- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Handwheel

-

Product:

-

Valve Handwheel

-

Process:

-

Shell Mould Casting

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

10

-

Marketing Type:

-

Custom

-

Core Components:

-

Handwheel

-

Product:

-

Valve Handwheel

-

Process:

-

Shell Mould Casting

OEM Shell Moulding Casting Parts Cast Iron Valve Handwheel

Products Description

|

Name

|

OEM Valve Accessory- Handwheel

|

|

OEM

|

Acceptable

|

|

Materials

|

Cast iron EN-GJS-450-10

|

|

Weight

|

1Kg-10Kg

|

|

Manufacturing Process

|

Shell moulding casting, Surface treatment, Inspection

|

|

Casting tolerance

|

ISO8062 ISO2768

|

|

Inspection items and methods

|

Chemical composition: Spectral analysis

Mechanical property: Tensile tester Hardness: Brinell hardness tester Metallography detection: Microscope Inspection: Special tools, Vernier caliper, Depth gauge, Height gauge,etc |

|

Application

|

OEM Valve Accessory

|

OEM / ODM request is very welcome!

Related Products

Production Process

The castings of handwheel are manufactured by shell moulding process. Thus, the large-scale, elaborate and high quality production is realized. Then through efficient machining and rigorous inspection, OEM valve series products would be eventually obtained with good surface quality, high dimensional accuracy, precise weight and optimal comprehensive performance cost ratio.

Before product development, we will evaluate and highlight the technical requirements of the handwheel, including: material, surface treatment, hardness, weight, important technical requests and customer’s special requests. Meanwhile, we will establish files for each customer, including: technical documents, communication records and the time of technique requests changes, this will help us to provide guarantee for product inspection.

Inspection

We have complete testing instruments and quality control means, thus we can control the quality of products from raw materials to finished products timely and effectively. Our commonly used inspection equipment includes: Spectral analyzer, Tensile tester, Hardness tester, Microscope, Roughness tester, CMM, Projector and other gauges and tools.

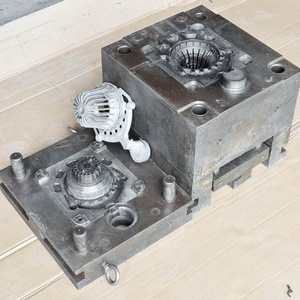

Molds

Mold Development

Mold is the key to producing castings, we have our own mold workshop and mold design engineer, we can ensure the mold development and the rigor of production, manufacturability and the rapidity of mold development, thus we can provide the best guarantee of product development.

Product Packaging

Hot Searches