- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

33 kN

-

Theoretical Shot Volume(cm³):

-

192 cm³

-

Injection Rate (g/s):

-

102 g/s

-

Injection Weight (g):

-

175 g

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

21

-

Weight (KG):

-

2600 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

100 mm

-

Model Number:

-

KT120

-

Brand Name:

-

KETAI

-

Power (kW):

-

7.2 kW

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

370mm

-

Distance between Tie Bars(Height)(mm):

-

370mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

33 kN

-

Theoretical Shot Volume(cm³):

-

192 cm³

-

Injection Rate (g/s):

-

102 g/s

-

Injection Weight (g):

-

175 g

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

21

-

Weight (KG):

-

2600 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

100 mm

-

Model Number:

-

KT120

-

Brand Name:

-

KETAI

-

Power (kW):

-

7.2 kW

Products Description

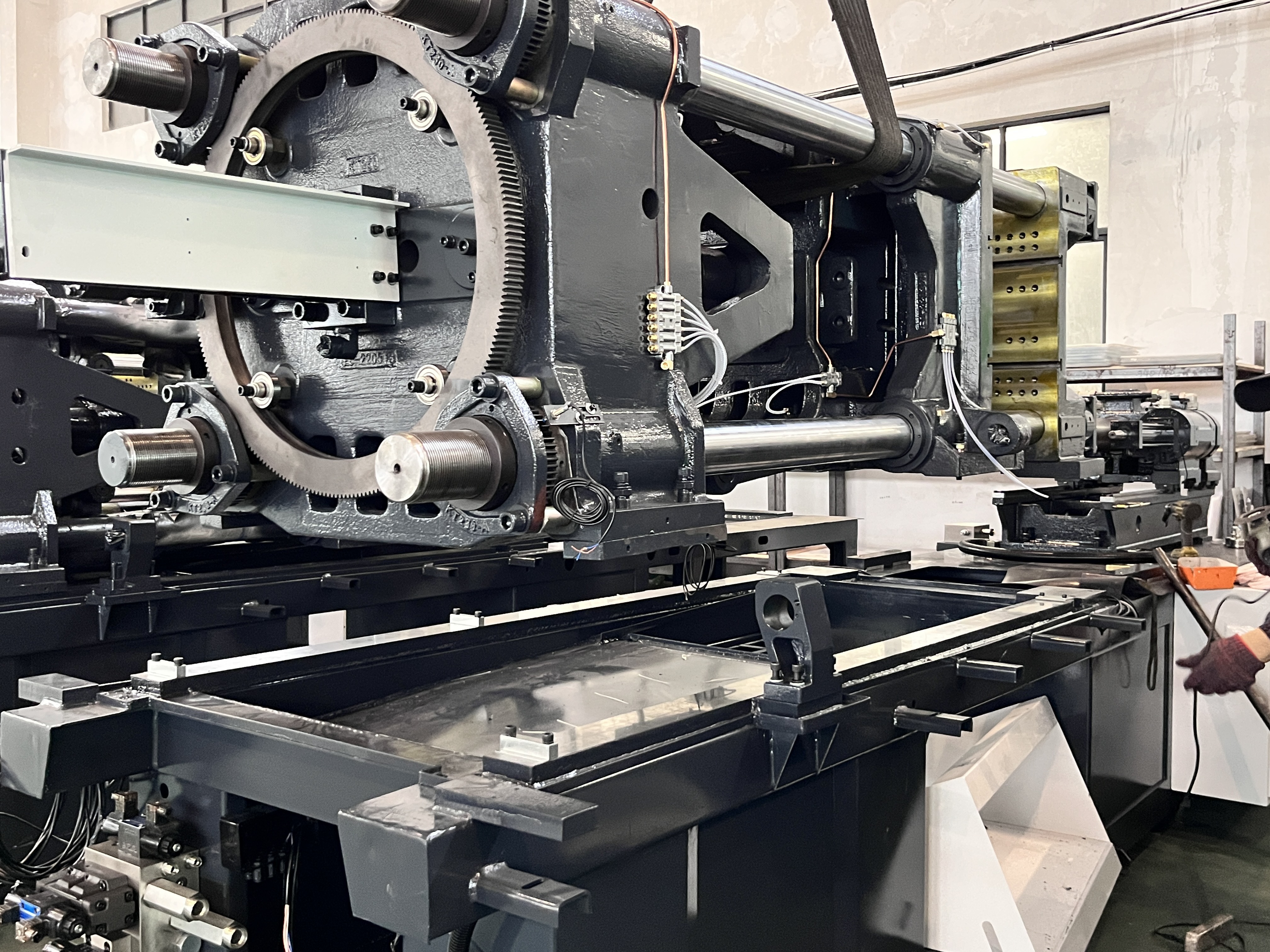

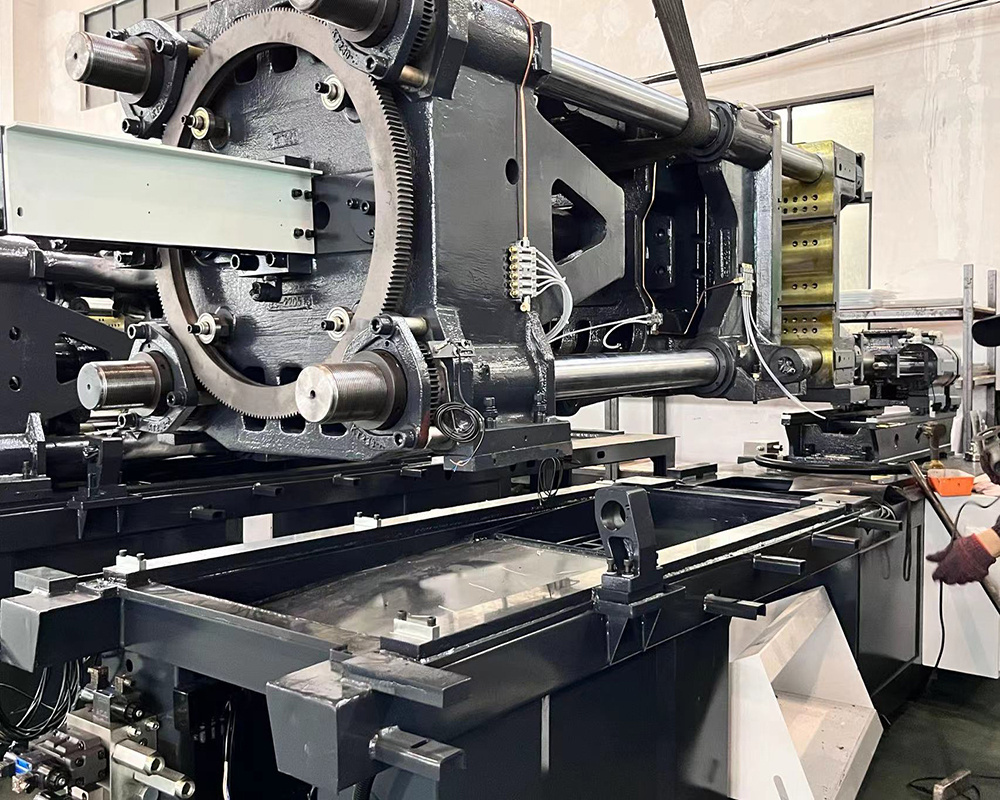

CLAMPING UNIT

High-rigidity clamping system maximizes product quality and stability Improves effective protection of molds, improves efficiency and saves costs for customers

The volume quantitative lubrication distribution system can ensure that each lubrication point is fully lubricated, and the oil distribution is even, the lubrication efficiency is high, and the life of the friction parts is greatly increased

The second plate foot has an adjustable slider structure, which is convenient for adjustment after wear and tear to prolong the service life of the machine.

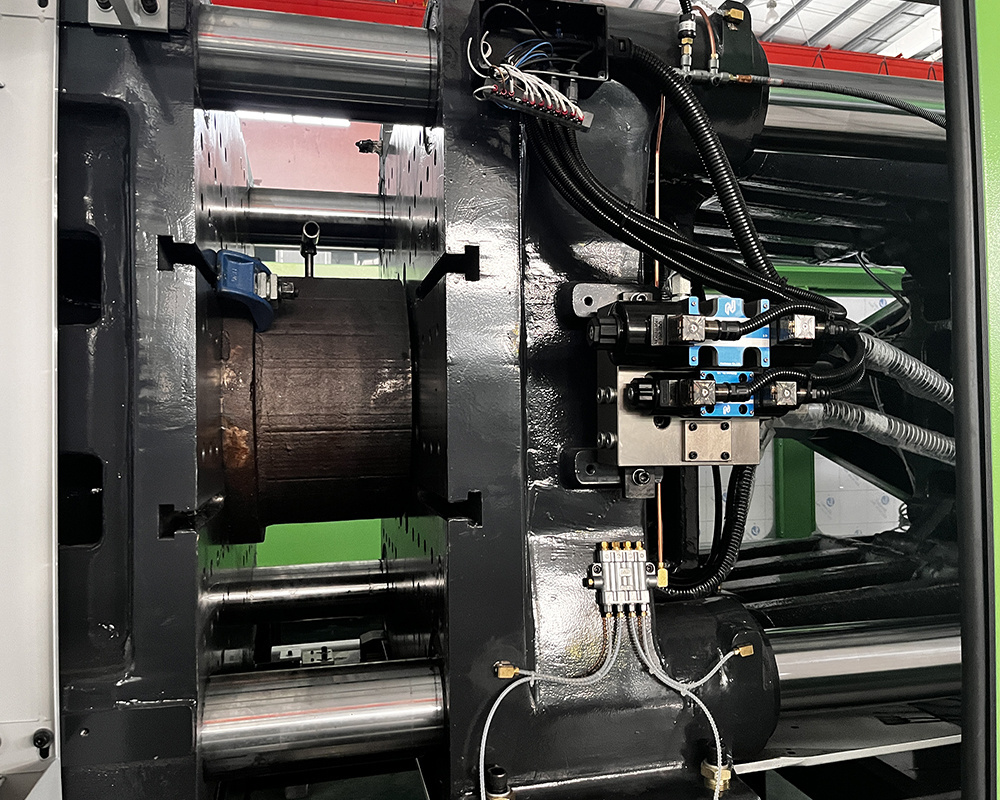

INJECTION UNIT

Using double linear guide rails, the friction force is small, making the movement faster, more precise and more stable

Double-bar injection mechanism, stable, accurate and fast injection, standard high-quality screw barrel, good plasticizing effect, durable.

Different kinds of product materials have corresponding models.

HYDRAULIC UNIT

Due to the high-response servo motor and internal gear pump power system, it only takes 0.05 seconds for the injection molding machine to reach the maximum output. Compared with the traditional hydraulic injection molding machine, the response speed is significantly faster, effectively shortening the cycle and improving the time.

ELECTRONIC UNIT

The main components of the special control system for imported injection molding machines adopt "TFT" true-color display system, a well-known domestic and foreign accessory, a full-digital CAN control system and high-quality electrical components to make the system operation accurate, stable and reliable

PRODUCT SPECIFICATIONS

|

SPECIFICATION

|

UNIT

|

KT120

|

|

|

|

|||

|

injection device

|

|

A

|

B

|

C

|

|

|||

|

screw diameter

|

mm

|

35

|

38

|

42

|

|

|||

|

screw length-diameter ratio

|

L/D

|

23

|

21

|

19

|

|

|||

|

theoretical injection presure

|

Mpa

|

219

|

186

|

158

|

|

|||

|

theoretical injection volume

|

cm

3

|

163

|

192

|

235

|

|

|||

|

injection weight

|

g

|

148

|

175

|

213

|

|

|||

|

injection rate

|

g/s

|

87

|

102

|

125

|

|

|||

|

Screw Max Speed

|

rpm

|

213

|

|

|

|

|||

|

Clamping Unit

|

|

|

|

|

|

|||

|

clamping force

|

kn

|

1200

|

|

|

|

|||

|

molding stroke

|

mm

|

345

|

|

|

|

|||

|

space between tie-bars

|

mm

|

370*370

|

|

|

|

|||

|

max mold thickness

|

mm

|

380

|

|

|

|

|||

|

min mold thickness

|

mm

|

150

|

|

|

|

|||

|

ejection force

|

kn

|

33

|

|

|

|

|||

|

ejection stroke

|

mm

|

100

|

|

|

|

|||

|

number of rods

|

piece

|

5

|

|

|

|

|||

|

other

|

|

|

|

|

|

|||

|

system pressure

|

mpa

|

16

|

|

|

|

|||

|

motor power

|

kw

|

15.5

|

|

|

|

|||

|

electric heating power

|

kw

|

7.2

|

|

|

|

|||

|

dimenions

|

m

|

3.88*1.17*1.75

|

|

|

|

|||

|

oil tank capacity

|

L

|

200

|

|

|

|

|||

|

machine weight

|

T

|

2.6

|

|

|

|

|||

Hot Searches