- Product Details

- {{item.text}}

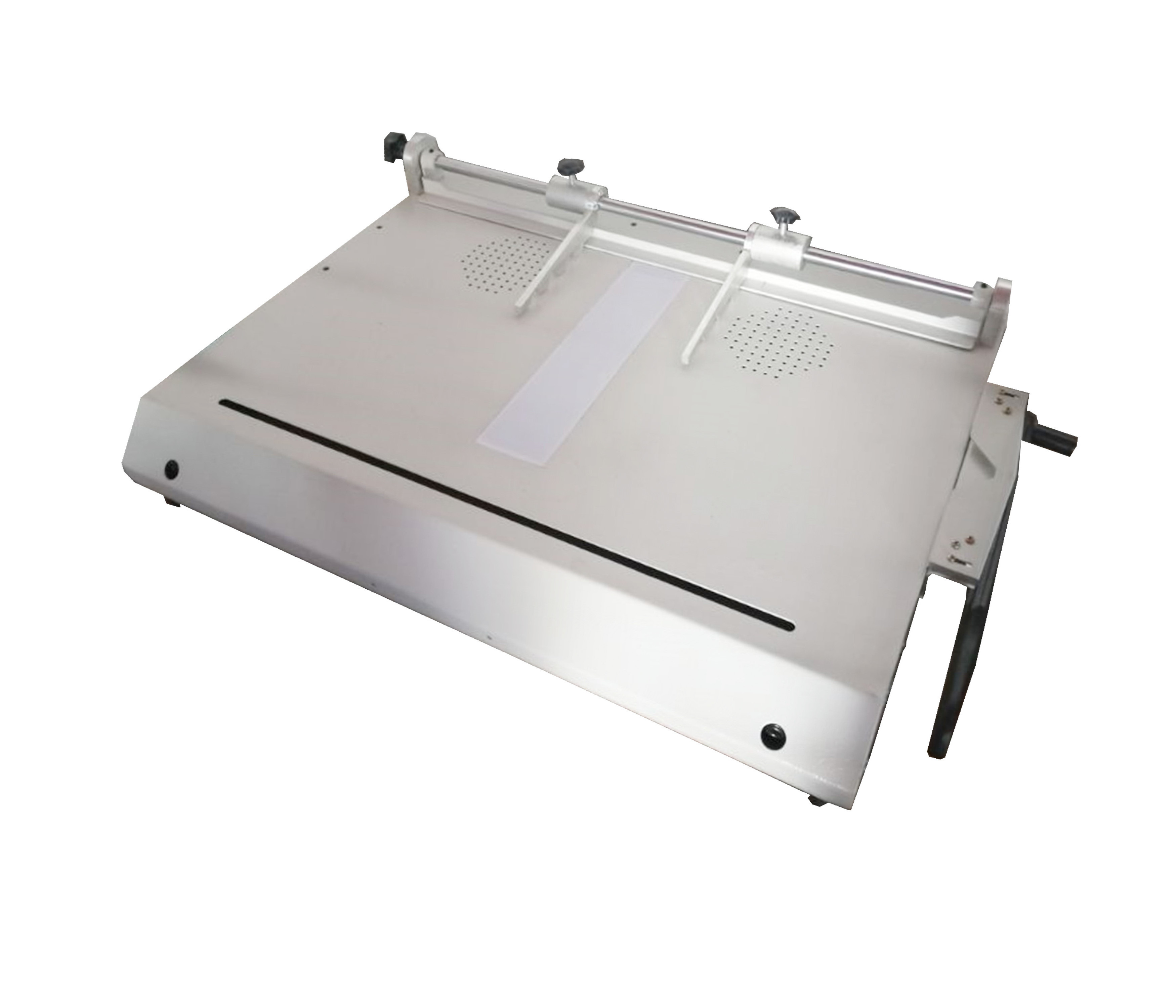

Quick Details

-

Voltage:

-

220V/3A

-

Dimension(L*W*H):

-

1100*700*230mm

-

Weight:

-

48.5 KG

-

Max cover area::

-

980*630mm

-

Cardboard thickness::

-

0.5-6mm

-

Finished book cover size, max::

-

A3 format(binding the long side)

-

Positioning mode::

-

central positioning

-

Reflection and refraction device::

-

Available

-

negtive pressure absorbing device::

-

Available

-

Power supply::

-

220V/3A

-

Dimensions::

-

1100*700*230mm

-

GW.::

-

48.5KGS

Quick Details

-

Type:

-

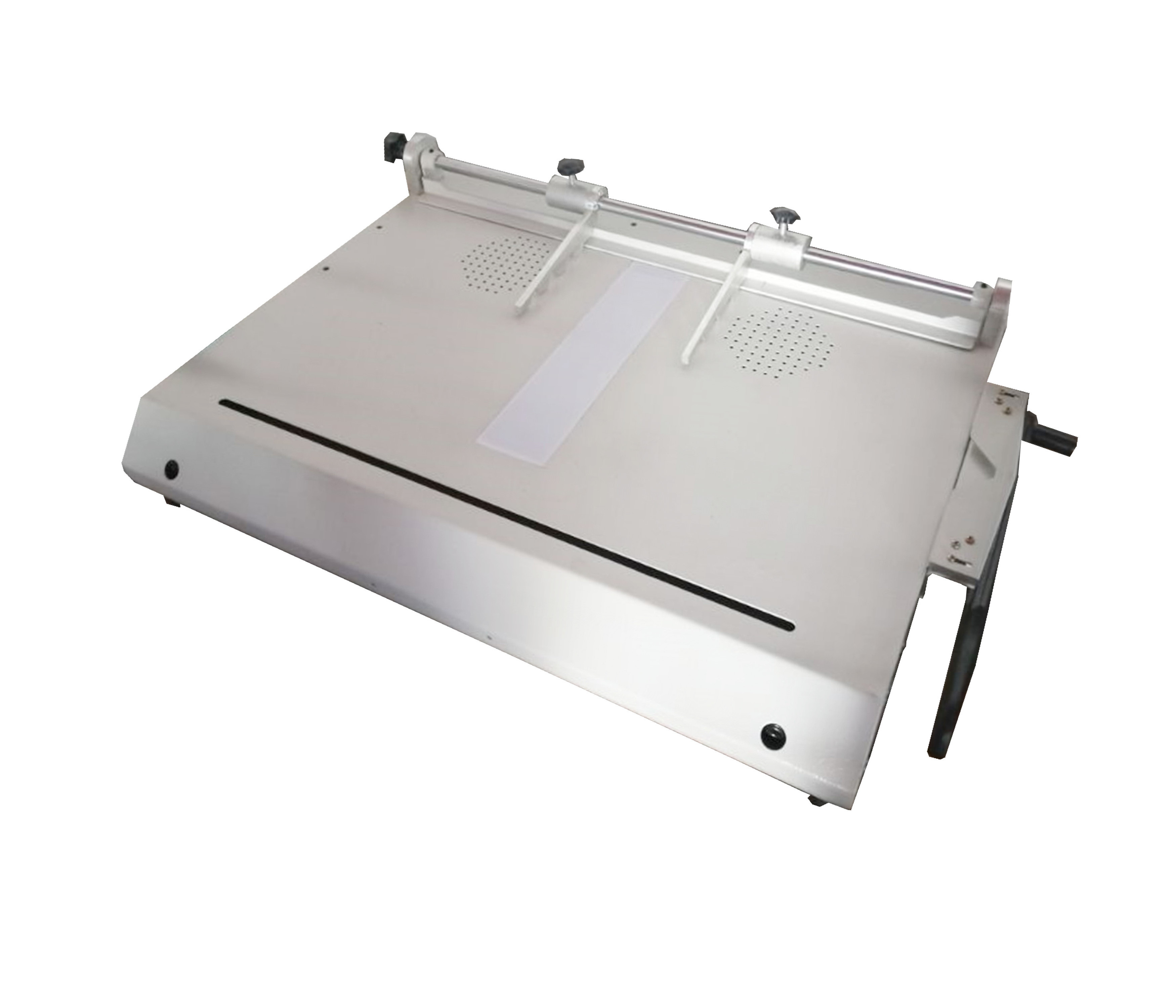

hard cover maker

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Taurus

-

Voltage:

-

220V/3A

-

Dimension(L*W*H):

-

1100*700*230mm

-

Weight:

-

48.5 KG

-

Max cover area::

-

980*630mm

-

Cardboard thickness::

-

0.5-6mm

-

Finished book cover size, max::

-

A3 format(binding the long side)

-

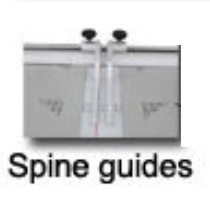

Positioning mode::

-

central positioning

-

Reflection and refraction device::

-

Available

-

negtive pressure absorbing device::

-

Available

-

Power supply::

-

220V/3A

-

Dimensions::

-

1100*700*230mm

-

GW.::

-

48.5KGS

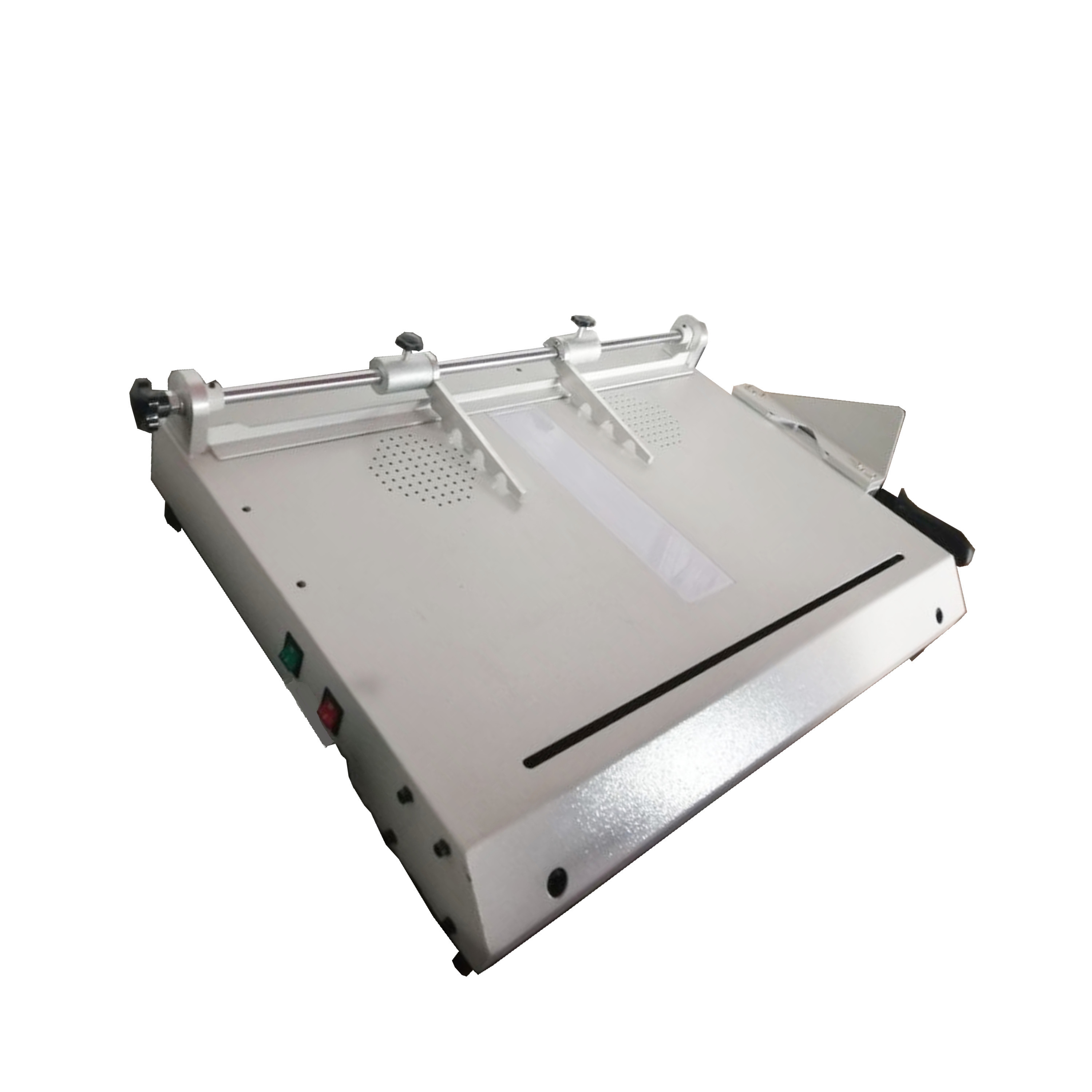

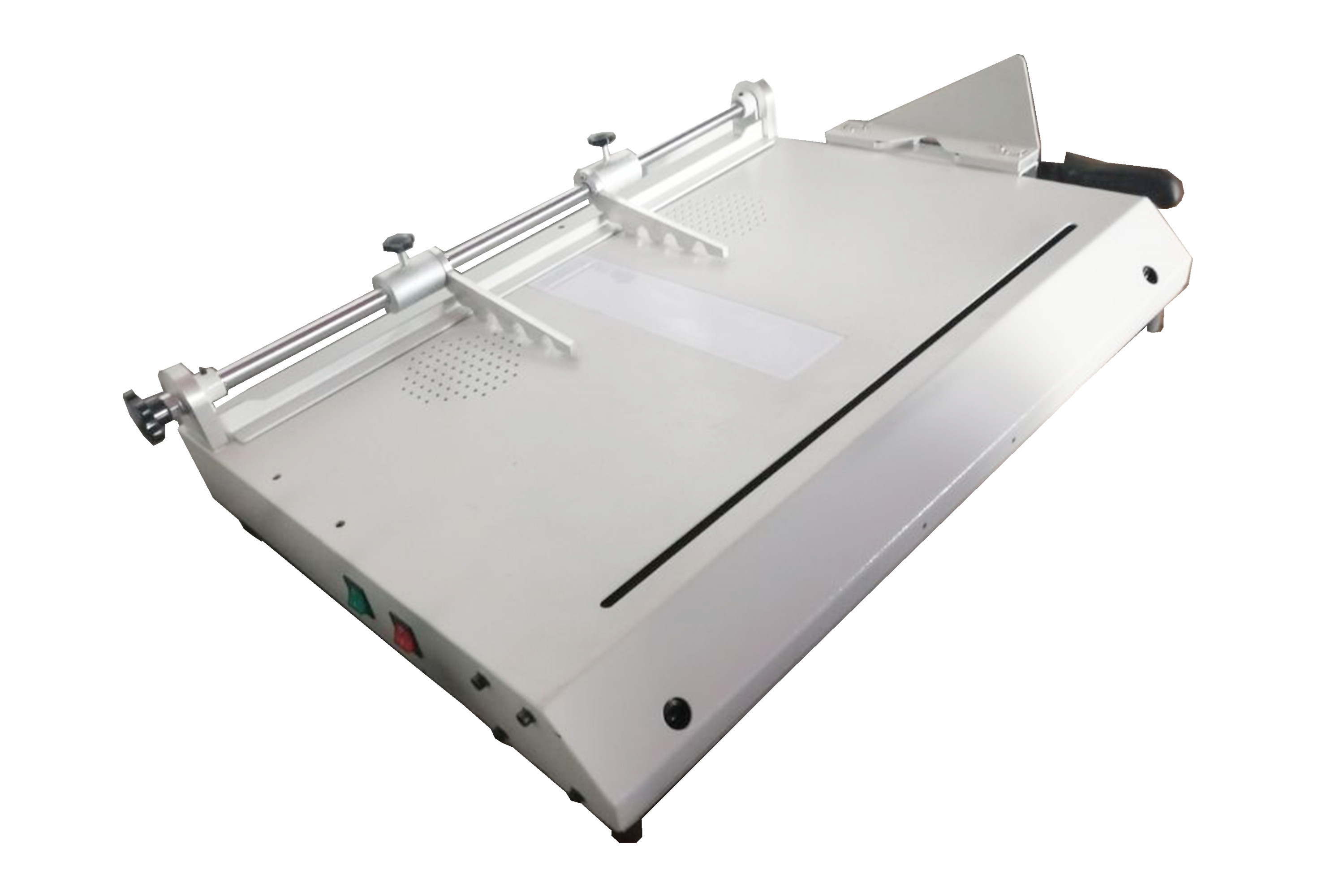

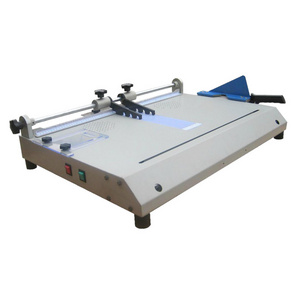

Suitable for making hard cover books, CD and DVD boxes, ring binders, photo albums, restaurant menus, etc.

You can produce high-quality books in a wide variety of formats within a short time.

Cover, cardboard of the cover and cardboard of spine are located accurately; the thickness of cardboard can be 0.5-6 mm.

How to make hard cover (case book):

Step One: Insert your chipboard or card stock in the rotating arm of the machine and turn on the machine light.

Step Two: Print your image on inkjet printable back adhesive plastic sheet (If you don't have back adhesive plastic sheet, you can

also use double-sided adhesive tape and stick on image). You can optionally laminate the sheet by using bopp film for protection.

Peel off the pressure sensitive backing and lay the sheet face down on the machine table.

Step Three: Rotate the machine arm, which lowers the card stock onto the plastic sheet in the precise position. Trim the corners

at 45 degrees and fold over the four edges.

Step Four: Run the cover through the laminator to cold pressure press out any paper bubbles or wrinkles. Your hard cover is now

ready for binding!

Step Five: Place a hard cover fly-sheet on each side of your book block. Bind the book on a binding machine and then peel out the

backing from the fly sheets. The inside chipboard is now covered. If you wish, you can pre-print on the inside of the cover

fly-sheets to give your book that extra professional touch.

You can produce high-quality books in a wide variety of formats within a short time.

Cover, cardboard of the cover and cardboard of spine are located accurately; the thickness of cardboard can be 0.5-6 mm.

How to make hard cover (case book):

Step One: Insert your chipboard or card stock in the rotating arm of the machine and turn on the machine light.

Step Two: Print your image on inkjet printable back adhesive plastic sheet (If you don't have back adhesive plastic sheet, you can

also use double-sided adhesive tape and stick on image). You can optionally laminate the sheet by using bopp film for protection.

Peel off the pressure sensitive backing and lay the sheet face down on the machine table.

Step Three: Rotate the machine arm, which lowers the card stock onto the plastic sheet in the precise position. Trim the corners

at 45 degrees and fold over the four edges.

Step Four: Run the cover through the laminator to cold pressure press out any paper bubbles or wrinkles. Your hard cover is now

ready for binding!

Step Five: Place a hard cover fly-sheet on each side of your book block. Bind the book on a binding machine and then peel out the

backing from the fly sheets. The inside chipboard is now covered. If you wish, you can pre-print on the inside of the cover

fly-sheets to give your book that extra professional touch.

|

Max cover area:

|

980*630mm

|

|

|

|

Cardboard thickness:

|

0.5-6mm

|

|

|

|

Finished book cover size, max:

|

A3 format(binding the long side)

|

|

|

|

Positioning mode:

|

central positioning

|

|

|

|

Reflection and refraction device:

|

Available

|

|

|

|

negtive pressure absorbing device:

|

Available

|

|

|

|

Power supply:

|

220V/3A

|

|

|

|

Dimensions:

|

1100*700*230mm

|

|

|

|

GW.:

|

48.5KGS

|

|

|

1.How can I get sample to check your quality?

We have free sample available for all dear customers,you just have to pay the cost of freight or air courier.If you place order to

us,we can deduct the cost from the total order amount.

2.If I don't know how to operate,how can I get installation and training?

We have an experienced service group,our engineer can go to your factory to give approx.1 week.You have to cover all the

visa,flight ticket expense and provide our engineer accommodation and allowance $80/day.

3.If there is any problem on machine,how can I solve it?

First of all,we have online service,after submitting and problem we will come up with solution,if you can solve it yourself we

will give you procedure step by step teach you solve it,by msg,pic,voice,or video talk.Normally we are good at video talk,and it

is most successful method.If any electronic parts in problem which is occured itself(not improper operation),within one year

warranty we will send new parts for replacement.You just cover the cost of frieght or air lift.

4.What's the lead time and lead term?

Leading time is 30 days after rceipt of 30%$ deposit,balance paid before delivery.

We have free sample available for all dear customers,you just have to pay the cost of freight or air courier.If you place order to

us,we can deduct the cost from the total order amount.

2.If I don't know how to operate,how can I get installation and training?

We have an experienced service group,our engineer can go to your factory to give approx.1 week.You have to cover all the

visa,flight ticket expense and provide our engineer accommodation and allowance $80/day.

3.If there is any problem on machine,how can I solve it?

First of all,we have online service,after submitting and problem we will come up with solution,if you can solve it yourself we

will give you procedure step by step teach you solve it,by msg,pic,voice,or video talk.Normally we are good at video talk,and it

is most successful method.If any electronic parts in problem which is occured itself(not improper operation),within one year

warranty we will send new parts for replacement.You just cover the cost of frieght or air lift.

4.What's the lead time and lead term?

Leading time is 30 days after rceipt of 30%$ deposit,balance paid before delivery.

Hot Searches