- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

XINGANG

-

Dimensions(L*W*H):

-

2700x1600x1600mm

-

Weight:

-

2100 KG

-

Certification:

-

ISO

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

380V

-

Place of Origin:

-

China

-

Brand Name:

-

XINGANG

-

Dimensions(L*W*H):

-

2700x1600x1600mm

-

Weight:

-

2100 KG

-

Certification:

-

ISO

Product Description

XG-520/620/820 Automatic Roll to Roll Silk Screen Printing Machine

This machine is widely used in PET,PYCPC,membrane switches.flexibleprinted circuit board, too solar battery to warm film, electric film, transfer film, paperflowers, mobile phone shell buttons (lMD workers art printing), 3M glue, lasertrademark,anti-counterfeiting scratch cards, stickers and labels roll material Thematerials and specialink, glue, a screen printing.

1

、

The machine printed full touch screen operation, fully automatic electric eyetracking, computer PLC control system,printing speed, high precision overprint:

2

、

Servo motor drive printing and pull materials, printing. back to mkexico andthe distance and speed can be with ltaly adjustment;

3

、

Plane platen surface anti-static treatment, which greatly reduces the platenElectrostatic adsorption force on the printed material. Thus effectively reducingthe strain ofthe materialon the back:

4

、

Photoelectric sensor switch control discharge and receipts, to avoid scratchingthe surface of printed materials , which greatly lmproves the printing quality;

5

、

The machine is equipped with a dust removal roller, automatically removedust from the material:

6

、

The machine is equipped with automatic off-grid function. When printingcolor in large area and glue. Prevent sticking network;

7

、

The machine uses a three-stage suction device, according to the requirementsof the printed material, strong winds.weak wind, close the regulator:

8

、

Humane printed warning device, material printing is completed, arriveprinting set the value early warning and exception dengjun will automaticallyshut down;

9

、

Ovens standard insulation layer, surrounded by district heating, digitalthermostat controlled separately temperature is more uniform and stable;

10、The photoelectric sensor switch combined with variable frequency motorspeed control receipts,ensure the oven rewinding speed printing speed:the oven installed anti-inverted pull folder feeder. convenient bakingmaterials handling:

11、The feeder can be required the installation of automatic tear protectivefilm device, feeding with a complete tear film;

12、The oven may need to install the device automatically fit: fit on filmdouble-sidedadhesive.release paper.the protective film:

13、Tthe machine can be connected to the UV dryer, glazing cutting machineslitting machinecutter machine:

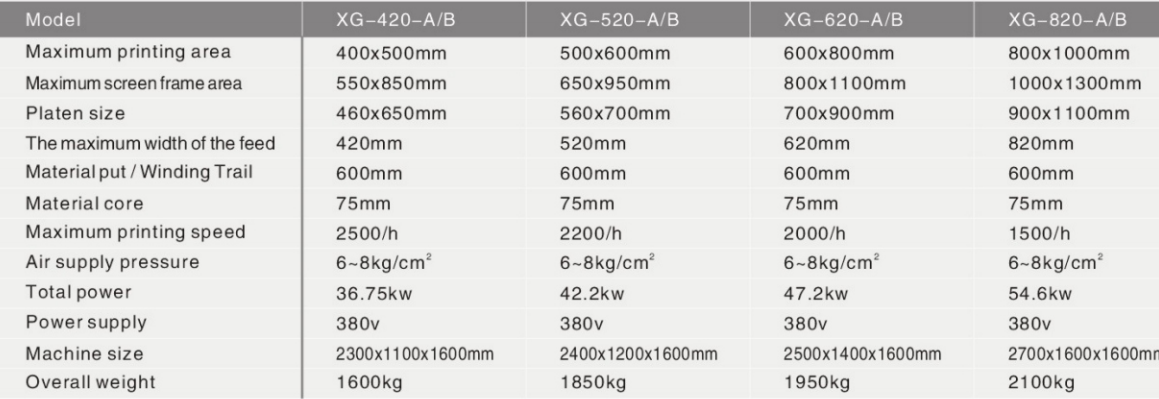

Specification

Packing & Delivery

wooden case & vacuum plastic package

Hot Searches