PS:

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the

isobaric

pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink , cold brew coffee, herbal tea and so on.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

3PH 380V 50HZ

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

2580*1550*2000

-

Weight:

-

600 KG

-

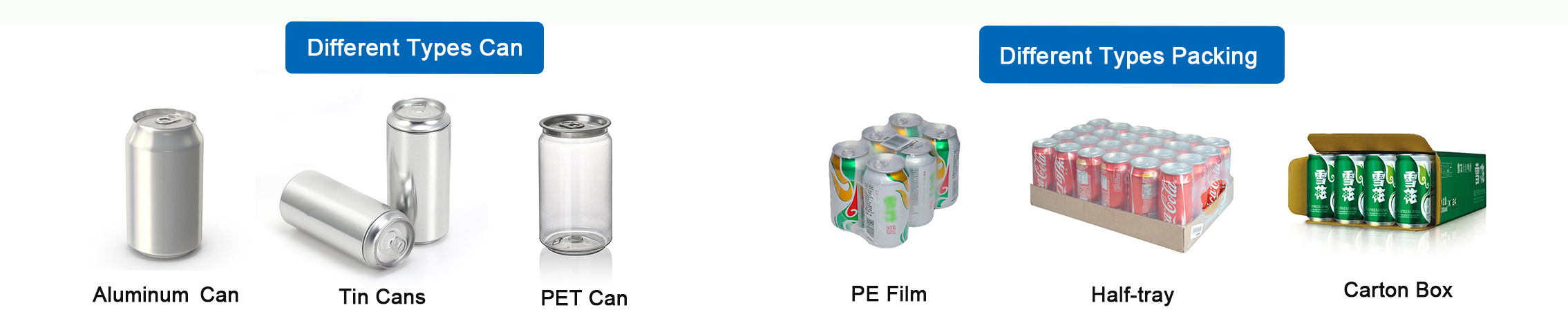

Suitable bottle::

-

Pop can / Aluminum can / Tin can

-

Filling material:

-

Soft drinks / Beer

-

Filling speed:

-

2000CPH

-

Filling volume:

-

200-1000ml

-

Function:

-

Filling & Seaming

-

Material:

-

SUS304 / 316

-

Suitable for::

-

Carbonated beverage

Quick Details

-

Machinery Capacity:

-

2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Beer, Other, Carbonated Drink

-

Filling Accuracy:

-

99%

-

Voltage:

-

3PH 380V 50HZ

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

2580*1550*2000

-

Weight:

-

600 KG

-

Suitable bottle::

-

Pop can / Aluminum can / Tin can

-

Filling material:

-

Soft drinks / Beer

-

Filling speed:

-

2000CPH

-

Filling volume:

-

200-1000ml

-

Function:

-

Filling & Seaming

-

Material:

-

SUS304 / 316

-

Suitable for::

-

Carbonated beverage

Products Description

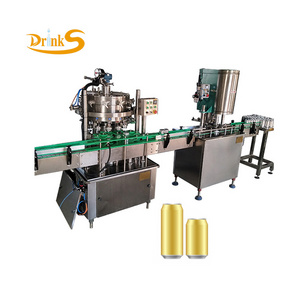

Linear Type 2000CPH CSD Carbonated Drink Can Filling Machine For Small Business

We provide the complete Can filling and package solution ,from can depalletizer ,can rinsing machine ,can filling & sealing monoblock machine ,leakage check,liquid nitrogen dosing machine ,pasteurizer tunnel ,blow dryer ,carton package ,film package system ,which is widely used for the beverage ,beer ,Juice industry and so on.

Details Images

Can Filling Sealing Machine

Cans go through conveyor to filler, the diameter plate will turn the cans to can stands, with the motor driven energy, the can stands go up and forward along the principal axis; When the cans go through gas valve opening position, the trigger on liquid tank will open the valve, at the mean time the bottle mouth will be pressed closely to filling valve head, and the CO2 gas will be put into the bottles, when the pressure inside bottle is same as in liquid tank, the filling valve will be started to fill. and filling finish when filling head apart from can mouth, and then can was sent out the machines. The speed control is by motor speed. Whole machine is made by SUS304.The filling head is spring type, no dead angel, no dripping.

|

Capacity:

|

2000CPH

|

|

|

|

|||

|

Construction:

|

SUS304 frames+ liquid tank + filling heads + can transmission system+ conveyor rail

|

|

|

|

|||

|

Filling Type:

|

Isobaric / Normal pressure

|

|

|

|

|||

|

Power:

|

0.75KW

|

|

|

|

|||

|

Dimension:

|

1300*1070*1900mm

|

|

|

|

|||

|

Weight:

|

800KG

|

|

|

|

|||

Single Head Can Sealing Machine

Cans will go to the can sealing machine through conveyor. The 8 station dia plate will turn the cans under lid loading head , the lid will be loaded on can mouth automatically with the can body triggering. With the motor driven energy, the can which already be loaded with lid will go forward to sealing position. With the lifting cam, the sealing head can go up and down when cans come and go. The sealing head will go down to press on the can when the cans come; The sealing head are composed with 4 groups of sealing wheels around one circle, the 4 groups of wheels will turn rapidly together with sealing head in the same direction to process sealing job. The whole system will finish edge rolling job.

The sealing wheels are in 2 step sealing model to make sure the the can edge and lid edge close tightly. Then the sealed can will be suitable for all kinds of liquid, no leakage.

|

Capacity:

|

MAX 2400CPH

|

|

|

|

|||

|

Power:

|

0.75KW

|

|

|

|

|||

|

Dimension:

|

1000*900*1700mm

|

|

|

|

|||

|

Weight:

|

500KG

|

|

|

|

|||

Can Rinser

Function : washing can inside and outside dust .

The whole set can washing machine including: 1 can spearation motor + 1meter conveyor with motor + 2 reverse units + 1 can washing machine

Choose More Products

Why Choose Us

About Ruihengyuan:

Set up in 2007, Ruihengyuan leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

Advantage:

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)20+ mechanical, electrical and food science engineers

(4)Serve customers over 50 countries and regions worldwide

Certifications

Our products with customer

FAQ

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packaging machines. We offer turnkey solutions with more than 15 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If

needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q

7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Hot Searches