- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

10000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V/380V

-

Rice flakes processing machine:

-

For frying snack production

-

Frying snack machine:

-

Frying snack machinery

-

Frying snack proessing line:

-

120kg/hr and more

-

Minimu capacity:

-

120kg/hr and 220kg/hr

-

Reasonable price:

-

Good service

-

High quality:

-

Advanced technology

-

Main machine:

-

Single screw etruder, dryer and fryer

-

Application:

-

Rice flakes machinery

-

Certification:

-

CE, SGS

-

Power:

-

95kw

Quick Details

-

Machinery Capacity:

-

100

-

Brand Name:

-

SBN

-

Dimension(L*W*H):

-

2300*1650*2100mm

-

Weight:

-

10000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V/380V

-

Rice flakes processing machine:

-

For frying snack production

-

Frying snack machine:

-

Frying snack machinery

-

Frying snack proessing line:

-

120kg/hr and more

-

Minimu capacity:

-

120kg/hr and 220kg/hr

-

Reasonable price:

-

Good service

-

High quality:

-

Advanced technology

-

Main machine:

-

Single screw etruder, dryer and fryer

-

Application:

-

Rice flakes machinery

-

Certification:

-

CE, SGS

-

Power:

-

95kw

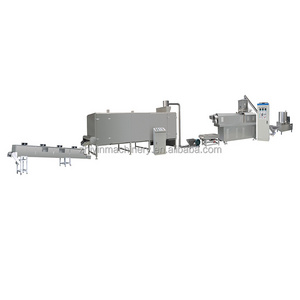

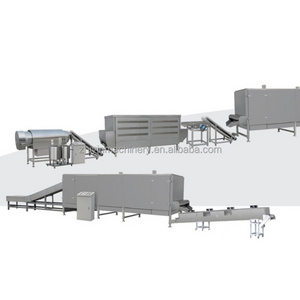

fried Rice flakes processing line, plant, machine

Rice flakes processing machines adopt the rice flour as the raw material then form a kind of leisure food after extruding, cutting(shaping), drying, frying and flavoring. Saibainuo Company has improved the production line performance by means of the marketing research and our own technology and make the operator operate the equipment easily and make the craft more perfect. This is indispensable production food equipment for everyone taking on the food profession. We hope that Saibainuo can provide more opportunity and wealth for you.

Flow chart of fried Rice flakes processing line, plant, machine,extruder :

Raw material→ Mixing→ Conveying → Extruding→ Cutting → Hoisting → Drying→ Hoisting → Frying →Flavoring → Cooling

Sample pictures for reference:

Details for Rice Flakes Processing Machinery

Twin screw extruder adopts the extrusion technology.

After the cereals is extruded, the products will become bigger, puffy texture, crisp taste, starch form, increasing the water dissolve,

easy to absorb by human, thus, it is popular in the world.

Twin screw extruder has the following part:

feeding system, extrusion system, cutting system, heating system, lubricating system, driving system, control system

Saibainuo Company Service for

Rice Flakes Processing Machinery:

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

To packing corn puffs snacks corn flakes machine:

Firstly clean the equipment and using the Standard packaging film wrap them carefully.

Second, Precision measurement equipment size, make independent wooden packaging of each machine.

Our purpose to keep mach in e safe during deli very .

Also can sat i sfied your needs, about inspection & quarantine , CIQ, fumigation , etc.