- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*900mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

ACUT LASER

-

Weight (KG):

-

960 KG

-

Laser power:

-

1000-20000W

-

Keyword:

-

fiber laser

-

Laser source:

-

RAYCUS

-

Working area:

-

1300*900mm

-

Name:

-

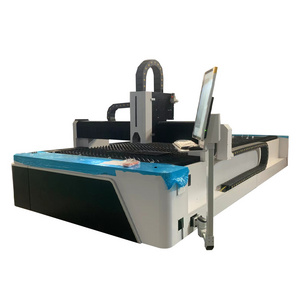

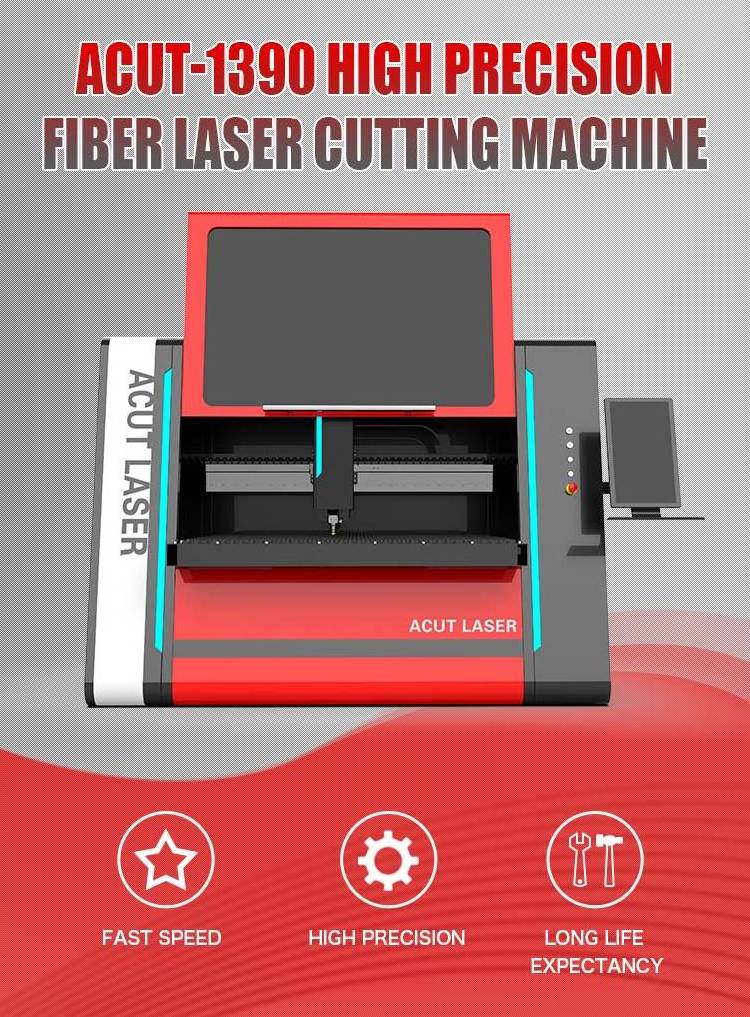

Fiber Laser Cutting Machine Metal

-

Model:

-

ACUT-1390S

-

Power supply:

-

380V/50/60HZ

-

Driving system:

-

Servo motor

-

After-sales Service Provided:

-

Online support

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

35m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*900mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

ACUT LASER

-

Weight (KG):

-

960 KG

-

Laser power:

-

1000-20000W

-

Keyword:

-

fiber laser

-

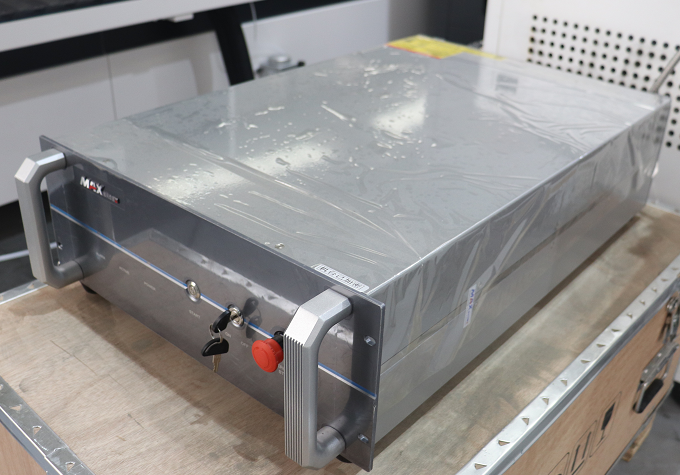

Laser source:

-

RAYCUS

-

Working area:

-

1300*900mm

-

Name:

-

Fiber Laser Cutting Machine Metal

-

Model:

-

ACUT-1390S

-

Power supply:

-

380V/50/60HZ

-

Driving system:

-

Servo motor

-

After-sales Service Provided:

-

Online support

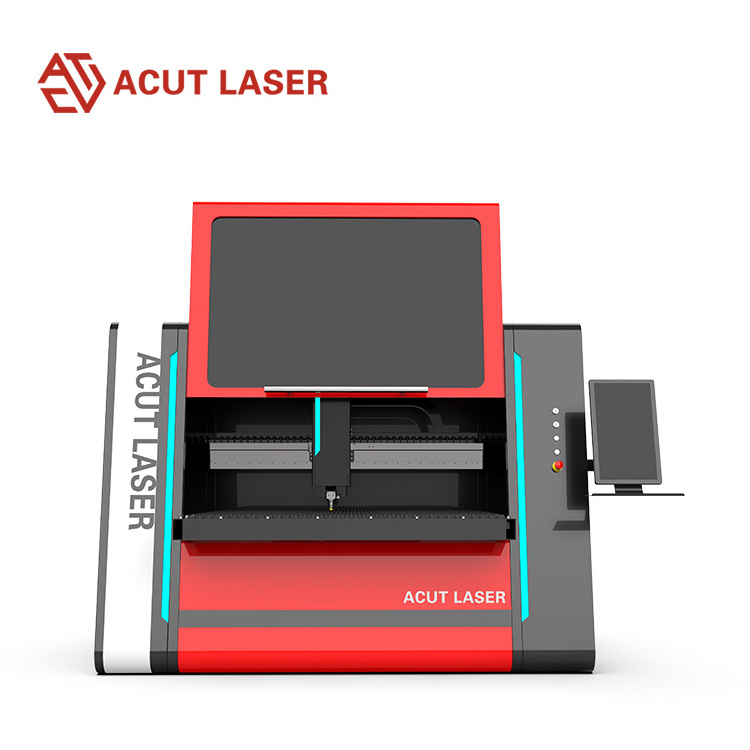

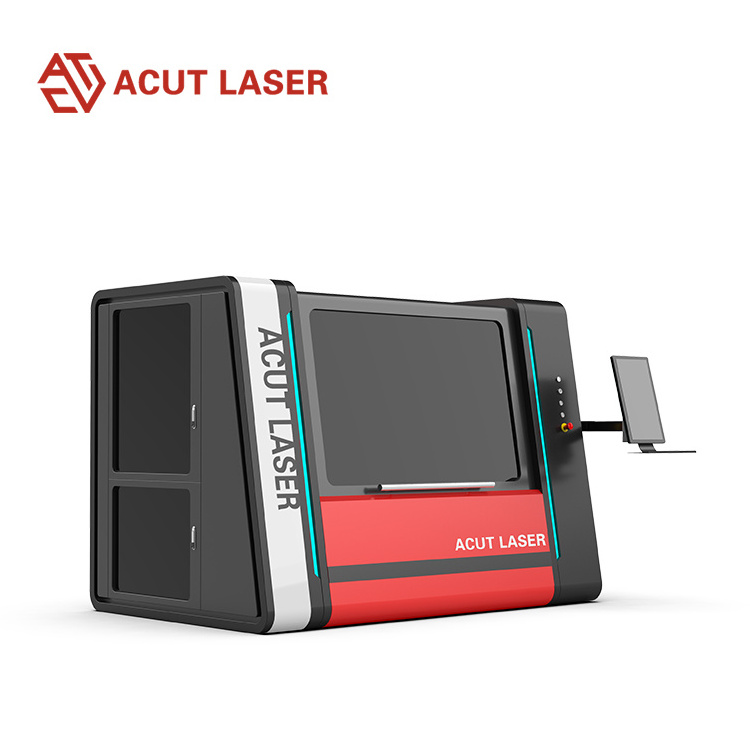

Machine Description & Specifications

|

Description and Specifications

|

|

|

|

Model NO.

|

ACUT-1390S Metal Sheet Fiber laser cutting machine

|

|

|

work Area

|

1300x900mm

|

|

|

laser head

|

Cypcut

|

|

|

Laser source

|

1000w (1500w 2000w 3000w Optional)

|

|

|

Cutting thickness

|

0.2-10mm(depend on material)

|

|

|

Max cutting speed

|

40m/min

|

|

|

Control system

|

Cypcut

|

|

|

Positioning accuracy

|

0.03mm/min

|

|

|

Transmission

|

Taiwan TBI ball screw

|

|

|

XY motor and driver

|

Japanese FUJI Servo Motor

|

|

|

Material

|

Stainless steel/Carbon steel/Aluminum/Brass Etc.

|

|

|

Color

|

Optional

|

|

|

Supported Format

|

PLT, DST, DXF, BMP, AI, Support AutoCAD, CorelDraw Output Directly

|

|

|

Daily working hours

|

24 hours without intermission

|

|

|

Warranty time

|

Three years (all accessories)

|

|

|

Package

|

wooden box

|

|

|

Chinese and English fonts

|

YES

|

|

|

CAD

|

CAD graphics in various formats can be invoked

|

|

|

help function

|

INCLUDE

|

|

(1) High photo-voltaic conversion rate (above 30%), which helps to save electricity and costs greatly to guarantee the highest production efficiency.

(2) When processing, the laser only consumes electricity and doesn’t need extra gas, bringing the minimum operation and maintenance costs.

(3) Adopting semiconductor modular and redundancy design, without any optical glass in resonant cavity and without start time, so it is in high stability and doesn’t need adjusting and maintaining, which saves the costs and time. In this point, the traditional laser is not comparable.

(4) The output wavelength of fiber laser is 1.06μm, which is a tenth of CO2 wavelength. The output beam is in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great power to cut and weld to make the lowest processing costs.

(5) The laser is transmitted by fiber and there is no complicated reflector or other light guiding system. The optical system is very simple and stable and doesn’t need maintaining.

(6) The laser is output by fiber, which makes the mechanical system design easier and it’s very likely to be connected with robot or multidimensional work platform.

(7) With an optical shutter and by light splitting through fiber cables, the laser source can be used by several machines at the same time.

(8) The fiber laser is small and light and it’s easy to be moved.

(2) When processing, the laser only consumes electricity and doesn’t need extra gas, bringing the minimum operation and maintenance costs.

(3) Adopting semiconductor modular and redundancy design, without any optical glass in resonant cavity and without start time, so it is in high stability and doesn’t need adjusting and maintaining, which saves the costs and time. In this point, the traditional laser is not comparable.

(4) The output wavelength of fiber laser is 1.06μm, which is a tenth of CO2 wavelength. The output beam is in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great power to cut and weld to make the lowest processing costs.

(5) The laser is transmitted by fiber and there is no complicated reflector or other light guiding system. The optical system is very simple and stable and doesn’t need maintaining.

(6) The laser is output by fiber, which makes the mechanical system design easier and it’s very likely to be connected with robot or multidimensional work platform.

(7) With an optical shutter and by light splitting through fiber cables, the laser source can be used by several machines at the same time.

(8) The fiber laser is small and light and it’s easy to be moved.

Sample:

Recommend Products

Our Service

Hot Searches