- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C3H7O*

-

EINECS No.:

-

618-389-6

-

Place of Origin:

-

Hebei, China

-

Type:

-

Chemical auxiliaries

-

Brand Name:

-

Qingquan

-

Model Number:

-

K200,K150,K100

-

Appearance:

-

White Power

-

Keywords:

-

High Purity HPMC Powder

-

Package:

-

25kg/bag

-

Certification:

-

ISO9001

-

Sample:

-

Free(1-2 Kg)

-

MOQ:

-

1kg

-

Advantage:

-

Fast Delivery

-

Viscosity:

-

400-200000 Mpa.s

-

Grade:

-

Industrail Grade

-

Chemical name:

-

HPMC

Quick Details

-

CAS No.:

-

9004-65-3

-

Purity:

-

99.99%

-

Other Names:

-

HPMC,HEMC,MHEC

-

MF:

-

C3H7O*

-

EINECS No.:

-

618-389-6

-

Place of Origin:

-

Hebei, China

-

Type:

-

Chemical auxiliaries

-

Brand Name:

-

Qingquan

-

Model Number:

-

K200,K150,K100

-

Appearance:

-

White Power

-

Keywords:

-

High Purity HPMC Powder

-

Package:

-

25kg/bag

-

Certification:

-

ISO9001

-

Sample:

-

Free(1-2 Kg)

-

MOQ:

-

1kg

-

Advantage:

-

Fast Delivery

-

Viscosity:

-

400-200000 Mpa.s

-

Grade:

-

Industrail Grade

-

Chemical name:

-

HPMC

|

Items

|

Technical data

|

|

Appearance

|

White or off-white powder

|

|

Methoxy

|

19%~24%

|

|

Hydroxypropoxy

|

4%~12%

|

|

Viscosity range (2%,Brookfield)

|

400-65000 mPa.S

|

|

Viscosity range (1%, NDJ)

|

400-200000 mPa.S

|

|

Moisture

|

≤5 %

|

|

PH Value

|

7-9

|

|

Gel temperature

|

75 %

|

|

Packing Density

|

250 – 360g/l

|

Product characteristics

Product characteristics

HEMC can be used as the adhesive for plastering mortar, gypsum materials, putty powder and other building materials to improve the coating performance and prolong the service time. It can also be used to paste ceramic tiles, marble, plastic decoration, paste reinforcing agent, and reduce the amount of corresponding materials.

1. Surface activity: HEMC aqueous solution has surface activity function and can be used as colloid protector, emulsifier and dispersant.

2. Water retention: HEMC is a highly effective water retention agent, which is widely used in ceramics, building materials and many other aspects.

3. Hot gel: When heated to a certain temperature, HEMC aqueous solution becomes opaque, gel forms precipitation, but when cooled continuously, it returns to the original solution state.

The role of the product.

1.HEMC is mainly used as water retaining agent and thickener in cement-based materials. Its water retaining function can prevent the base material from absorbing too much and too quickly and prevent the evaporation of water, so as to ensure that there is enough water when the cement is hydrated.

2.HEMC can increase the workability of mortar. Make it easier for constructors to operate.

Product characteristics of Qingquan cellulose ether

Its appearance is usually white or almost white powder. It is soluble in water and some solvents, and the aqueous solution has surface activity. Very good transparency. The performance is also relatively stable. HPMC can produce products of different specifications, and the gel temperature is also different. Solubility changes with viscosity. The lower the viscosity, the greater the solubility. HPMC with different specifications has different performance.

HPMC has thickening ability, salt resistance, low ash content, PH stability, water retention, dimensional stability, excellent film forming performance, and extensive enzyme resistance, dispersion and cohesion.

Its role in materials.

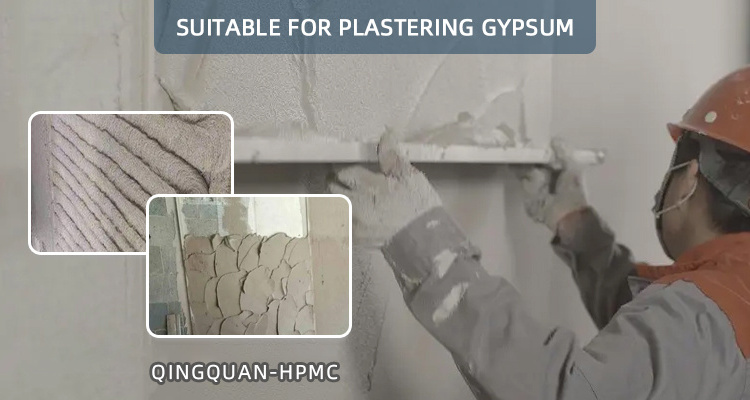

1.Among gypsum series products , cellulose ethermainly plays the role of water retention andlubrication.

2.At the same time . it has a certain retarding effectwhich solves the problem of hollowing and crackingeasily occurring in the construction process

Product characteristics

MHEC has the advantages of thickening, water retention and increased workability.

The thickening mechanism of cellulose ether is that the hydrophobic main chain is associated with surrounding water molecules through hydrogen bond, which increases the fluid volume of the polymer itself, reduces the space for free movement of particles, and thus improves the viscosity of the system. The viscosity can also be improved by winding the molecular chain, which is shown as high viscosity under static and low shear, and low viscosity under high shear. This is because the cellulose molecular chain is in a disordered state at static or low shear speed, which makes the system highly viscous.

The role of the product.

MHEC mainly plays the role of water retention, bonding and lubrication in the putty, avoiding cracks and dehydration caused by rapid water loss, enhancing the adhesion of the putty, reducing sagging during construction, and making the construction more smooth.

Product characteristics of Qingquan cellulose ether

Its appearance is usually white or almost white powder. It is soluble in water and some solvents, and the aqueous solution has surface activity. Very good transparency. The performance is also relatively stable. HPMC can produce products of different specifications, and the gel temperature is also different. Solubility changes with viscosity. The lower the viscosity, the greater the solubility. HPMC with different specifications has different performance.

HPMC has thickening ability, salt resistance, low ash content, PH stability, water retention, dimensional stability, excellent film forming performance, and extensive enzyme resistance, dispersion and cohesion.

Role in construction

1.The water retention property can fully hydratethe mortar and significantly improve thebonding strength.

2

.At the same time , the tensile elongation andshear strength can be appropriately improved ,greatly improving the construction effect andworking efficiency .

3

.At the same time , it also improves the bondingperformance , has the anti sag ability , andimproves the anti shrinkage and anti crackingperformance .

Product characteristics of Qingquan cellulose ether

Its appearance is usually white or almost white powder. It is soluble in water and some solvents, and the aqueous solution has surface activity. Very good transparency. The performance is also relatively stable. HPMC can produce products of different specifications, and the gel temperature is also different. Solubility changes with viscosity. The lower the viscosity, the greater the solubility. HPMC with different specifications has different performance.

HPMC has thickening ability, salt resistance, low ash content, PH stability, water retention, dimensional stability, excellent film forming performance, and extensive enzyme resistance, dispersion and cohesion.

Its function

The cellulose added in the putty powder is mainly due to the water retention property of hpmc, so that the slurry will not crack due to drying too fast after application, and the strength after hardening will be enhanced.

When putty powder is used for operation, hydroxypropyl methyl cellulose is usually added. The role of hydroxypropyl methyl cellulose in construction is water retention, construction and thickening.

1. Water retention: make the putty powder dry slowly and assist the lime calcium to react under the action of water.

2. Construction: cellulose has lubricating effect and can make putty powder have good workability.

3. Thickening: cellulose can thicken and play a role in suspension, keeping the solution uniform up and down, and resisting sagging.

Product characteristics of Qingquan cellulose ether

Its appearance is usually white or almost white powder. It is soluble in water and some solvents, and the aqueous solution has surface activity. Very good transparency. The performance is also relatively stable. HPMC can produce products of different specifications, and the gel temperature is also different. Solubility changes with viscosity. The lower the viscosity, the greater the solubility. HPMC with different specifications has different performance.

HPMC has thickening ability, salt resistance, low ash content, PH stability, water retention, dimensional stability, excellent film forming performance, and extensive enzyme resistance, dispersion and cohesion.

Cellulose ether is the main additive of ready-mixed mortar. Although the addition of cellulose ether is very low, it can significantly adjust the performance of mortar. It can adjust the consistency, workability, adhesion and water retention of mortar. It plays a very important role in the field of ready-mixed mortar.

1.Low viscosity hydroxypropyl methyl cellulose has an important effect on the water retention consistency and workability of self-leveling mortar. On the premise of normal mortar composition, the fluidity of mortar can be adjusted by changing the content of cellulose ether.

2.In order to fully hydrate the gel material, an appropriate amount of HPMC can maintain the moisture in the mortar for a long time. The viscosity of HPMC also has a great influence on the water retention of mortar. The higher the viscosity, the better the water retention. Hydroxypropyl methyl cellulose with a general viscosity of 400 mpa. It is mainly used for self-leveling mortar, which can improve the leveling performance and compactness of mortar

3.The setting time of mortar increases with the increase of cellulose ether content. The retarding effect of HPMC on cement paste mainly depends on the degree of alkyl substitution, and has little relationship with its molecular weight. The higher the content of cellulose ether, the more obvious the retarding effect of composite membrane on early hydration of cement

Hot Searches