- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Non-required power

-

Dimension(L*W*H):

-

1360*1360*5230mm (5LL-1200)

-

Weight:

-

600kg

-

Warranty:

-

12 months

-

Product name:

-

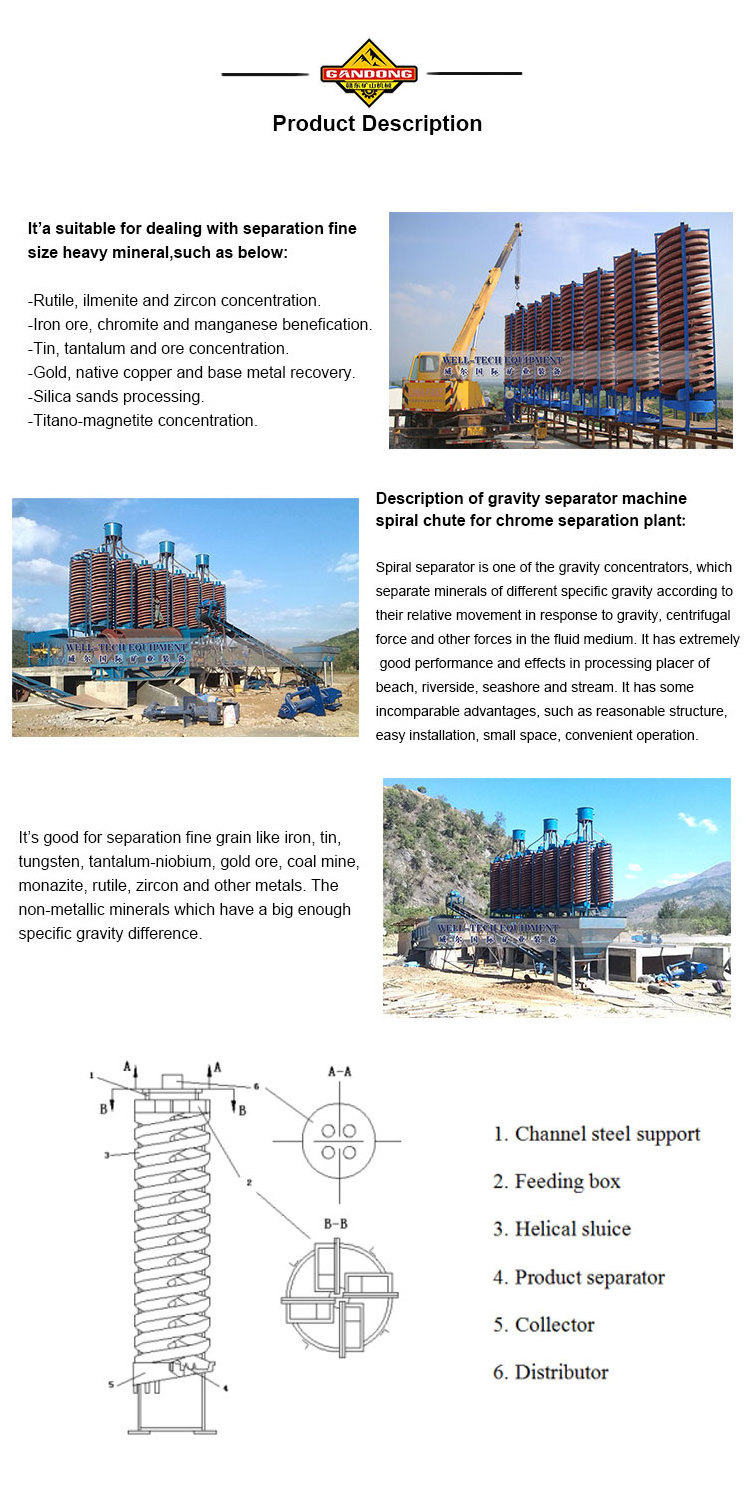

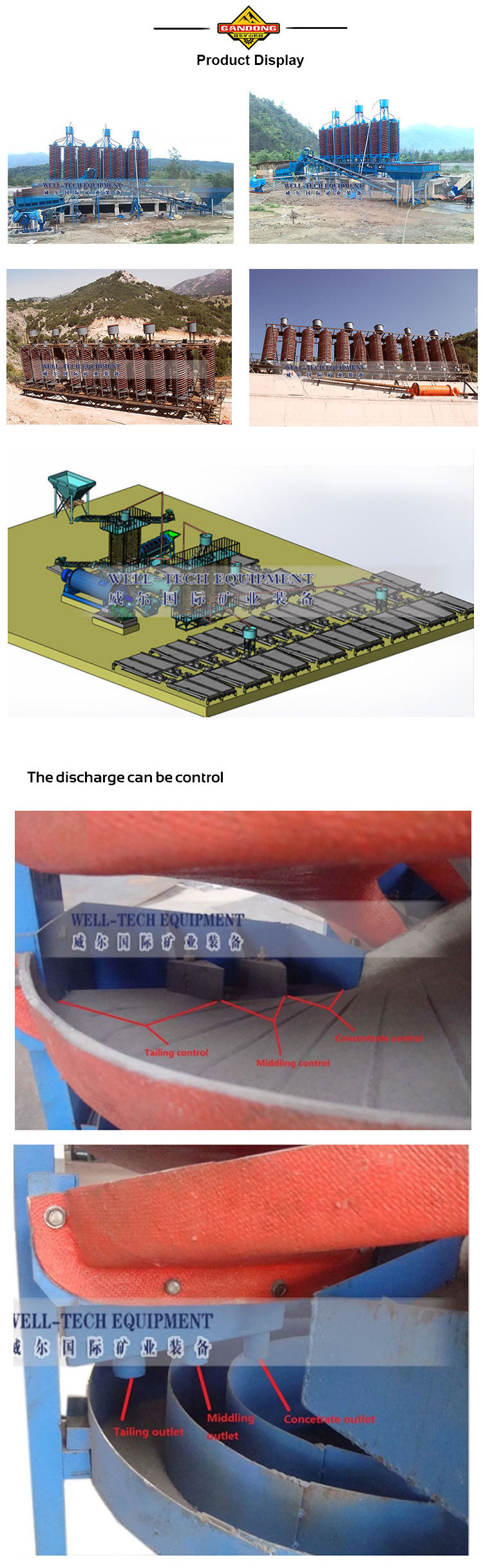

Chrome Ore Concentration Plant Spiral Chute Factory

-

Application:

-

Ore Concentration

-

Model availabe:

-

5LL-2000/5LL-1500/5LL-1200/5LL-900/5LL-600/5LL-400

-

Capacity:

-

Depends on model

-

Feeding density:

-

25-55%

-

Feeding sizes:

-

0.02-2.00mm

-

Starts:

-

2/3/4

-

Flowchart design:

-

Professional enginner service for you

-

Spare parts:

-

Supply

-

whole line machine:

-

supply

-

Certification:

-

ISO9001:2008, SGS

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Well-tech

-

Voltage:

-

Non-required power

-

Dimension(L*W*H):

-

1360*1360*5230mm (5LL-1200)

-

Weight:

-

600kg

-

Warranty:

-

12 months

-

Product name:

-

Chrome Ore Concentration Plant Spiral Chute Factory

-

Application:

-

Ore Concentration

-

Model availabe:

-

5LL-2000/5LL-1500/5LL-1200/5LL-900/5LL-600/5LL-400

-

Capacity:

-

Depends on model

-

Feeding density:

-

25-55%

-

Feeding sizes:

-

0.02-2.00mm

-

Starts:

-

2/3/4

-

Flowchart design:

-

Professional enginner service for you

-

Spare parts:

-

Supply

-

whole line machine:

-

supply

-

Certification:

-

ISO9001:2008, SGS

Beneficiation ore sorting lead zinc ore,tin,hematite,limonite use gravity separator machine spiral chute shaking table

Spiral concentrator Technical Specifications

|

Specification |

5LL-2000 |

5LL-1500 |

5LL-1200 |

5LL-900 |

5LL-600 |

5LL-400 |

|

|

Spiral Diameter(mm) |

2000 |

1500 |

1200 |

900 |

600 |

400 |

|

|

Spiral Pitch(mm) |

1200 |

540/680/900 |

720 /540 |

675/540 /405 |

400 |

240/180 |

|

|

Lateral Obliquity |

9° |

9° |

9° |

9° |

9° |

9° |

|

|

Starts |

3 |

4 |

4 |

4 |

2 |

2 |

|

|

Feeding Sizes(mm) |

2.00-0.04 |

0.8-0.037 |

0.3-0.03 |

0.3-0.03 |

0.2-0.02 |

0.2-0.02 |

|

|

Feeding Density (%) |

30-55 |

30-60 |

25-35 |

25-55 |

25-55 |

25-55 |

|

|

Capacity(t/h) |

7-10 |

6-8 |

4-6 |

2-3 |

0.4-0.8 |

0.15-0.2 |

|

|

Dimension

|

Length |

2120 |

1600 |

1360 |

1060 |

700 |

460 |

|

Width |

2120 |

1600 |

1360 |

1060 |

700 |

460 |

|

|

Height |

5600 |

5300 |

5230 |

4000 |

2600 |

1500 |

|

|

Weight (kg ) |

900 |

800 |

600 |

400 |

150 |

50 |

|

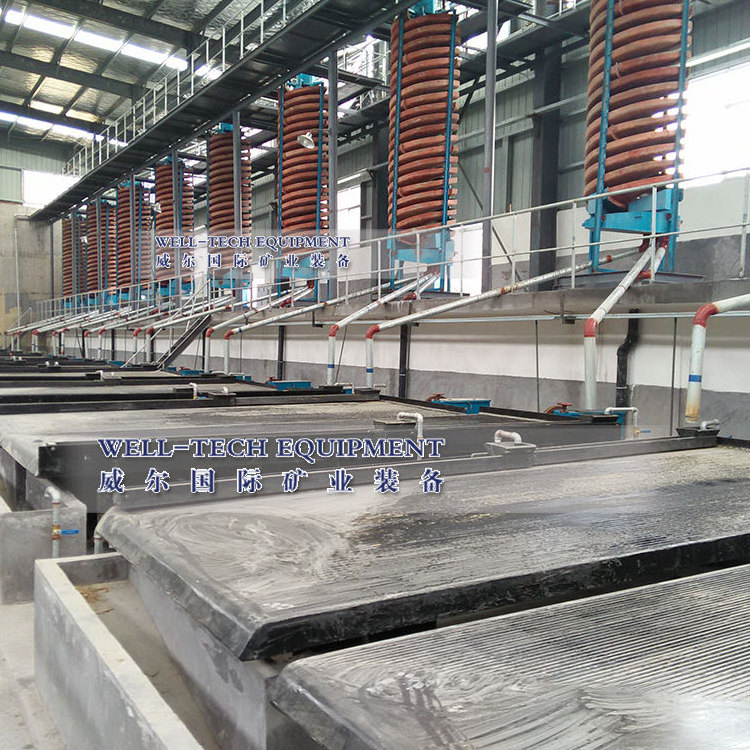

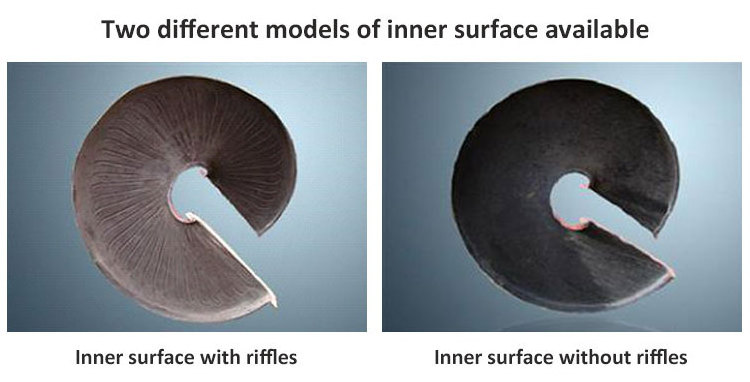

Working principle

Spiral Chute is working under the the force of water flow, gravity, inertial centrifuge and friction. Slurry is pumped to the top of the spiral , and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles arecarried with the bulk of the water towards the outside of the spiral , while particles with the greatest density migrate towards the inside of the spiral.

Mineral processing line case show

Our goal is to provide customers with one stop service in the field of mining, including the minerals in the mineral analysis, mineral processing test, engineering design, equipment production, equipment installation, equipment debugging and of technical training etc integrated services, through the provision of our perfect services to solve all customer's problem from his investment to his return.

Jiangxi Well-tech International Mining Equipment Co.,Ltd. (Gandong Mining Equipment) is a large mineral processing service company specialized in designing, manufacturing, installing and debugging of mining equipment as well as providing flow sheet design and course training of mineral processing.

Our company covers an area of 48,000 square meters, the workshop covers 20,000 square meters, we have various large modernized machinery process facilities, professional engineering team and installation team.

Now our company is the largest manufacturer and exporter of gravity dressing equipment in China.

Pre-Sales Service

Inquiry and consulting support.

Sample testing support.View our Factory.

After-Sales Service

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.