- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PB-800

-

Power:

-

25

-

Material:

-

wood&foam board

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

5000 kg

-

Name:

-

Fridge Crusher Machine

-

Raw material:

-

Scrap household appliance

-

Key Words:

-

refrigerator disposal and recycling equipment

-

Application:

-

Abandoned metal

-

Machine Type:

-

Recyling machine

-

Function:

-

Broken refrigerator

-

Usage:

-

Abandon metal tear

-

Keyword:

-

waste fridge recycling machine

-

Advantage:

-

high efficiency

Quick Details

-

Production Capacity:

-

600KG/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Paibo

-

Model Number:

-

PB-800

-

Power:

-

25

-

Material:

-

wood&foam board

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

5000 kg

-

Name:

-

Fridge Crusher Machine

-

Raw material:

-

Scrap household appliance

-

Key Words:

-

refrigerator disposal and recycling equipment

-

Application:

-

Abandoned metal

-

Machine Type:

-

Recyling machine

-

Function:

-

Broken refrigerator

-

Usage:

-

Abandon metal tear

-

Keyword:

-

waste fridge recycling machine

-

Advantage:

-

high efficiency

PB Fridge Crusher Machine Disposal And Recycling Of Refrigerator Equipment

This product is a customized product, and the display price is for reference only

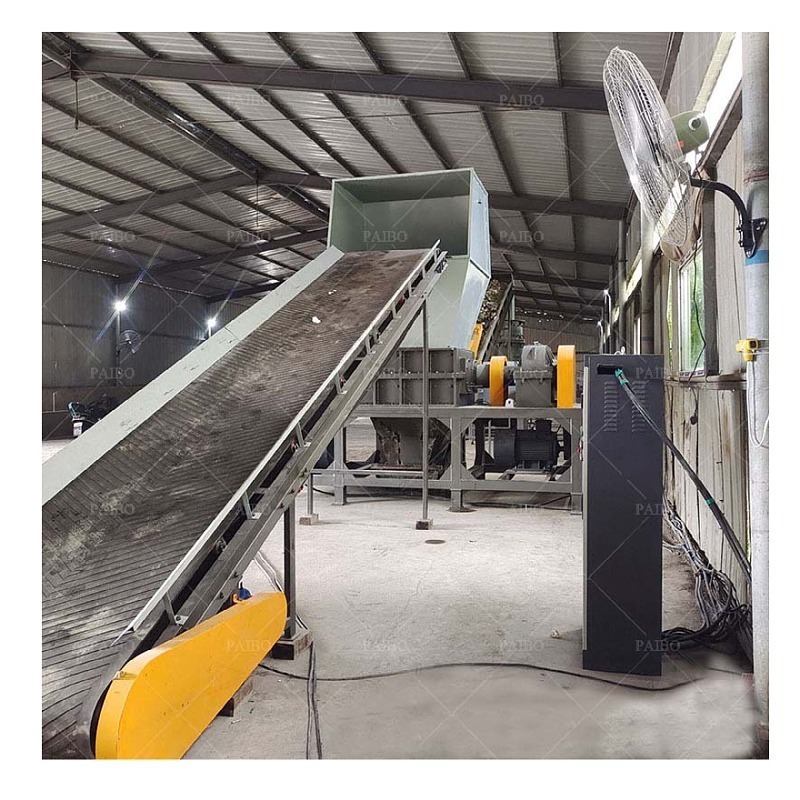

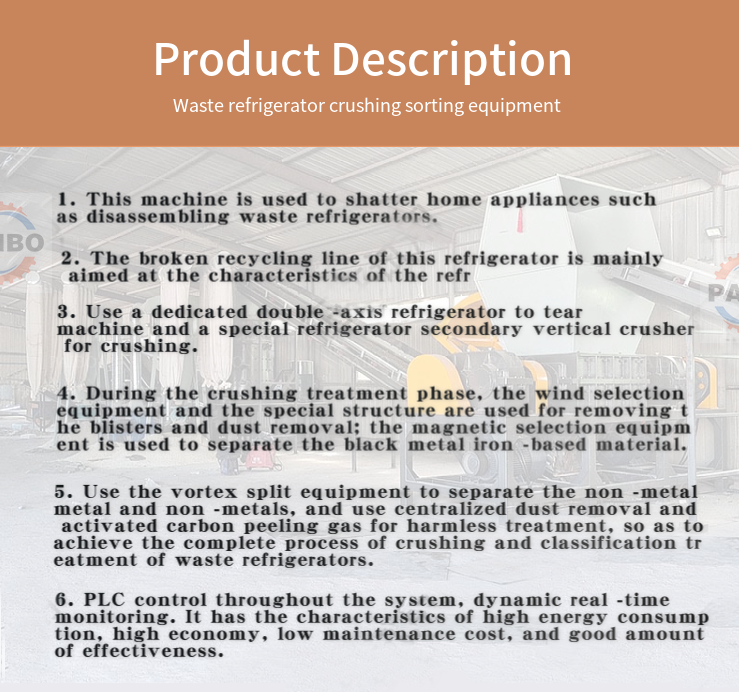

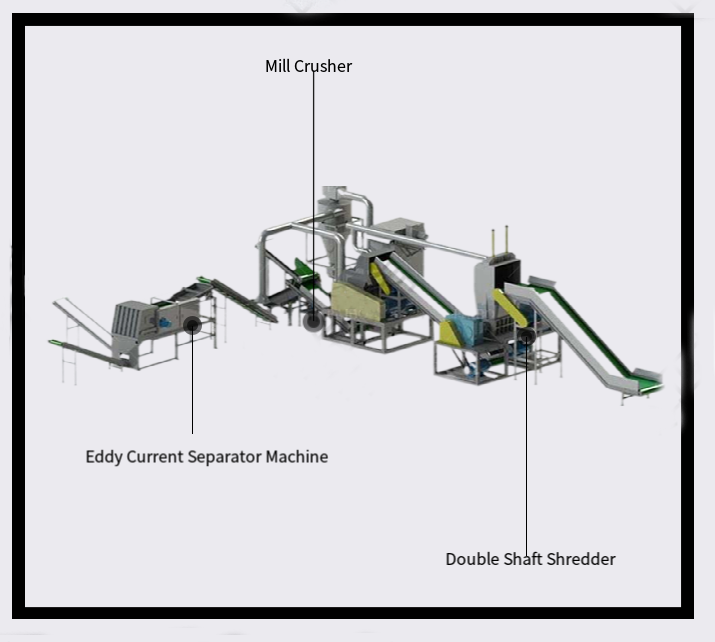

The refrigerator crusher first uses a doubleaxis fragmentation machine. It can be rough and crushed to various types of refrigerators and freezers. The size of the refrigerator tear machine is customized according to the customer's requirements for yield. There are 800 types, 1200, 1200, etc.

1. Its tools must have long life. Our refrigerator tear machine knife blade uses a high -intensity alloy tool, which has the advantages of high strength, good toughness, strong durability, abrasion resistance, and impact resistance.

2. Standardized structure characteristics. The structure of the tearr of each model is standardized. For example, the number of roller teeth of the twoaxis spacing and one machine should be standardized according to productivity.

3. Doubleroller tear machines are equipped with intimate and intelligent removal device, which can automatically remove the adhesive material on the crusher wall.

4. Double roller tear machines are different from other crusher. It has a large crushing ratio, and there is not much requirements for the water scores of crushing materials, and it will not be blocked. It will not be blocked. Advantage.

5. High efficiency and ensure the actual output of customers.

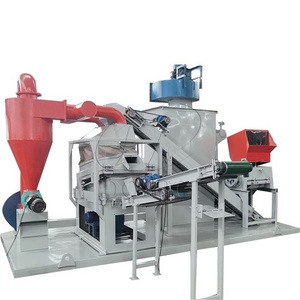

The scaling refrigerator is a modular design. After manual dismantling, the harmful gas is collected and collected, and the compressor is demolished. The disassembly refrigerator is sorted out by the crusher and the magnetic selection machine, and the purity can reach more than 98%. The rest of the materials are selected by the vortex amplifier to select non -ferrous metals and plastic. Copper metals are separated from copper and aluminum through airflow sorting machines, and the separation rate can reach more than 95%. Plastic can be divided into different materials through electrostatic sorting machines. The entire production line has foam plastic collection and dust collection system. By the purity of more than 97%.