- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

58U 59U

-

Standard or Nonstandard:

-

Standard

-

Type 2:

-

58U

-

Type 1:

-

59U

-

Application:

-

Industry

-

Sealing face:

-

Carbon,SIC,SSIC,TC,SS,Ceramic

-

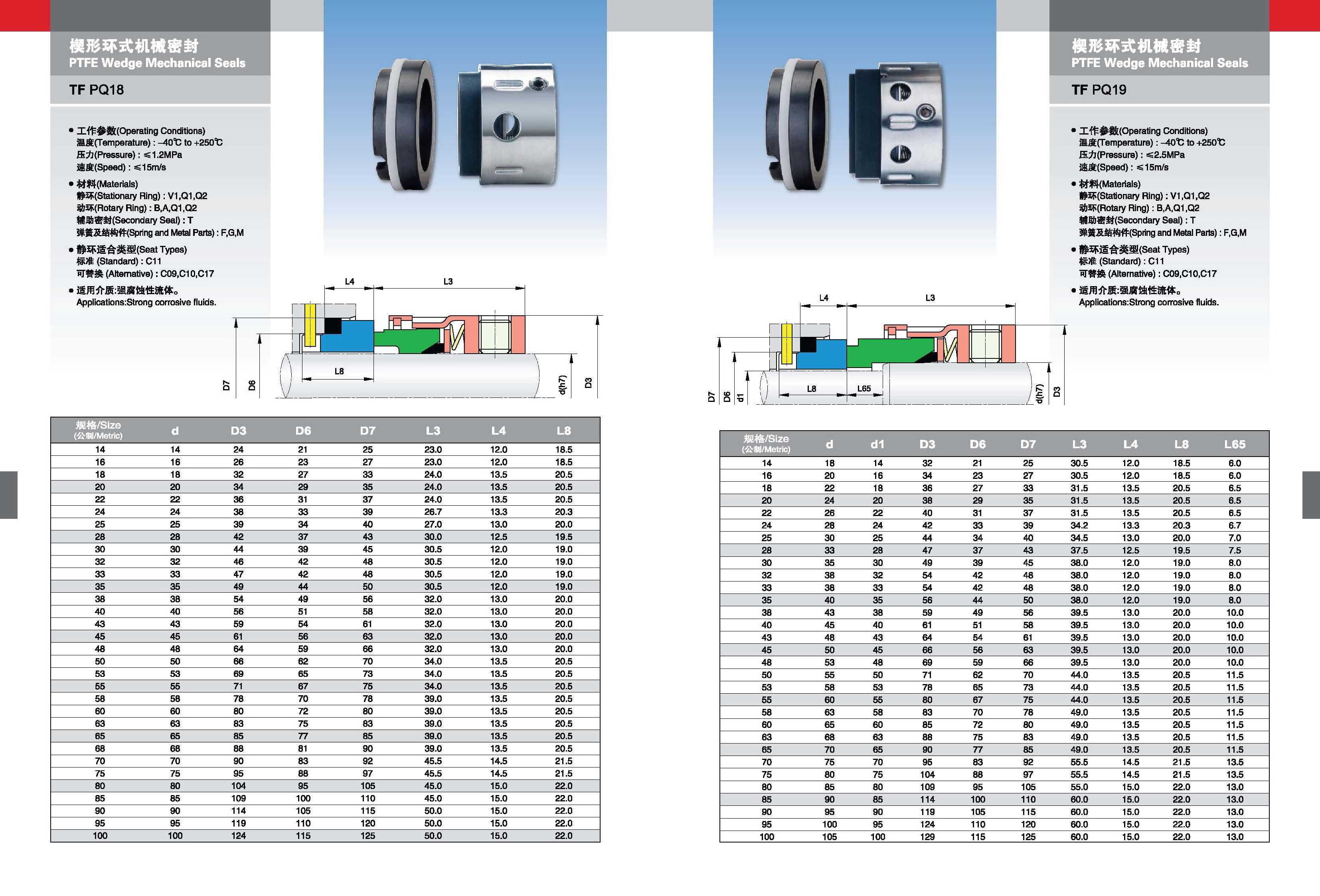

PQ18/PQ19:

-

Equivalent to 58U/59U/58B/58B)

Quick Details

-

Size:

-

Johncrane 58U/59U mechanical seal

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FLEX chinabase,OEM

-

Model Number:

-

58U 59U

-

Standard or Nonstandard:

-

Standard

-

Type 2:

-

58U

-

Type 1:

-

59U

-

Application:

-

Industry

-

Sealing face:

-

Carbon,SIC,SSIC,TC,SS,Ceramic

-

PQ18/PQ19:

-

Equivalent to 58U/59U/58B/58B)

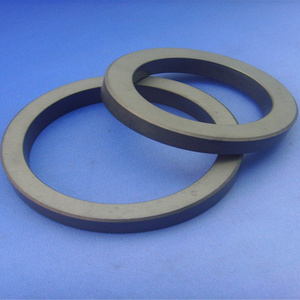

Combination of materials :

Sealing face:Carbon,SIC,SSIC,TC,SS,Ceramic

Secondary sealing:NBR,VITON, EPDM,PTFE,FFKM,GRAFOIL

Metal component:304SS,316SS,2205SS

Operating limits

Pressure: ≤1.7 Mpa

Temperature: -20°C-200°C

Linear speed: ≤25 m/s

Specification: 14mm-100 mm

Description

General Purpose DIN, Multi-spring, O-ring Pusher Seal

Elastomer O-ring SealA DIN seal for general low- to medium-pressure duties in the processing, refinery and petrochemical industries. Alternative seat designs and material options are available to suit product and operating conditions of applications. Typical applications include oils, solvents, water and refrigerants, in addition to a multitude of chemical solutions.

This series mechanical seal is designed with multi spring structure, and is compact in structure. It has a small axial size and reliable tightness. It is widely used in oil, water, organic solvent, and other weak corrosive medium.

The Type 58U/59U/58B/59B is multi-spring designed mechanical seal according to DIN 24960 and EN12756,

58U is Unbalance style mechanical seal with Rubber Oring Secondary seal

59U is Unbalance style mechanical seal with PTFE Secondary seal

58B is Balance style mechanical seal with Rubber Oring Secondary seal

59B is Balance style mechanical seal with PTFE Secondary seal

General chemical applications, oil refining, petrochemical,

and pharmaceutical industries.

Suitable for use with corrosive fluids and for cryogenic

and high-temperature applications.

By choosing suitable component materials, the seals can

be adapted to operate with a wide range of liquids and

operating conditions