- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HNJS

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1000

-

Material:

-

Q235B

-

Application:

-

Industry

-

Advantage:

-

Easy Moving

-

Color:

-

White or Customer's Requirement

-

Type:

-

Moveable

-

Working medium:

-

diesel fuel oil

-

Surface treatment:

-

Mirror Finish

-

Working Years Design:

-

20 Years

-

Product name:

-

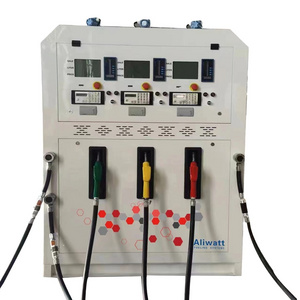

Mobile diesel fuel tank with pump

-

Name:

-

Mobile/portable petrol fuel station with dispenser/pump

Quick Details

-

Capacity:

-

500-1000gallon

-

Max Working Pressure(MPa):

-

1.7 MPa

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNJS

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1000

-

Material:

-

Q235B

-

Application:

-

Industry

-

Advantage:

-

Easy Moving

-

Color:

-

White or Customer's Requirement

-

Type:

-

Moveable

-

Working medium:

-

diesel fuel oil

-

Surface treatment:

-

Mirror Finish

-

Working Years Design:

-

20 Years

-

Product name:

-

Mobile diesel fuel tank with pump

-

Name:

-

Mobile/portable petrol fuel station with dispenser/pump

Mobile/portable petrol fuel station with dispenser/pump

Product description

Mobile fuel station – HNJS Engineering supply and install quality manufactured fuel storage tanks for petroleum with complete fuel dispensing systems for commercial and retail fuel stations. Designed for storage and handling of flammable and combustible liquids such as petrol, diesel, kerosene. These tanks can also be used for storage of coconut oil, palm oil or any other types of oil. Depending on your needs you can either rest the tank on steel pedestal or on cement pedestal.

Application

Different filling systems,hospital helicopterfuel filling system,airplane fuel filling system,vessel fuel filling system,construction of outdoor tanks storage,transportation device of different liquid,chemical device,petroleum device,filling station,selling and repairing of measurement device,selling and repairing of vehicle washing machine,oil piping and storage device of other dangerous goods.

Production process

1. Volume and size confirmation, drawing production, risk assessment report

2. welding process / pressure test evaluation

3. Material acceptance; material acceptance of pressure components

4.barrel manufacturing: size cutting → roll forming → welding → tube section calibration after inspection → RT test.

5. check the hole connector / flange / flange cover pair → welding → inspection 6. the joint between the shell ring seam welding → RT inspection / MT inspection

7. Appearance inspection / hydraulic pressure test / air tightness test

8.rust blasting → paving film

Our advantages

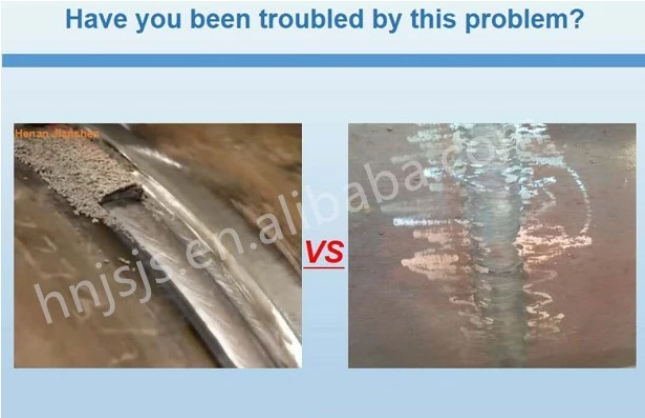

1.Our welding method

We use mechanical automatic welding, it is a method in which an electric arc is burned under the flux layer for welding. stable welding quality, high welding productivity, there is no arc and smoke dust and so on, so that our product are neat, smooth and beautiful, also extend the service life.

2.Professional testing

All the tank must do nondestructive examination, air tight test, water pressure test and X-Ray test and any other inspections to ensure our product quality.

Our Company

Our company's main products are vacuum adiabatic cryogenic liquid storage tank, mobile fuel station, cryogenic pump and so on. At the same time,we can design for customers, so that the equipment manufacturing, installation, commissioning, training operators to form one-stop service and non-standard pressure vessels, widely used in petroleum, chemical, pharmaceutical, metallurgy, air separation, cooking and other industries.

Certificate

Our Compaty certificate includes ISO9001, China special equipment manufacturing license (Class I pressure vessel, Class II low, medium pressure vessel, High pressure vessel, Class III low medium pressure vessel), radiation Safety license, Utility Model Patent Certificate, etc.

Packing&Shipping

Nude or plastic film package or according to customer's request packing of mobile fuel station.

Contact us

Any problem welcome to contact me freely!