<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U-TECH MACHINE

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight:

-

2000 KG

-

Product name:

-

Liquid Filling Machinery Water Bottling Machine

-

Model:

-

CGF 14-12-5

-

Capacity:

-

5000BPH

-

Filling range:

-

200-2000ml

-

Function:

-

Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

Stainless Steel 304

-

Usage:

-

Filling Material

-

Filling material:

-

Flowing Liquid

-

Certification:

-

CE SGS

Quick Details

-

Machinery Capacity:

-

5000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U-TECH MACHINE

-

Dimension(L*W*H):

-

2400x1650x2500mm

-

Weight:

-

2000 KG

-

Product name:

-

Liquid Filling Machinery Water Bottling Machine

-

Model:

-

CGF 14-12-5

-

Capacity:

-

5000BPH

-

Filling range:

-

200-2000ml

-

Function:

-

Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

Stainless Steel 304

-

Usage:

-

Filling Material

-

Filling material:

-

Flowing Liquid

-

Certification:

-

CE SGS

Description

This CGF Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

Technical Parameters

|

Model

|

CGF14-12-5

|

|

Capacity

|

5000PBH

|

|

Washing heads

|

14

|

|

Filling heads

|

12

|

|

Capping heads

|

5

|

|

suitable bottle

|

PET bottle,plastic bottle

|

|

Diameter of bottle

|

55-110mm

|

|

Height of bottle

|

150-310mm

|

|

Suitable cap

|

Plastic screw cap

|

|

Weight

|

2000kg

|

|

Main motor power

|

1.5kw

|

Machine Details

Washing heads

Filling heads

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

Capping heads

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

Main Features

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Control System

|

S/N

|

Name

|

Brand

|

Country

|

|

1

|

Main motor

|

ABB

|

Switzerland

|

|

2

|

Inverter

|

MITSUBISHI

|

Japan

|

|

3

|

PLC

|

OMRON

|

Japan

|

|

4

|

Touch screen

|

MITSUBISHI

|

Japan

|

|

5

|

Contactor

|

SCHNEIDER

|

France

|

|

6

|

Thermo- relay

|

SCHNEIDER

|

France

|

|

7

|

Air-break switch

|

SCHNEIDER

|

France

|

|

8

|

Proximity switch

|

TURCK

|

USA

|

|

9

|

Photoelectric switch

|

BANNER

|

USA

|

|

10

|

Air circuit system

|

SMC

|

Japan

|

|

11

|

Water pump

|

Southern

|

China

|

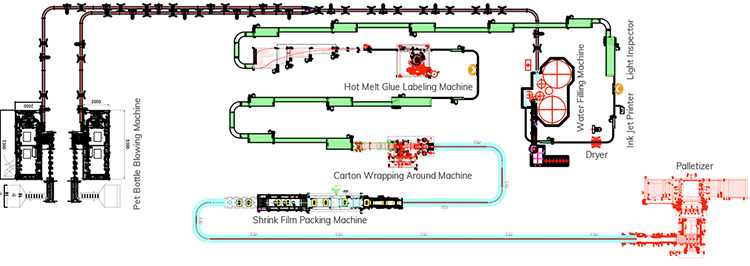

Related Products

Drinking Water Treatment Equipment

Process: Spring-raw water booster pump, mechanical filter, precision filter, active carbon filter, sodium exchanger, RO machine / hollow fiber ultrafiltration device, Store tank, UV sterilizer, ozone generator and other equipment. It can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the water. This water treatment equipment can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh water standards, even that of standard of mineral water.

Automatic bottle blow molding machine

The pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has various cavities and the maximum capacity of the products is 20L. It can blow bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers etc. Which is made of plastic of crystalline type, such as PET and PP etc.

Dryer

Using high pressure air ventilation, so that high-speed air flow ejected from a slit, the remaining drops of water bottles as much as possible the body blow it away. Inclination of the slit so that the entire side of the bottle can be high-speed air-blown. The bottle dryer consists of the high pressure air fan, pressure tank, inflatable tube, rack, control devices, and other components.

Laser printer

Laser marking machines handle nearly every industrial marking and DPM (Direct Part Marking) task. Metals, plastics, ceramics, glass etc. are processed efficiently and contact-free. All desired contents are applied repeatedly accurate and reliably: 2D, DMC and alphanumeric codes, simple serial numbers, complex logos, graphics, structures. Depending on the material and application task, the process is laser marking, engraving or deep engraving.

Automatic Sleeve labeling Machine

1.The hot sale bottle neck automatic heat shrink sleeve label machine is unwound evenly from the reel via feed roller and conveyed to the cutting unit via the sleeve supply unit.hot sale bottle neck automatic heat shrink sleeve label machine .

2. The hot sale bottle neck automatic heat shrink sleeve label machine sleeve is opened by pulling it over a mandrel, a servomotor-controlled cutter cuts the sleeves exactly to the set length. After that, the under-brush pulls the sleeves over the container.

3. Depending on the container shape and the sleeve size, an optional positioning brush moves the sleeve to the desired position. As a result, each sleeve is in perfect position and cannot slip.

4.Optional hot-air nozzles shrink and pre-position the sleeves.After that, the sleeves are shaped perfectly around the container contour in a steam or hot-air tunnel.

2. The hot sale bottle neck automatic heat shrink sleeve label machine sleeve is opened by pulling it over a mandrel, a servomotor-controlled cutter cuts the sleeves exactly to the set length. After that, the under-brush pulls the sleeves over the container.

3. Depending on the container shape and the sleeve size, an optional positioning brush moves the sleeve to the desired position. As a result, each sleeve is in perfect position and cannot slip.

4.Optional hot-air nozzles shrink and pre-position the sleeves.After that, the sleeves are shaped perfectly around the container contour in a steam or hot-air tunnel.

Automatic shrink wrap packing machine

In the packaging machinery industry, the film wrapping machine is the abbreviation of the wrapping film packaging machine, sometimes called the winding machine and the wrapping machine.

Function: It is suitable for the packaging requirements of cargo storage, transportation and mechanical loading and unloading operations. Widely use the packaging cost of products such as foreign trade export, food and beverage, irrigation, paper making, dyes, plastic chemicals, glass ceramics, machine S electric castings, etc., improve production efficiency, and prevent damage of goods during handling, and play Dust, moisture and cleaning.

Function: It is suitable for the packaging requirements of cargo storage, transportation and mechanical loading and unloading operations. Widely use the packaging cost of products such as foreign trade export, food and beverage, irrigation, paper making, dyes, plastic chemicals, glass ceramics, machine S electric castings, etc., improve production efficiency, and prevent damage of goods during handling, and play Dust, moisture and cleaning.

Machine Running Video

About U TECH

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Hot Searches