- Product Details

- {{item.text}}

Quick Details

-

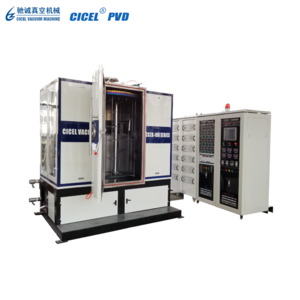

Brand Name:

-

BEQ

-

Voltage:

-

220V 50/60HZ

-

Power:

-

3KW

-

Dimension(L*W*H):

-

1360X470X720+680X780

-

Weight (KG):

-

350

-

Product name:

-

Vacuum Film Deposition Machine

-

Name:

-

Magnetron Plasma Sputtering Coater

-

Technology:

-

Plasma Technology

-

Control System:

-

PLC+Touch Screen Automatic

-

Control mode:

-

Full-automatic

-

Raw Material:

-

Aluminum Sheet

-

Function:

-

Vacuum Coating Functional Film

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

electric heating type, Other

-

Warranty of core components:

-

heating tube furnace

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

BEQ

-

Voltage:

-

220V 50/60HZ

-

Power:

-

3KW

-

Dimension(L*W*H):

-

1360X470X720+680X780

-

Weight (KG):

-

350

-

Product name:

-

Vacuum Film Deposition Machine

-

Name:

-

Magnetron Plasma Sputtering Coater

-

Technology:

-

Plasma Technology

-

Control System:

-

PLC+Touch Screen Automatic

-

Control mode:

-

Full-automatic

-

Raw Material:

-

Aluminum Sheet

-

Function:

-

Vacuum Coating Functional Film

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE

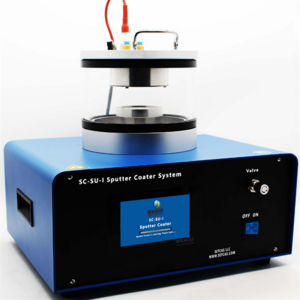

1.The BTF-1200C-CVD series furnace workstation consists of BTF-1200C series single zone (optional)

tube furnace, a precision mass flow gas control station, a low vacuum station and other assembling parts. We adopted imported vacuum pump and valve with reliable quality.

The max. working temperature of this workstation is 1200°C. The ultimate vacuum rate goes to 10-1pa (with our sealing assembly provided). The mass flow gas control station mixes several kinds of gas together and input the mixed gas into a fused quartz tube inside the furnace.

2. The technology of control circuit is vague PID automatic control with high precision temperature and operate easily.

3.The CVD growing-system can be used in CVD art,like carborundum substrate coating,conductivity test of ceramic film,controlled growth of Zno nanometer structure and MLCC atmosphere sintering experiment etc.

Heat furnace :

rated power :3kw

rated voltage :208-240v ,50/60hz

max tem:1200°C

continue working tem:≤1000°C

suggest heat rate :≤15°C/min

Tube size :OD25 /50/60/80X 1000mm.

Heat zone length :200+200mm

constant heat zone length :100+100mm

Tem control :PID fuzzy selftuning ,intelligent 30segment programmable ,with over heat and thermocouple broken alarm function .

gas system :2 chanel gas input system

floating flowmeter gauge : 10-100ml/min ,16-160ml /min ,25-250ml

machinical pressure gauge range :-0.1-0.15Mpa (0.01mpa /grid )

needle valve :316 stainless steel

gas mixed can :OD80x140mm

stop valve :316 stainless needle valve

vacuum system : Vau-02

vacuum speed :3x10-3 mbar

test range :5X10-3 --- 5X10-1pa