- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

20000 KG

-

After-sales Service Provided:

-

Video technical support

-

Width:

-

2000-5000

-

Appicable fiber:

-

carbon fiber, glass fiber

-

Capacity:

-

200-400KG/H

-

Possible products:

-

glassfiber felt

-

Thickness:

-

1-2cm

Quick Details

-

Voltage:

-

380-600v

-

Place of Origin:

-

China

-

Power:

-

10000 W

-

Weight:

-

20000 KG

-

After-sales Service Provided:

-

Video technical support

-

Width:

-

2000-5000

-

Appicable fiber:

-

carbon fiber, glass fiber

-

Capacity:

-

200-400KG/H

-

Possible products:

-

glassfiber felt

-

Thickness:

-

1-2cm

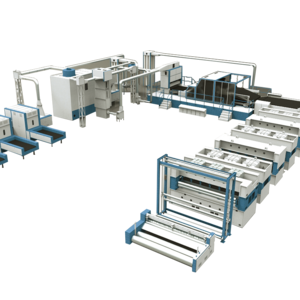

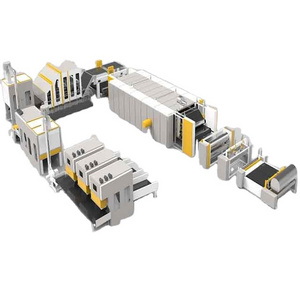

Glassfiber Felts Production Line.

The product range includes Single- and Double-Board Needle Looms, Tandem Needle Looms, Velour-, Structuring Needle loom and Patterning Needle Looms.

Possible NEEDLE PUNCH PRODUCTS:

· Wipes

· Geotextiles

· Roofing felts

· Automotive headliners

· Automotive velour

· Artificial leather/coating substrates

· Automotive substrates

· Carpets (structured & flat)

· Hometex

· Technical felts (filtration)

Fiber preparation.

Automatically feed fibers into the production line, with higher precision and less labors.

Different feeding solutions optional.

Carding machine

Carding fiber into fine fibers, and ready for next process. Different sizes designed for different capacity request.

Double cylinder for finer fiber carding effects.

Single cylinder carder for higher capacity.

Needle punching.

Needle punching to help fabric gains strength.

Different needle machine settings depend on fabric specifications.

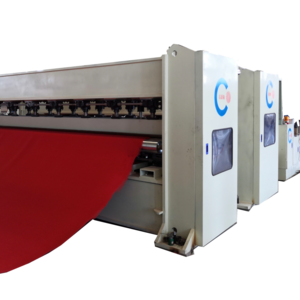

Calender machine

Calender machine to compress fabric into certain thickness, smooth fabric surface. Also help soft waddings into certain thickness, make wadding surface smooth and hard.

Bale openers

Pre-opener

Carding machine

Cross Lapper

Vertical Lapper

Air Laid Machine

Double Belt Oven

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Chemical Bond Oven

Winder&Cutter

Fiber Roll Packer