24-24-8

|

32-32-10

|

40-40-12

|

50-50-15

|

|||||

|

Capacity (BPH)

|

2000-3000

|

3000-5000

|

5000-7000

|

7000-10000

|

10000-15000

|

16000-20000

|

|||||

|

Applicable bottle

|

φ=50-115 H=160-330 (200ML TO 2000ML) plastic screw cup or crown cap

|

|

|

|

|

|

|||||

|

Air press(Mpa)

|

≤0.4

|

|

|

|

|

|

|||||

|

Power supply

|

4.4 KW

|

5.2 KW

|

6.2 KW

|

6.2 KW

|

7.5 KW

|

11 KW

|

|||||

|

Overall dimension

|

2250×1650×2250

|

2600×1965×2250

|

2980×2200×2250

|

3880×2200×2250

|

4000×2250×2500

|

5500×3500×2500

|

|||||

|

Weight (KG)

|

2500

|

3500

|

4500

|

6000

|

7200

|

10000

|

|||||

Production Process

1-Water Treatment.

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

Benfits.

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

2-

Blow Molding Machine

1 / Blower : Industry-leading blower performance with patented control and self-regulation systems for repeatable and consistently high bottle quality

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

3-Labeling Machine.

Boasting four carousel sizes, up to three labelling stations and 24 configurations, can generate outputs of up to 72,000 containers per hour, when standalone, at an efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

4 -Packing Machine.

Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale, so it needs to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes. Whether you choose shrink-printed film, nested packs or wraparound cartons, King Machine packers gently feed bottles to ensure durable and cost-effective packs.

Benfits.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

Benfits.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

Top Filling Solution

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

NanCheng Service

Bottle Design Drawing

Whole Production Line Layout Design Drawing

Turn Key Project

7*24 Hours Service

Hot Searches