- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2300*2000*1500 mm

-

Year:

-

2022

-

Power (kW):

-

11 kW

-

Weight (KG):

-

1200 KG

-

Applicable Industries:

-

Tire Recycling

-

Certification:

-

CE ISO

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2300*2000*1500 mm

-

Year:

-

2022

-

Power (kW):

-

11 kW

-

Weight (KG):

-

1200 KG

-

Applicable Industries:

-

Tire Recycling

-

Certification:

-

CE ISO

-

Marketing Type:

-

Ordinary Product

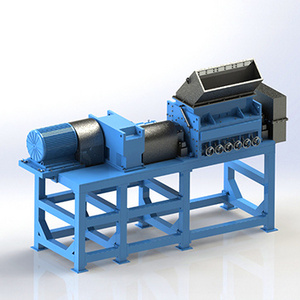

AYuxi Tire Wire Removing Machine of Tire Steel Machinery Recycling

Application of Tire Wire Removing Machine

This tire wire removing machine is suitable for use in the waste tire recycling industry. It can pull out the large strands of steel wire on both sides of the tire, thus separating the main steel wire from the tire. It is an important step in the recycling of used tires.

Working Principle Of Tire Wire Drawing Machine

The tire steel removing machine uses the hydraulic principle, the motor drives the oil pump to operate, the oil pump drives the main drawing cylinder and the safety cylinder. The main cylinder of the drawing process has a large tonnage, which can easily pull out the tire wire, and the auxiliary safety cylinder ensures the safety during the drawing process. To avoid the situation of broken or rebounding and hurting people.

Instructions for Tire Machinery Recycling

1. When using the machine, please add hydraulic oil first. Two-thirds of the hydraulic oil is added to the fuel tank.

2. When using this machine to pull the inner ring of the tire, remember to force the drawing. When the upper part of the tire is seriously concave during the drawing process, the cylinder should be moved back. When the tire returns to normal, the drawing is performed.

Parameter of Yuxi Tyre Stripping Machine

| Model: YX-DH1200 |

| Capacity: 80~120 pcs |

| Tire size request: ≤Φ1200 |

| Power: 15KW |

| Pull Power: 15T+15T |

| Weight: 6.5 |

| Size:2300*2000*1500mm |

Work Flow of Semi Automatic Tire Recycling Machine

1. Cutting machine: remove the tire ring

2. Slitting machine: cut the tire into strip rubber

3. Dicer: Cut the strip rubber into pieces (about 5*5cm)

4. Double roll rubber powder machine: crush the rubber block into rubber powder or rubber particles (5-40mesh)

5. Vibrating screen: Sorting rubber particles of different sizes, the particles with too large size are sent back to the rubber powder machine for secondary crushing.

6. Magnetic separator: separating steel wire from rubber wire mixture

7. Sub-vibrating screen: sorting rubber particles of different sizes, and the oversized particles are sent back to the rubber powder machine for secondary crushing.

8. Magnetic separator: remove the small wire that may remain

9. Fiber separator: remove foreign matter and fiber

Our factory is located in Zhengzhou, China. After years of development, we have two factories and independent design and development team. Welcome to our factory to visit the test machine.