- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

insight, INSIGHT

-

Model Number:

-

spiral pointed tap

-

Product name:

-

Spiral Fluted Tap

-

Material:

-

High Speed Steel

-

Coating:

-

TICN,DLC,TIN

Quick Details

-

Warranty:

-

1 years

-

Type:

-

Tap & Die Set

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

insight, INSIGHT

-

Model Number:

-

spiral pointed tap

-

Product name:

-

Spiral Fluted Tap

-

Material:

-

High Speed Steel

-

Coating:

-

TICN,DLC,TIN

|

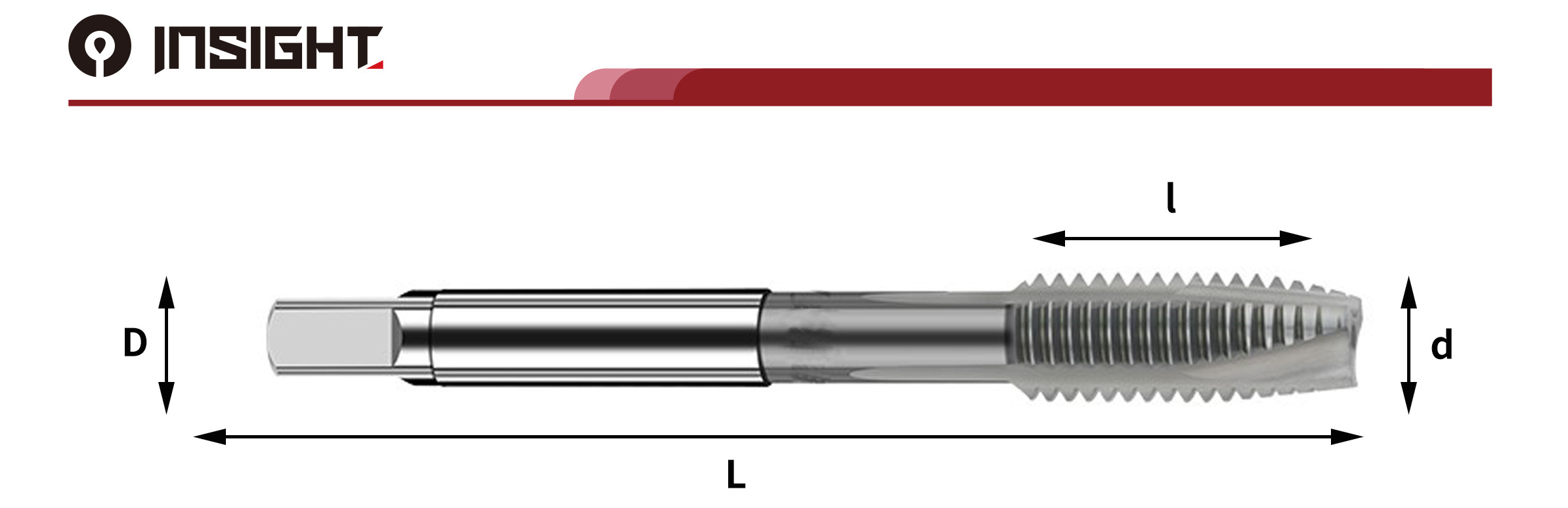

Model

|

d

|

l

|

D

|

L

|

|

M3

|

3

|

13

|

3

|

51

|

|

M4

|

4

|

18

|

3

|

57

|

|

M5

|

5

|

20

|

4

|

63

|

|

M6

|

6

|

27

|

5

|

69

|

|

M8

|

8

|

22

|

5

|

72

|

|

M10

|

10

|

24

|

6

|

77

|

|

M12

|

12

|

29

|

7

|

88

|

|

M14

|

14

|

31

|

9

|

95

|

|

M16

|

16

|

38

|

11

|

101

|

|

M18

|

18

|

37

|

14

|

116

|

|

M20

|

20

|

39

|

11

|

112

|

|

M22

|

22

|

42

|

16

|

118

|

|

M24

|

24

|

47

|

18

|

130

|

Product Introduction

1. The use of high-quality high-speed steel materials with certain hardness and high toughness can withstand high torque pressure.

2. This product mainly allows the material chips to be discharged downwards. The unique groove design makes the center shape of the blade larger and can withstand larger cutting forces to achieve the best chip removal effect.

3. corresponding nano coatings for different processing materials to improve efficiency and reduce error rates and the possibility of breakage during processing.

4.

The design of the internal cooling center water outlet achieves a significant cooling effect, increasing the resistance performance of the tap tool and allowing

it

to maintain

the best condition for processing high hardness materials for a long time.

Hot Searches