- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

20000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Proman

-

Year:

-

2023

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1.5*0.65*2.0M

-

Hollow part volume:

-

5-20 Liter

-

Clamping Force (kN):

-

330

-

Power (kW):

-

40

-

Weight (KG):

-

380 KG

-

Function:

-

PET Bottle Blow Molding Machine

-

Key words:

-

PET plastic bottle blowing

-

Suitable bottle:

-

PET Bottle size 5-20 Liter

-

Material of main parts:

-

SUS304/316

-

Productivity:

-

60-180 PCS/H

-

Cavity:

-

1 Cavity

-

Power:

-

380V or Customer Made

-

Control system:

-

PLC with Touch Screen

-

Electrics:

-

Siemens,Mitsubishi,etc

-

Market:

-

Global Bottle Blow Molding Machine

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

270 mm

-

Max.Bottle Height(mm):

-

500 mm

-

Bottle Volume(ml):

-

20000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Proman

-

Year:

-

2023

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1.5*0.65*2.0M

-

Hollow part volume:

-

5-20 Liter

-

Clamping Force (kN):

-

330

-

Power (kW):

-

40

-

Weight (KG):

-

380 KG

-

Function:

-

PET Bottle Blow Molding Machine

-

Key words:

-

PET plastic bottle blowing

-

Suitable bottle:

-

PET Bottle size 5-20 Liter

-

Material of main parts:

-

SUS304/316

-

Productivity:

-

60-180 PCS/H

-

Cavity:

-

1 Cavity

-

Power:

-

380V or Customer Made

-

Control system:

-

PLC with Touch Screen

-

Electrics:

-

Siemens,Mitsubishi,etc

-

Market:

-

Global Bottle Blow Molding Machine

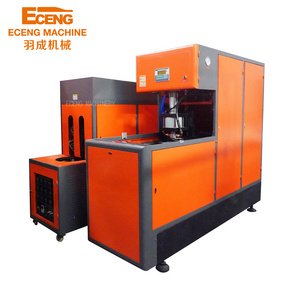

20 Litre Plastic Water Drum Making Machine / 5 Gallon PET Water Bottle Blower

Semi-automatic bottle blowing machine adopts direct pressure, icrocomputer control, two step blowing bottle.

The main blow tube blank PET mineral water bottles, beverage bottles, edible oil bottles, pharmaceutical plastic bottles, pesticide bottles, cosmetic bottles, etc..

It has various cavities and the maximum capacity of the products is 20L.

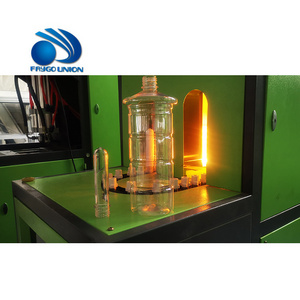

The gas path is designed to separate the gas and blowing, adopting low pressure(0.4-0.8Mpa) mould clamping, mould locking, sealing, stretching and high pressure(3-3.5Mpa) blowing form, and the gas-liquid locking structure, to not only ensure the clamping and locking action smoothly, also ensure the safety of mould and blowing quality, as a result can save the bottle perform material.

20 liter PET bottle blowing machine

20 liter PET bottle blowing machine

Advantages of Our Bottle Blow Molding Machine

1. Produce bottle from 5L to 20L(1-2 cavity)

2. Output capacity up to 180 for 20L using one-cavity blow mold

3. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms

8. Operated only by one person without special training

9. Simple installation & startup adjustment

10. Waste rate of finished bottle is less than 0.2%

| Model | Item | Unit | PM-12 | PM-8Y | PM-1500 | PM-1-20 |

| Theoretical output | Pcs/H | 500 | 900 | 1800 | 90 | |

| Product | Volume | L | 5.0 | 2.0 | 2.0 | 20 |

| MAX.Height | mm | 360 | 360 | 360 | 550 | |

| MAX.Diameter | mm | 120 | 105 | 105 | 300 | |

| Mould | Number of cavities | / | 1 | 2 | 4 | 1 |

| Mould piate dimension(L*H) | mm | 490*470 | 490*405 | 490*405 | 620*620 | |

| Mould thinkness | mm | 250 | 220 | 220 | 380 | |

| Mould opening stroke | mm | 220 | 180 | 180 | 380 | |

| Electrical | Power | / | 220_380V/50_60HZ | |||

| Total power | KW | 11 | 11 | 21 | 36 | |

| Heating power | KW | 10 | 10 | 20 | 37 | |

| Machine | Main body dimension (L*W*H) | M | 1.5*0.65*2.0 | 1.5*0.65*2.0 | 1.5*0.65*2.0 | 2.1*0.75*1.6 |

| Main body weight | KG | 600 | 550 | 550 | 900 | |

| Pre-heater(L*W*H) | M | 1.5*0.65*1.5 | 1.4*0.65*1.5 | 1.8*0.65*1.5 | 2.7*0.7*1.6 | |

| Pre-heater weight | KG | 300 | 300 | 350 | 400 | |

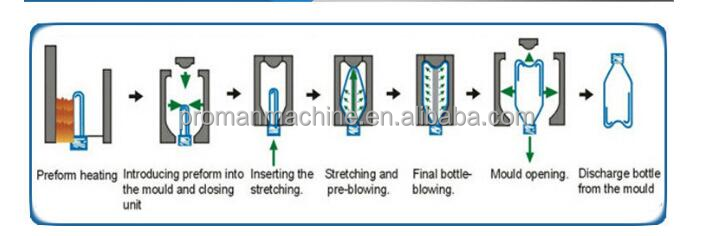

PET preform→Autoloader→reheater →molding→ bottles

Customized service

We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3.We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6.24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7.12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9.Good after-sale service offered, please get back to us if you got any questions.

Quality Control

We have separate quality control department, which make sure the raw materials are qualified,also ensure the machine running smoothly.

If you want to know more information about the product,Send inquiry to us, we will solve any of your problems and send you running video for reference.