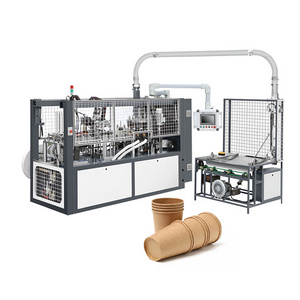

It makes paper cups after running a whole procedure of automatic pre-printed cup-fan-paper feeding, cup-side-body welding(heater or ultrasonic), silicone-oil lubricating(for topcurling,Dimethyl silicone oil 201,Food Grade), roll bottom auto feeding and

bottom-disk punching, bottom pre-heating and pre-folding, main heating, bottom knurling, top curling, cup discharging, collection.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

GaWang Machine

-

Voltage:

-

220V±10%

-

Dimension(L*W*H):

-

2.6x0.95x1.4 m

-

Weight:

-

1500 kg, About 1500 Kg

-

Cutting Speed:

-

20-150m/min

-

Max. Unwinding Dia.:

-

500mm

-

Max. Web Width:

-

320 mm

-

Max. Mould Cutting Width:

-

300 mm

-

Max. Mould Cutting Length:

-

300 mm

-

Orientation Accuracy:

-

±0.15 mm

-

Total Power:

-

3 Kw

-

Power Voltage:

-

220V±10%

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

300 times/min

-

Max. workable width:

-

350mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

GaWang Machine

-

Voltage:

-

220V±10%

-

Dimension(L*W*H):

-

2.6x0.95x1.4 m

-

Weight:

-

1500 kg, About 1500 Kg

-

Cutting Speed:

-

20-150m/min

-

Max. Unwinding Dia.:

-

500mm

-

Max. Web Width:

-

320 mm

-

Max. Mould Cutting Width:

-

300 mm

-

Max. Mould Cutting Length:

-

300 mm

-

Orientation Accuracy:

-

±0.15 mm

-

Total Power:

-

3 Kw

-

Power Voltage:

-

220V±10%

Products Description

Description

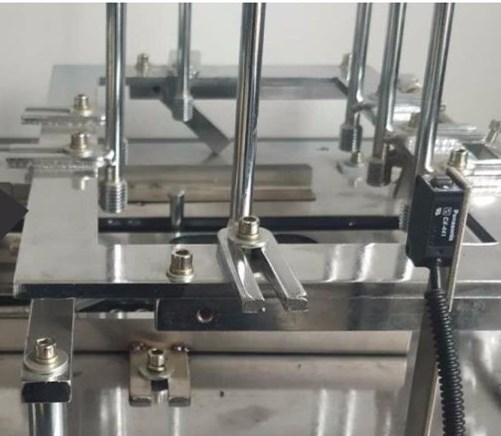

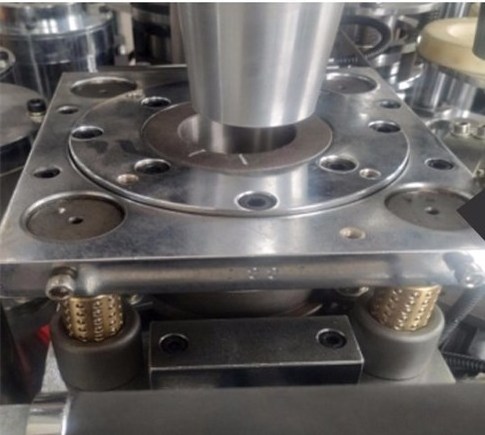

Overall frame structure

The overall design is a box structure with welded ribs on the sides. The spray lubrication system is used to reduce wear and dissipate heat effectively, so that the machine has a longer life and more stable operation.

Machine Highlights

1. Different from ordinary paper cup machine, this model adopts full-body square steel structure, which is not more compact and stable under the condition of high-speed operation.

2.The main motor uses a gear reducer motor, using imported bearings NSK.

3.The use of fully automatic closed lubrication system, without the need for manual oil lubrication, can ensure that the machine runs for a long time without interruption at high speed.

4. Parts and components are produced in a standardized manner with strong versatility and good interdependence performance, which is convenient for equipment maintenance.

Mechanical quality assurance

2.The main motor uses a gear reducer motor, using imported bearings NSK.

3.The use of fully automatic closed lubrication system, without the need for manual oil lubrication, can ensure that the machine runs for a long time without interruption at high speed.

4. Parts and components are produced in a standardized manner with strong versatility and good interdependence performance, which is convenient for equipment maintenance.

Mechanical quality assurance

1. All moving parts on the table are easily accessible, which is convenient for daily cleaning and

maintenance.

2. All the moving parts under the countertop are shower-type lubricated and replaced with the specified lubricating oil every 4 to 6 months.

maintenance.

2. All the moving parts under the countertop are shower-type lubricated and replaced with the specified lubricating oil every 4 to 6 months.

|

Specification of paper cup

|

3~16oz

|

|

Output

|

65-85pcs/min

|

|

Main motor power

|

2.2kw

|

|

Heating power

|

8kw

|

|

Installed power

|

15kw

|

|

Air Pressure Request

|

0.4m3/min, 0.5Mpa

|

|

Applicable raw paper

|

190~350g/m2(single/double-sided PE coated paper)

|

|

Machine weight:

|

3100kg

|

After-sales Service

More Products

Certifications

Hot Searches