- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

0.37

-

Range of Spindle Speed(r.p.m):

-

60 - 580 r.p.m

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Tencan

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

710*400*240MM

-

Weight (KG):

-

35 KG

-

Product name:

-

lab roller ball mill

-

Speed control mode:

-

Frequency control

-

Roller speed:

-

60-580rpm

-

Mill mode:

-

dry mill/wet mill

-

Working mode:

-

1 jar work one time

-

Power:

-

0.37KW

-

Weight:

-

35KG

-

Mill jar material:

-

stainless steel,nylon,ceramics,PTFE,PU,etc.

-

Matched mill media:

-

Alumina balls,zirconia balls,agate balls,stainless steel balls,etc.

Quick Details

-

Output (kg/h):

-

0.1 - 1.75 kg/h

-

Feeding Size (mm):

-

1 - 5 mm

-

Output Size (mesh):

-

200 - 500 mesh

-

Power (kW):

-

0.37

-

Range of Spindle Speed(r.p.m):

-

60 - 580 r.p.m

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Tencan

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

710*400*240MM

-

Weight (KG):

-

35 KG

-

Product name:

-

lab roller ball mill

-

Speed control mode:

-

Frequency control

-

Roller speed:

-

60-580rpm

-

Mill mode:

-

dry mill/wet mill

-

Working mode:

-

1 jar work one time

-

Power:

-

0.37KW

-

Weight:

-

35KG

-

Mill jar material:

-

stainless steel,nylon,ceramics,PTFE,PU,etc.

-

Matched mill media:

-

Alumina balls,zirconia balls,agate balls,stainless steel balls,etc.

Recommend Products

Products Description

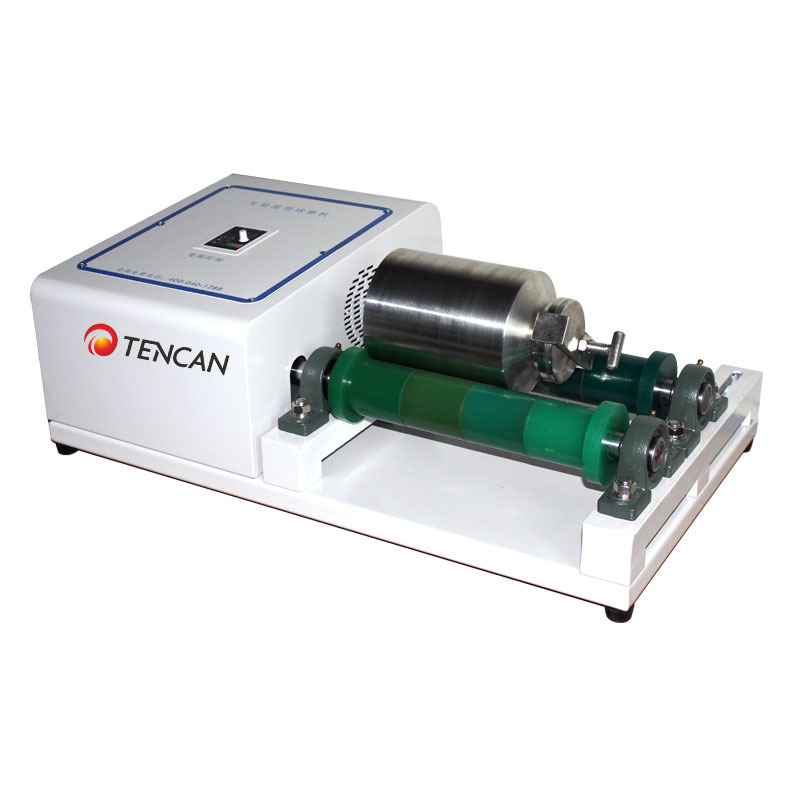

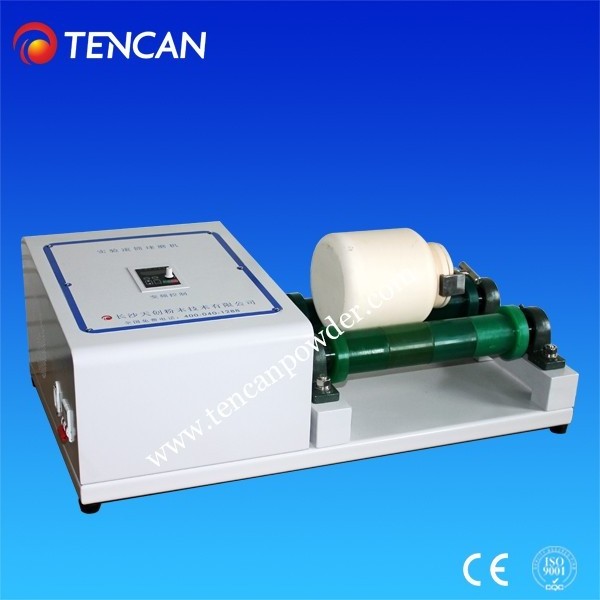

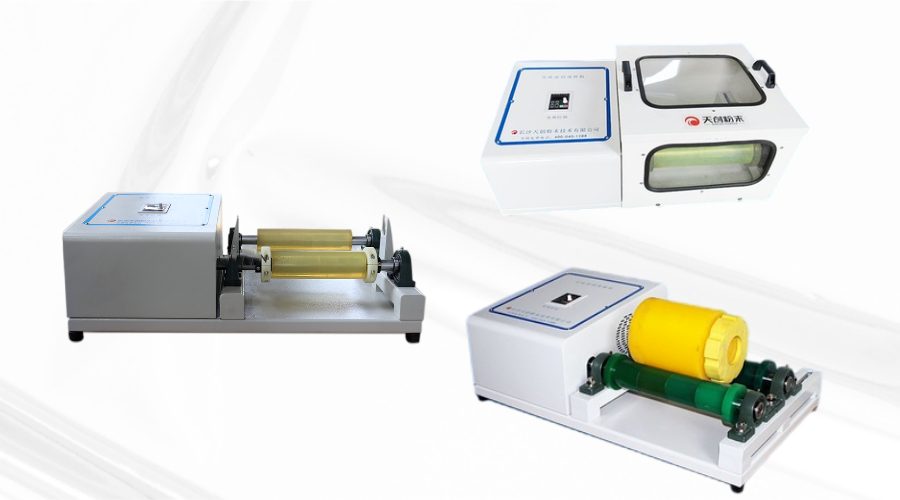

China Tencan Unmanned Lab Roller Ball Mill, Mini Roller Mill, Roller Mill Powder Making Machine

|

Category

|

Model

|

Power Supply

|

Rotate Speed

|

Max Load for Each Jar

|

Dimensions

/weight |

|

1 Working Position

|

QM-5

|

220V or 110V Single phase

0.37KW |

60-570rpm

|

35KGS

|

730*415*260mm

32KGS |

|

1 Working Position

|

QM-15

|

220V or 110V Single phase

0.75KW |

60-570rpm

|

80KGS

|

845*435*270mm

45KGS |

Lab roll ball mill

is a kind of equipment used for ultra-fine grinding and mixing for laboratory and small batch production. The machine is preferred equipment for scientific research, education, experiment and production due to its advantages such as elegant and fashion design, compact structure, easy operation, high efficiency, and uniform granularity. It is widely applied to industries of electronic material, magnetic material, ceramic glaze, metal powder, nonmetallic minerals, new materials, and etc.

Working Principle of Roll Ball Mill

When the roll ball mill works, the grinding media and the materials inside the tank are rotated to a certain height. Due to the gravity, they fall down from the tube wall. Materials are crushed by impact action of the grinding media, friction and shearing action of grinding media’s rolling and sliding.

Features of Roll Ball Mill

1. Compact structure, easy operation

2. High efficiency and uniform granularity

3. Milling pot in different size can be put on the driven rubber roller within a certain range by means of adjusting space between the rubber rollers.

4. It is convenient to change pots and suitable for both wet and dry grinding.

Available & Matched Accessories

Our factory provides all kinds of mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU

mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill

balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

Hot Searches