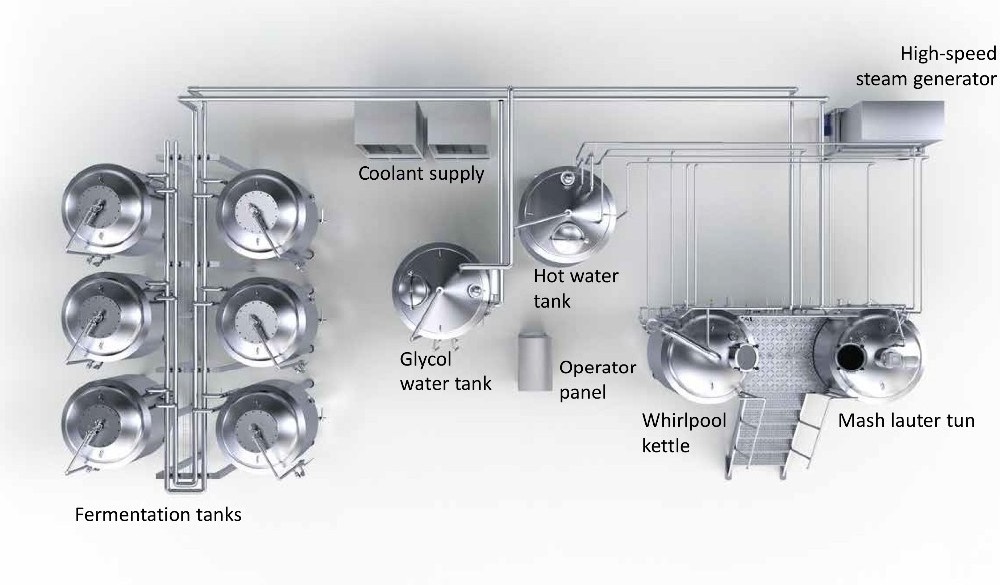

* Brew kettle & Whirlpool tank

* Hot water Tank

* Operating platform

* Plate heat exchanger

* Temperature measurement oxygenate machine

* Lees out harrow etc

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

As capacity

-

Dimension(L*W*H):

-

As capacity

-

Weight:

-

4800 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

Automatic beer making machine to make craft beer with capacity 100l

-

Thickness:

-

External 2mm; Internal 3mm

-

Welding:

-

100% TIG

-

Control System:

-

PID/PLC

-

Process:

-

Acid washing and Passivation

-

Application:

-

Beer Packaging Factory

-

Function:

-

Brewing Beer

-

Cleaning method:

-

Acid washing and Passivation

-

Heating:

-

Electric/Steam/Direct fired

-

Keywords:

-

machine make beer

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

King Machine

-

Voltage:

-

As local demands

-

Power:

-

As capacity

-

Dimension(L*W*H):

-

As capacity

-

Weight:

-

4800 KG

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

Automatic beer making machine to make craft beer with capacity 100l

-

Thickness:

-

External 2mm; Internal 3mm

-

Welding:

-

100% TIG

-

Control System:

-

PID/PLC

-

Process:

-

Acid washing and Passivation

-

Application:

-

Beer Packaging Factory

-

Function:

-

Brewing Beer

-

Cleaning method:

-

Acid washing and Passivation

-

Heating:

-

Electric/Steam/Direct fired

-

Keywords:

-

machine make beer

Automatic beer making machine to make craft beer with capacity 100l

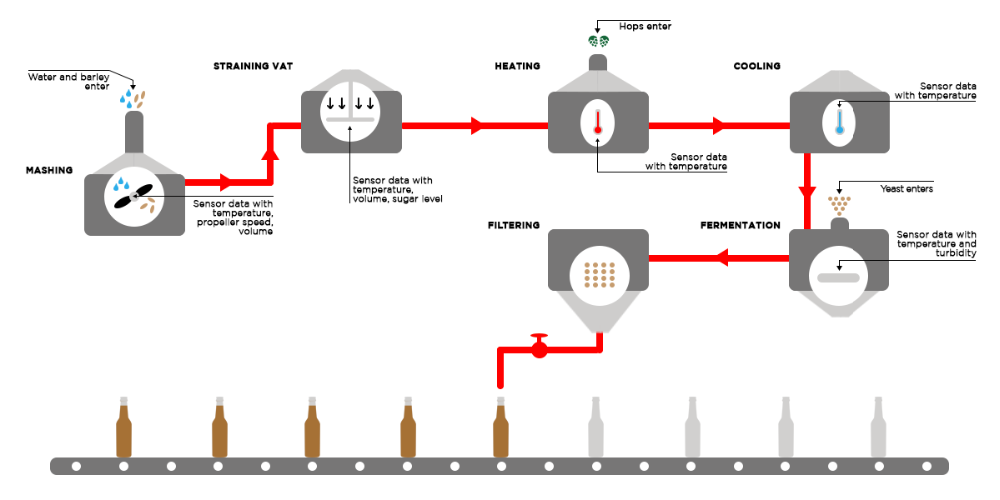

Beer Brewery equipment is used for lab ,pub,bar,hotel,restaurant,industry brewery etc. from 50L to 30000L per day. Brewing process inlcude Milling, mashing, lauterung, boiling, whirlpool, wort chilling, fermentation&maturing, cooling, temperature controlling, cleaning, filling etc..So complete beer brewing equipment including brewhouse, fermentation tanks, bright beer tank, glycol system, controlling system, beer filling machine ect.We can provide the design solution from drawing until after installation.

Beer Brewing Equipment.

1 / Brewing block for manual operation < 5hl / 10hl / 17hl >.

2 / Skid solution for automatic operation < 25hl - 40hl >.

1.Crush system.

* Malt Mill

* Conveyor Filler

2.Heating System.

* Rated pressure(MPa)

* Saturated steam temperature(℃)

* Resin tank

* Regenerated salt box

5. Cooling System.

* Ice water tank

* Refrigerating unit

* Ice water pump

* Pipelines

* Valves and so on.

6. Cleaning System.

* Alkali tank

* Aseptic water tank

* Cleaning pump and so on.

7.Control System.

* Display degree together

* Siemens Brand

* Control the power of the brewhouse, the variable frequency of the wort pump

* Control the temperature and the pump of the hot water tank

* Control the temperature & pressure of the fermetner and bright beer tanks .etc

8.Beer Bottle Filling System.

* Glass Bottle Washing Filling Capping Monoblock Filling Line

3.Mash System.

Technology – Mash System.

Two-roller grist mill.

− Milling capacity of 500 kg/h with manual malt feed and grist removal

− Easy milling gap adjustment for optimal grist results

Mashing.

− Shell heating for the mashing process

− Pillow plate technology for low thermal impact

Mash and lauter tun.

− Well-proven false bottom from the large tun construction

− Pitot tube for manual lautering control

− Shell sight glass for monitoring of the first wort intake

Wort boiling.

− Shell and bottom heating for optimum heating rates

− Intensive evaporation of undesired flavourings with the Stromboli ascending pipe

− Content can be read off on the scaled shell sight glass

− Optional vapour rejection or vapour condenser

4. Fermentation System.

* Fermentation tank

* Ice water electromagnetic valve

* Beer tube

* Refrigerant piping

* Bright beer tank

* Safety valve

* Temperature probe

* Ralves and so on.

* Yeast storage tank

* Pressure gauge

* Temperature transmitter shell

Technology – Fermenting cellar.

Fermentation tanks

− Net capacity of 5, 10, 17 or 35 hl

− Shell and cone cooling

− Bunging apparatus, temperature display and pressure display all included in the scope of supply

− Safety measures against vacuum and overpressure in accordance with German pressure vessel regulations

Technology – Supply units.

Hot water storage

− Water tank with shell heating

− With temperature display and full signal

High-speed steam generator

− 50 kg/h saturated steam per unit

− Electrical operation or gas operation

− One unit for a brew size of 5 hl

− Two units for a brew size of 10 hl

Coolant supply

− Glycol water tank with shell cooling

− One cooling unit of 14 kW* for a brew size of 5 hl

− Two cooling units of each 8.5 kW* for a brew size of 10 hl

CIP system

− Optional 1-tank or 2-tank line available

− Standard: lost CIP with vessel feed

* Based on the use of local suppliers; deviations possible in terms of number and output

Operator control concept.

− Manual composition and milling of the malt batches

− Mashing in is performed via the manhole, the main mashing water is supplied in a tempered condition

− Saved recipes for temperature management and rest duration with automatic process sequence

− The lautering process and the required pump performance are controlled via the operator panel.

− The lautering pressure is displayed as the control variable via a pitot tube with a sight glass in the wort line.

− Manual removal of the spent grains

− Recipes for boiling with control of the parameters 'time'and 'temperature'

− Manual dosing of hops via the manhole

Operator control concept.

− The wort is casted out after the end of the whirlpool rest time.

− Manual control of the pitching temperature via the glycol water amount

− Manual check of wort aeration downstream of the cooler

− Addition of yeast in the fermentation tanks

− Temperature control during fermentation: Recipes can be saved in the control system

− Manual adjustment of CO2 saturation at the bunging apparatus

− Cleaning of vessels and tanks via mobile CIP pump with hose connections to the spray head

Benefits to you.

Compact dimensions

− Design is carefully tailored to applications with limited space

− Plant is shipped in just a few standard containers

Ease of operation

− Recipe-based programme sequences assist with the manual work steps

− Sight glasses and field instruments integrated in the plant for monitoring of the brewing processes

Use of components from large-scale plant construction

− Cost-effective brewing technology with attractive investment costs

Want to know more message , contact us with out hesitate ! Inquiry us now !

Zhangjiagang King Machine Co.,Ltd

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

King Machine Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

King Machine Cetificates and Patents.

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments:

ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration, etc.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.