- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m*2.3m(2.3m

-

Weight:

-

1.38 t/single trough

-

product name:

-

Flotation Separator Gold Flotation Machine For Sale

-

Application:

-

Hematite ore,gold ore ,iron ore,copper ore

-

Capacity:

-

Refer to different specifications

-

Material:

-

Chrome steel,manganese steel

-

Installation:

-

We dispatch engineer to guide

-

Effective cubage(m3):

-

0.35-5.8

-

Keywords:

-

flotation machine,flotation cells

-

Feeding size:

-

200 mesh

-

Color:

-

as request

-

Certification:

-

CE & ISO9001-2008

Quick Details

-

Production Capacity:

-

0.6-1.6

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HengXing

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m*2.3m(2.3m

-

Weight:

-

1.38 t/single trough

-

product name:

-

Flotation Separator Gold Flotation Machine For Sale

-

Application:

-

Hematite ore,gold ore ,iron ore,copper ore

-

Capacity:

-

Refer to different specifications

-

Material:

-

Chrome steel,manganese steel

-

Installation:

-

We dispatch engineer to guide

-

Effective cubage(m3):

-

0.35-5.8

-

Keywords:

-

flotation machine,flotation cells

-

Feeding size:

-

200 mesh

-

Color:

-

as request

-

Certification:

-

CE & ISO9001-2008

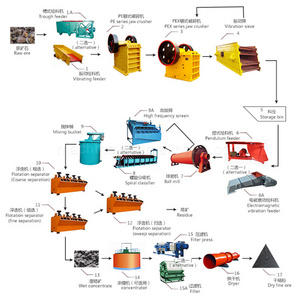

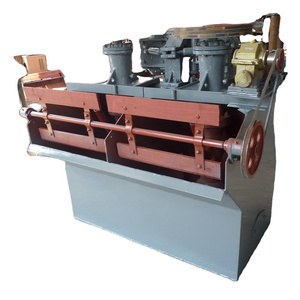

Mining Ore Concentration Plant Flotation Separator Gold Flotation Machine For Sale

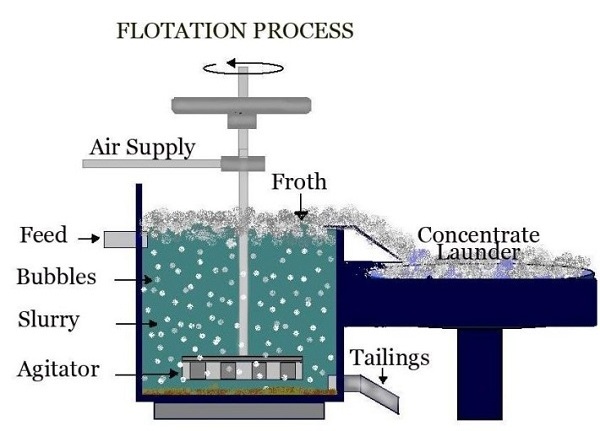

Flotation machine, also known as flotation cell, flotation-cell, is mineral processing equipment relying on buoyancy force, is also one of the most important ore flotation equipment in the flotation separation process. Especially, flotation separator is used most in the separation of non-metallic minerals.

The structure device of flotation machine: This machine is mainly composed of the slurry tank, mixing device, inflatable device, discharge mineralized bubble device, motor and other components.

The role of the Flotation machine for lead zinc ore flotation separating :

In the flotation reagent effect, bubbles and hydrophobic mineral particles contacts, mine mineralized bubbles floating on the pulp surface formed bubble layer. The foam products is scraped by the scraper, slurry in the groove flows through the intermediate chamber to the next slot, the outflow from the last flotation cell is the job of the tailings. In the conduct of the flotation tank can be divided into three areas: (1) mixing and inflatable district is located in the lowest part of the tank nearby impeller. The good mixing of the pulp and the air in this area, it is thrown by the rotation of the impeller. But because this area is stirred strongly, so it is only suitable to aeration and stirring, not conducive to the ore particles to the bubble adhered.

(2) separation zone tank located in central Part, and floating minerals can be can be attached to air bubbles to float, gangue lowered and discharged through the gate.

(3) bubbles area pper area is located in the tank. This area gathered number of mineralized foam, this is the secondary enrichment.

Lead zinc flotation separating process:

The flotation-cell is mainly used to select copper, zinc, lead, nickel, gold and other non-ferrous metals. The flotation plant also can be used for the roughing and selection of ferrous metals and metalloid. In the process of flotation separation, the ups and downs of minerals almost have nothing to do with the mineral density. All those minerals that have high affinity with water or easy to be wet are hard to attach to the bubbles and float upwards, while those have small affinity with water or hard to be wet are easy to float upwards. Like other ore dressing methods, the flotation separation needs to do a good job in selecting the materials before separating, namely the ore needs to be ground and classified so as to achieve the suitable concentration and fineness for the separating at first.

Flotation machine structure:

The structure of flotation machine: this machine is mainly composed of pulp chute, mixing device, air charging system, mineralized froth discharging device and electro motor.

(1) Pulp chute: It has pulp feeding mouth and the gate device used for adjusting the liquid level and it is mainly composed of mainly composed by the chute body which is melt by the steel board and gate melt by the steel board and steel rod.

(2) Mixing device: It is mainly used for mixing the pulp in order to prevent the mineral sand to deposit on the chute, and it is mainly composed by the belt wheel, impeller, vertical shaft and the impeller is made of the anti-abrasion rubber.

XJK Series Flotation machine :

|

Model |

XJK-0.35(3A) |

XJK-0.62(4A) |

XJK-1.1(5A) |

XJK-2.8(6A) |

XJK-5.8(7A) |

||

|

Effective cubage(m3) |

0.35 |

0.62 |

1.1 |

2.8 |

5.8 |

||

|

Production capacity(m3 /min) |

0.18-0.4 |

0.3-0.9 |

0.6-1.6 |

1.5-3.5 |

3-7 |

||

|

Rotation speed(r/min) |

470 |

400 |

330 |

280 |

240 |

||

|

Blade diameter(mm) |

300 |

350 |

500 |

600 |

750 |

||

|

Motor |

Model |

Rotor |

Y90L-4 |

Y100L2-4 |

Y132M2-6 |

Y160L-6 |

Y200L2-6(Y225M-6) |

|

Scraping plate |

Y90S-4 |

Y90S-4 |

Y90S-4 |

Y90S-4 |

Y90L-4 |

||

|

Power(kw) |

Blade Motor |

1.5 |

3 |

5.5 |

11 |

22(30) |

|

|

Scraping plate Motor |

1.1 |

1.1 |

1.1 |

1.1 |

1.5 |

||

|

Weight(t/single trough) |

0.43 |

0.86 |

1.38 |

2.33 |

3.533 |

||

SF Series flotation machine :

|

Model |

SF0.37 |

SF0.7 |

SF1.2 |

SF2.8 |

SF4 |

|

|

Trough capacity(m 3 ) |

0.37 |

0.7 |

1.2 |

2.8 |

4 |

|

|

Blade diameter(mm) |

300 |

350 |

450 |

550 |

650 |

|

|

Production capacity(m 3 /min) |

0.2-0.4 |

0.3-0.9 |

0.6-1.2 |

1.5-3.5 |

0.5-4 |

|

|

Blade rotation speed(m3/min) |

352 |

400 |

312 |

268 |

238 |

|

|

Motor |

Model |

Y90L-4 |

Y100L2-4 |

Y132M2-6 |

Y160L-6 |

Y180L-6 |

|

Y90S-4 |

Y90S-4 |

Y90S-4 |

Y90S-4 |

Y90L-4 |

||

|

Power(kw) |

1.5 |

3 |

5.5 |

11 |

15 |

|

|

1.1 |

1.1 |

1.1 |

1.1 |

1.5 |

||

|

Dimensions(mm) |

700*700

|

900*820

|

1100*1100

|

1700*1600

|

1850*2050

|

|

|

Single trough weight(kg) |

468 |

600 |

1373 |

2338 |

2660 |

|

Inside parts of the flotation machine :

Flotation cells from stock :

Lead Zinc Flotation Machine Separating Plant:

The flotation machine will start delivery in 30 days after payment. It will be packed in the export standard container, its main motor and spare parts will be put in the water-proof and sealed wooden case.

We promise that the flotation machine will be shipped to you timely and safely.

Hengxing equipment can provide turkey service for customers, such as engineering consultation, engineering design, equipment manufacturing, packing & transportation, installation & commissioning personnel training etc.

About Spare Parts

Hengxing equipment will be dedicated to provide our customers with genuine spare parts with high quality. With our technological advice, the life cycle of your machine can be prolonged and sustained significantly with high effectiveness.

About Training

Hengxing equipemnt could offer excellent facilities and comfortable environment and training services to different customers. The training should include product training, safety training, operation training, maintenance know-how, technical know-how training, and regulations training, etc. All of the training is customized to fulfill every customer’s expectations. Training programs can be conducted in our workshop, or at customer’s site.

About Installation and Commissioning

Hengxing equipment are able to guide the overall installation of whole set production line, including crushing production line and cement equipment production line, etc., which will allow you to start the normal operation of equipment immediately. After installation,we will make inspection of the whole machine commissioning and operation condition and provide you testing data report of installation.