- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

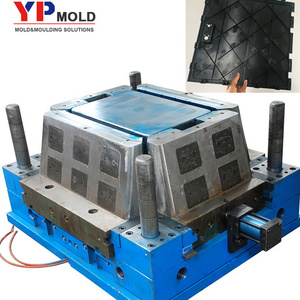

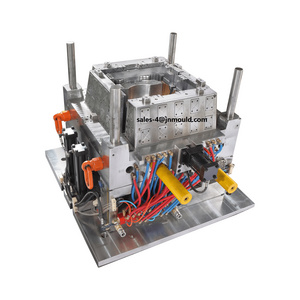

vacuum cleaner mould

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YF mould

-

Model Number:

-

vacuum cleaner mould

plastic air cooler machine mould

plastic injection air cooler mould

Mould Details

1.Cavity :Single& double

2. Mold Material: P20,718,etc

3. Runner: hot runner,cold runner

4. Delivery time: 90 days

5. Design software :UG, PROE, CAD

6. Mould base: home made mould base

7. Mould life: above 500,000 shots

8. Package: wooden cases or according to customers requirement.

1, Mould base is use of LKM frame, and HASCO standard frame, all components are with DME or

HASCO standard.

2, We have a wide useage of mold steel, both local and improted,

45#, 50#, P20, H13, 718&738H, 2738,2344, S136, from ASSAB, DAIDO, THYSSEN, FINKL,etc.

heat treatment to HRD 48~52 HRC, nitried all sliders and inserts, use Berylium Copper in corners

to improve cooling.

3, We supply full set of 3D mold drawing and details layout.

4, We make all kinds of mold, big size up to 15 Tons, smaller size up to 0.5mm on plastics; We make cold runner mold, hot runner mold(Husky,Mold maser,Synventive,DME and YUDO), 3-plate mold, over mold, insert mold, reverse ejection mold, gas asistance mold, etc. Our engineer and technican are always keep studying and get more and more experienced and professional on mold making skills.

5, We have a wide usage on plastic material, especially for those may cause worse deformation,

bad filling, worse part surface, we have our ways to control the mold to have better parts.

6, We ensure the mold life to customers, we provide steel and material conformity, certicate to customers.

7, Our advanced equipment and high effective mangement give customers quick lead time,

sometimes we only take 10 days to finish prototype molds.

Our Service:

-Virgin market car parts mould making

-After market car parts mould making

-Gas-assist injection mould design and mould making

-High gloss polishing mould making

-Customer design service

-Prototyping

-Mould making

-Manufacturing process control

-Mould flow analysis service avaiable

-Customer moulding assembly

-Cold mould runner and hot mould runner

Our Company Flow Chart

|

1.Enquiry |

Our customers send drawing or 3D with detail information to us. |

|

↓ |

|

|

2. Quote |

According to the details,we make an offer. |

|

3. Negotiation |

The material,delivery time,payment ,price and ect. |

|

↓ |

|

|

4.Place an order |

Contract Examing&Commenting |

|

↓ |

|

|

5.Mold Design |

Mold Structure Drawing and Auditing. |

|

↓ |

|

|

6.Mold Make |

Before making,we send design to customer to approve. |

|

↓ |

|

|

7.Test Sample |

We send the test sample to customer until meet customers’requests. |

|

↓ |

|

|

8.Delivery |

Delivery by sea or according to customers’. |

| What are our advantages at custom plastic injection mould |

| 1.With strict Quality Management system,make sure you make produce 500,000 to 1,000,000 shots ,with long life. |

| 2. With a perfect mold design and mold making standard criteri |

| 3.Familiar with HASCO / MISUMI / Jinhong standard parts, specializes in designing HASCO / musumi / Jinhong standard export mode. |

| 4,With all the equipment needed for precision molds, Sodick wire walking, High-speed CNC(Exeron), EDM (Exeron) , surface grinders, milling machines, projectors (Mitutoyo) , 2.5 million testing equipment(Mitutoyo), high-speed injection molding machine(JSW). |

| 5.Machining precision:EDM Precision 0.001mm,Wire EDM Precision 0.001mm,CNC Precision 0.002mm,Grinding Machine Precision 0.001mm. |

| 6.About 30-45 days after getting final confirmation. |

| 7.Provid perfect service ,you can chat or call me within 24hours ,we will react at first time. |

Skype:chinamould-sky

Whatsapp:008613606822504

QQ/Wechat:544017082

Packaging :wooden case packaging or according to your request

Shipping Port:Ningbo or Shanghai