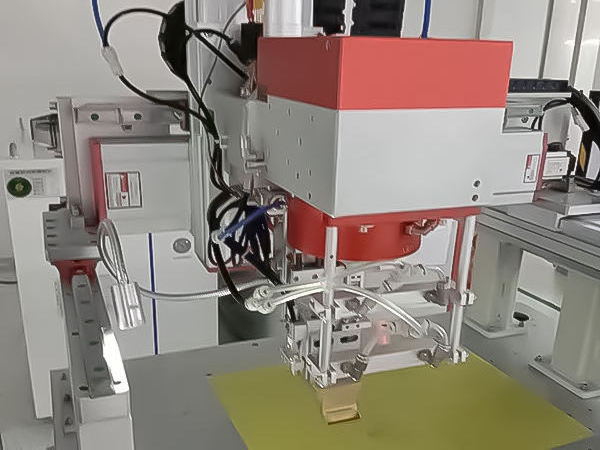

1. Gantry frame;

2. Fiber laser;

3. Galvo welding head;

4. CCD monitor;

5. Welding system host and display;

6. Laser chiller;

7. Servo motor and modules.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MAS-SpotWelder-2000W

-

Place of Origin:

-

Guangdong, China

-

Weight:

-

2000 KG

-

Laser Power:

-

2000W

Quick Details

-

Anode Material:

-

LFP

-

Application:

-

Battery aluminum electrode welding

-

Brand Name:

-

Mason

-

Model Number:

-

MAS-SpotWelder-2000W

-

Place of Origin:

-

Guangdong, China

-

Weight:

-

2000 KG

-

Laser Power:

-

2000W

Product Description

Li ion 18650 Battery Lithium battery PACK laser welding equipment consists of:

The advantages of lithium battery PACK laser welding equipment:

1. Gantry motion structure, large-scale stroke welding range;

2. High photoelectric conversion efficiency, very good beam quality;

3. Adjustable laser power, low power consumption, daily maintenance-free;

4. PC industrial computer, welding numerical control programming system, simple and easy to learn;

5. Support adding CCD visual positioning system, automatic focal length function.

2. High photoelectric conversion efficiency, very good beam quality;

3. Adjustable laser power, low power consumption, daily maintenance-free;

4. PC industrial computer, welding numerical control programming system, simple and easy to learn;

5. Support adding CCD visual positioning system, automatic focal length function.

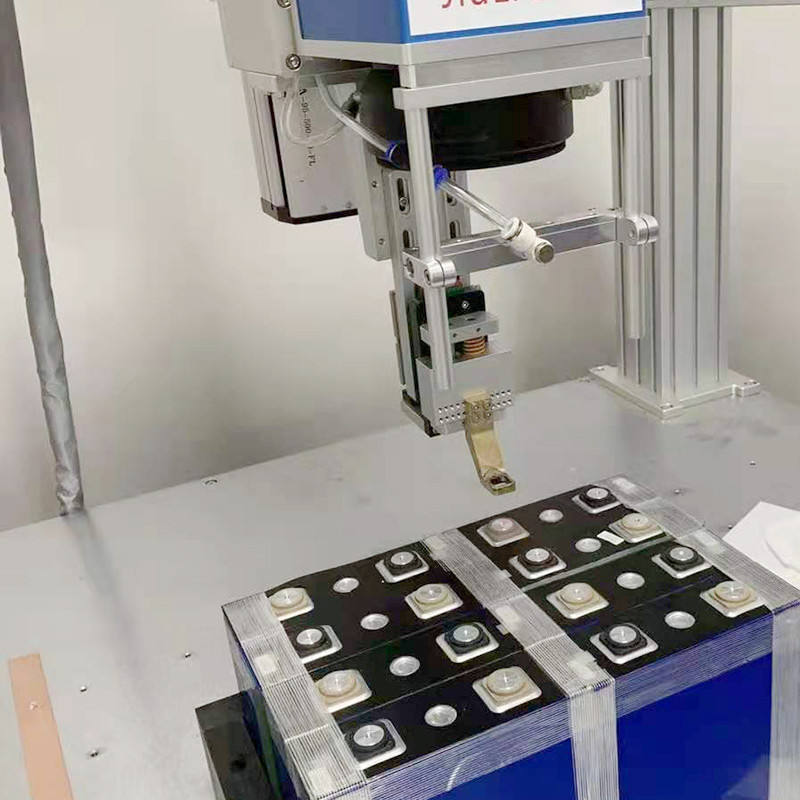

Application areas:

Mainly used in new energy lithium batteries: Busbar welding, rotary stud welding, tab welding, nickel rotary welding,explosion-proof valve welding, shell sealing welding, liquid injection port welding, etc.

At the same time as the energy density of lithium-ion batteries is increasing rapidly, the threshold for safety is also rising.

A good laser welding function can greatly reduce the failure rate of defective products, and the poor quality of lithium-ion

batteries will cause the risk of thermal runaway caused by short circuit.

A good laser welding function can greatly reduce the failure rate of defective products, and the poor quality of lithium-ion

batteries will cause the risk of thermal runaway caused by short circuit.

Advantage

Fiber laser galvanometer welding head:

1. The X and Y axis vibrating lenses are focused by the F-THETA focusing lens group, which can realize a variety of swing

modes;

2. Swing speed: 4000mm/s, range: 100/120mm;

3. The internal structure is completely sealed, which can prevent the optical part from being polluted by dust;

4. It has the characteristics of fast welding speed and high precision. In multi-point welding, the production efficiency is

more advantageous.

modes;

2. Swing speed: 4000mm/s, range: 100/120mm;

3. The internal structure is completely sealed, which can prevent the optical part from being polluted by dust;

4. It has the characteristics of fast welding speed and high precision. In multi-point welding, the production efficiency is

more advantageous.

The third generation single-mode fiber laser generator:

It has higher photoelectric conversion efficiency (>30%), better and more stable beam quality, and stronger anti-high-reflection ability. At the same time, the optimized second-generation optical fiber transmission system is introduced to ensure more stable welding of thick plates. , Precise welding effect.

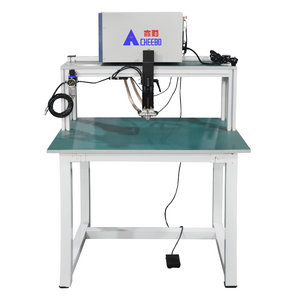

1.6m large gantry platform:

The large range of motion travel is specially designed for the welding and processing of PACK modules in the lithium battery

industry. Yaskawa servo motors and YYC precision racks are used. The equipment wiring design is reasonable and the motion control precision is extremely high.

industry. Yaskawa servo motors and YYC precision racks are used. The equipment wiring design is reasonable and the motion control precision is extremely high.

Equipment operation is simple and easy to learn:

Using the second-developed lithium battery PACK module dedicated welding software, welding programming is easy and convenient,

improving work efficiency and saving labor costs.

improving work efficiency and saving labor costs.

Specification

|

Model

|

MAS-SpotWelder-2000W

|

MAS-SpotWelder-3000W

|

MAS-SpotWelder-6000W

|

|

Laser Power

|

2000W

|

3000W

|

6000W

|

|

Processing format

|

1.6m workbench (can be customized)

|

1.6m workbench (can be customized)

|

1.6m workbench (can be customized)

|

|

XYZ axis

|

1000*800*500mm (can be customized)

|

1000*800*500mm (can be customized)

|

1000*800*500mm (can be customized)

|

|

Operating mode

|

Continuous/Pulse

|

Continuous/Pulse

|

Continuous/Pulse

|

|

Center wavelength

|

1080±5nm

|

1080±5nm

|

1080±5nm

|

|

Beam quality

|

1.3M2

|

1.3M2

|

1.3M2

|

|

Maximum modulation frequency

|

5KHz

|

5KHz

|

5KHz

|

|

Waveform settings

|

Arbitrary inflection point waveform setting, 1-20 inflection point

|

Arbitrary inflection point waveform setting, 1-20 inflection point

|

Arbitrary inflection point waveform setting, 1-20 inflection point

|

|

Cooling method

|

Dual temperature dual control external chiller

|

Dual temperature dual control external chiller

|

Dual temperature dual control external chiller

|

|

Operating Voltage

|

380V/50-60HZ

|

380V/50-60HZ

|

380V/50-60HZ

|

Application

Battery aluminum electrode welding

Square battery bus bar welding

16850 battery bus bar welding

Battery aluminum electrode welding

Hot Searches