- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

EPB5F

-

Place of Origin:

-

Zhejiang, China

-

Product Name:

-

EPB5F Self-lubricating Plastic Bearing

-

Material:

-

EPB5 Engineering Plastic

-

Lubrication:

-

Self-lubricating

-

Customize:

-

Yes

-

Certification:

-

ROHS

-

sample:

-

sample fee

-

Brand:

-

CSB

-

Weight:

-

0.06g

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Construction works , Energy & Mining, Other

-

Precision Rating:

-

E10

-

Brand Name:

-

CSB

-

Model Number:

-

EPB5F

-

Place of Origin:

-

Zhejiang, China

-

Product Name:

-

EPB5F Self-lubricating Plastic Bearing

-

Material:

-

EPB5 Engineering Plastic

-

Lubrication:

-

Self-lubricating

-

Customize:

-

Yes

-

Certification:

-

ROHS

-

sample:

-

sample fee

-

Brand:

-

CSB

-

Weight:

-

0.06g

PRODUCT DESCRIPTION

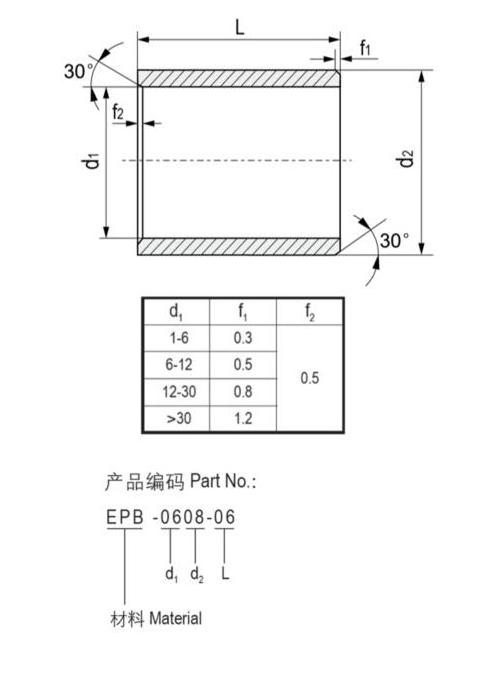

EPB Plastic Plain Bearings

● Self-lubricated material for high temperature up to 250 ℃. With its high chemical resistance feature, it coul be used inside most common chemical liquids. It is a high load material for the applications of high temperature and critical chemical environments

● Continuous working temperature: -100℃/+250℃

● Suitable for high load operation

● High load capacity at higher temperature

● Good chemical resistance

● Low water absorption

● High pressure resistance

● Continuous working temperature: -100℃/+250℃

● Suitable for high load operation

● High load capacity at higher temperature

● Good chemical resistance

● Low water absorption

● High pressure resistance

PRODUCT SPECIFICATIONS

|

Material Properties

|

Standard

|

Unit

|

CSB-EPB5F

|

|||

|

General Properties

|

|

|

|

|||

|

Color

|

-

|

-

|

Black

|

|||

|

Density

|

ISO1183

|

g/cm3

|

1.44

|

|||

|

Max. moisture absorption,50%RH

|

ISO62

|

%

|

0.1

|

|||

|

Max. water absorption

|

ISO62

|

%

|

0.5

|

|||

|

Coefficient of sliding friction(steel)

|

ITS025

|

µ

|

0.09-0.25

|

|||

|

Max. PV value

|

ITS026

|

N/mm

2

×m/s

|

1.40

|

|||

|

Mechanical Properties

|

|

|

|

|||

|

Flexural modulus

|

ISO178

|

MPa

|

4800

|

|||

|

Flexural strength

|

ISO178

|

MPa

|

165

|

|||

|

Max. static load

|

ITS027

|

MPa

|

110

|

|||

|

Max. dynamic load

|

ITS028

|

MPa

|

61

|

|||

|

Shore hardness

|

ISO868

|

D

|

82

|

|||

|

Physical and thermal properties

|

|

|

|

|||

|

Long-term application temperature

|

ITS029

|

℃

|

+250

|

|||

|

Short-term application temperature

|

ITS029

|

℃

|

+315

|

|||

|

Lowest application temperature

|

ITS029

|

℃

|

-100

|

|||

|

Thermal conductivity

|

ISO22007

|

W/m/K

|

0.55

|

|||

|

Coefficient of thermal expansion

|

ISO11359

|

K

-1

×10

-5

|

6

|

|||

|

Flammability

|

UL94

|

Class

|

V0

|

|||

|

Electrical properties

|

|

|

|

|||

|

Volume resistance

|

IEC60093

|

Ω·cm

|

>108

|

|||

|

Surface resistance

|

IEC60093

|

Ω

|

>107

|

|||

*ITS: CSB company's internal test standards.

**Test temperatures are 23℃ unless otherwise stated.

PRODUCT TYPES

Sleeve Bearing

Flange Bearing

Thrust Washer

PRODUCT INFORMATION

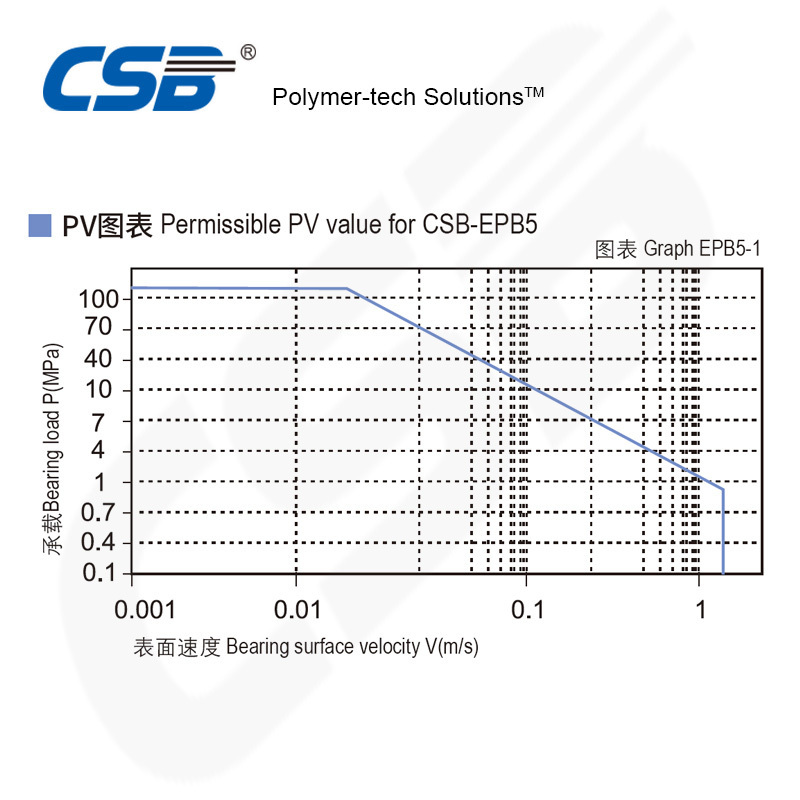

PV VALUE

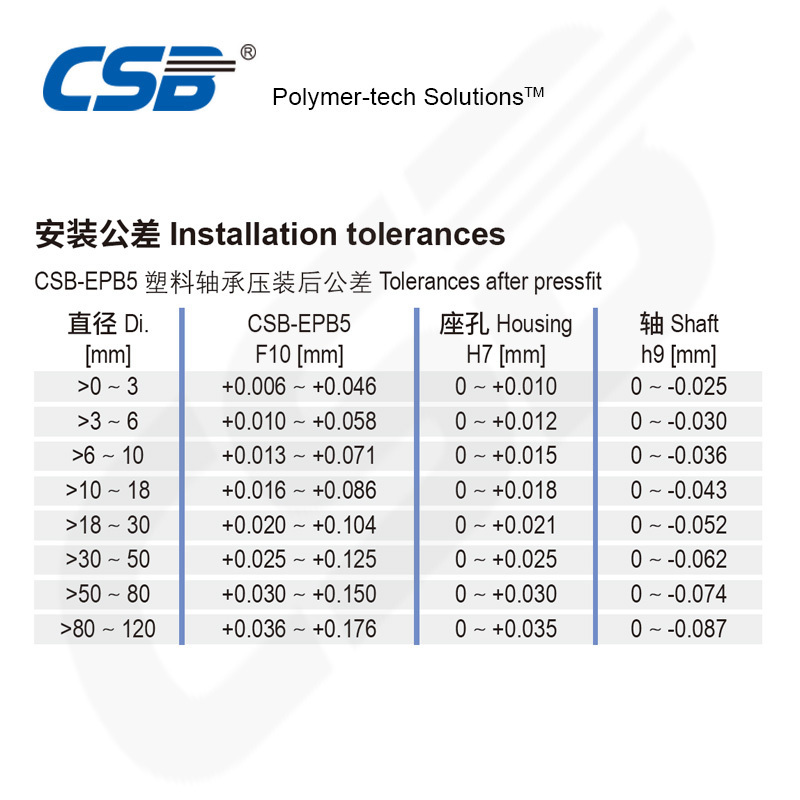

The max PV value of the CSB-EPB5F plastic bearings is 1.4N/mm2×m/s which determines the load capacity of bearing is inversely proportional to the speed. Please refer to the chart for more detailed information (Graph EPB5-1).

Load, speed and temperature

CSB-EPB5F allows the Max static load of 110Mpa, The max compressive deformation rate under the max load is listed in Graph EPB5-2, The actual load capacity of bearing is slightly less than 110Mpa, The bearing load is variable against the speed and temperature, Fast speed (Vmax: 1.5m/s) results into higher temperature (Tmax: 250℃) which decreases the load capacity of the bearing. Please refer to the Graph EPB5-3 for such variation.

CSB-EPB5F allows the Max static load of 110Mpa, The max compressive deformation rate under the max load is listed in Graph EPB5-2, The actual load capacity of bearing is slightly less than 110Mpa, The bearing load is variable against the speed and temperature, Fast speed (Vmax: 1.5m/s) results into higher temperature (Tmax: 250℃) which decreases the load capacity of the bearing. Please refer to the Graph EPB5-3 for such variation.

Friction factor, wear and shaft material

Friction factor

CSB-EPB5F Bearing Friction factor is increased along with the increasing of the operation speed under certain loading (See Graph EPB5-4). The friction factor of CSB-EP5 is decreased along with the loading increasing not over 20Mpa (see Graph EPB5-5). The friction factor will not change much along with the speed when the loading is over 20Mpa. The Graph EPB5-6 shows that the bearing could achieve its best performance when the counter shaft surface roughness is around Ra0.6 to Ra0.8.

Friction factor

CSB-EPB5F Bearing Friction factor is increased along with the increasing of the operation speed under certain loading (See Graph EPB5-4). The friction factor of CSB-EP5 is decreased along with the loading increasing not over 20Mpa (see Graph EPB5-5). The friction factor will not change much along with the speed when the loading is over 20Mpa. The Graph EPB5-6 shows that the bearing could achieve its best performance when the counter shaft surface roughness is around Ra0.6 to Ra0.8.

|

CSB-EPB

|

Dry

|

Grease

|

Oil

|

Water

|

|

Friction coef. μ

|

0.09~0.25

|

0.09

|

0.04

|

0.04

|

▉

Wearing and shaft material

Graph EPB5-7 and Graph EPB5-8 show the test results of the material CSB-EPB5F running against different shaft materials. It is suitable for stainless steel and hot rolled carbon steel shaft when the loading is less than 2Mpa and it will be more suitable for heat treated steel and carbon steel shaft when the loading is over 2Mpa. Graph EPB5-7 shows CSB-EPB5F is good for rotation operation. Specially, from the Graph EPB5-9, it is read that CSB-EPB5F is with better performance under high temperature around 150℃ comparing with under the ambient temperature of 23℃.

Graph EPB5-7 and Graph EPB5-8 show the test results of the material CSB-EPB5F running against different shaft materials. It is suitable for stainless steel and hot rolled carbon steel shaft when the loading is less than 2Mpa and it will be more suitable for heat treated steel and carbon steel shaft when the loading is over 2Mpa. Graph EPB5-7 shows CSB-EPB5F is good for rotation operation. Specially, from the Graph EPB5-9, it is read that CSB-EPB5F is with better performance under high temperature around 150℃ comparing with under the ambient temperature of 23℃.

Chemical resistance

Chemical Resistance of CSB-EPB5F is very good. It can work well in the heavy acid of 65%.

Chemical Resistance of CSB-EPB5F is very good. It can work well in the heavy acid of 65%.

Water absorption

The moisture absorption of CSB-EPB5F plastic plain bearings is 0.1% in standard atmosphere. The max. water absorption is 0.5% in water . These values are very low, CSB-EPB5 plastic palin bearings is very well suited for used in wet applications. .

The moisture absorption of CSB-EPB5F plastic plain bearings is 0.1% in standard atmosphere. The max. water absorption is 0.5% in water . These values are very low, CSB-EPB5 plastic palin bearings is very well suited for used in wet applications. .

UV resistance

CSB-EPB5F can maintain its performance to be stable even exposed in the UV ray for long period.

CSB-EPB5F can maintain its performance to be stable even exposed in the UV ray for long period.

STANDARD PRODUCTS

Hot Searches