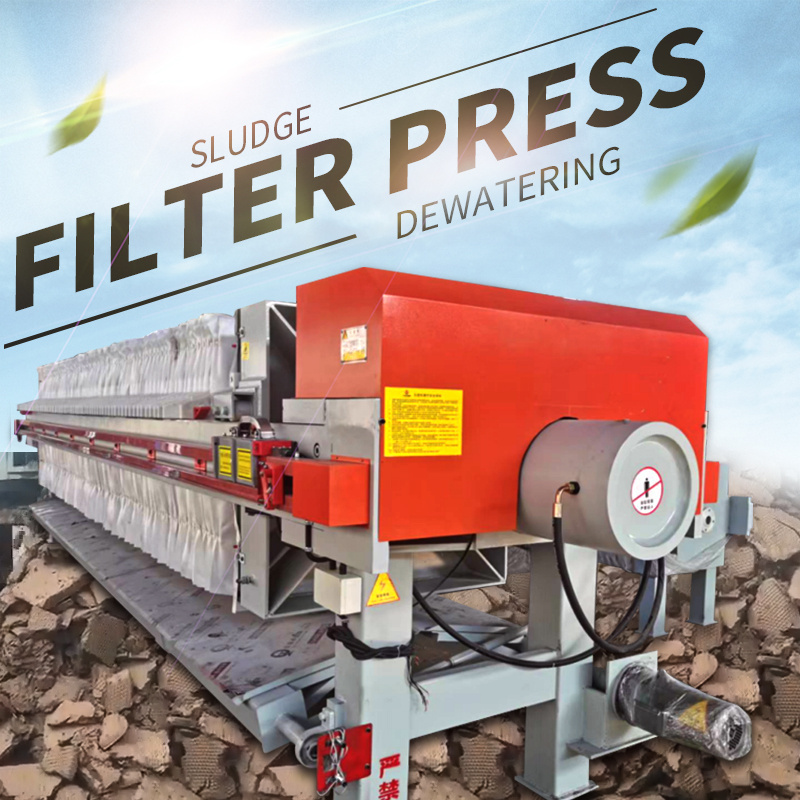

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

50

-

Size:

-

1200x1000x500

-

Power:

-

55kw

-

Weight (KG):

-

500 kg

-

Name:

-

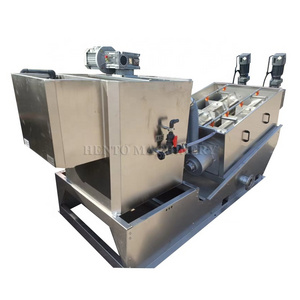

sludge dehydrator belt filter press

-

belt width:

-

1000-3000mm

-

belt filter press treatment capacity:

-

4-50m3/h, or more

-

Manufacturing lead time:

-

35-40 working days

-

Who we are:

-

9 years belt filter press supplier

-

belt filter press water consumption:

-

6-18 m3/h or less

-

Washing Water Pressure:

-

More than 0.5 Mpa

-

belt filter press application:

-

belt filter press for sludge dewatering

-

Mud Cake Moisture Content:

-

75-80%

-

belt filter press package:

-

Wooden box

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JinWanTong

-

Material:

-

carbon steel

-

Weight:

-

50

-

Size:

-

1200x1000x500

-

Power:

-

55kw

-

Weight (KG):

-

500 kg

-

Name:

-

sludge dehydrator belt filter press

-

belt width:

-

1000-3000mm

-

belt filter press treatment capacity:

-

4-50m3/h, or more

-

Manufacturing lead time:

-

35-40 working days

-

Who we are:

-

9 years belt filter press supplier

-

belt filter press water consumption:

-

6-18 m3/h or less

-

Washing Water Pressure:

-

More than 0.5 Mpa

-

belt filter press application:

-

belt filter press for sludge dewatering

-

Mud Cake Moisture Content:

-

75-80%

-

belt filter press package:

-

Wooden box

Products Description

What is a belt filter press?

Belt filter press is also called belt p https://jwthb.en.alibaba.com/product/60538460241-807377962/plastic_film_food_dewatering_machine_cow_dung_Dewatering_Sludge_Machine_Screw_Press_Sludge_Dewatering_Machine_Super.html ress or belt mud dehydrator, is widely used in both domestic and abroad market for its

excellent performance and low investment & costs.

WDY series belt filter press embodies all the recognized principles of good belt filter press design. It is simple, reliable and

easy to operate. The design has sufficient flexibility to accommodate nearly all types of sludges which are likely to be generated

in a treatment facility.

All components are rugged, heavy-duty industrial quality suited for continuous 24 hr./day, 7 day/wk. service. As a experienced

belt filter press supplier, we have been over 9 years in manufacturing and designing of belt filter press since 2006.

Belt filter press is also called belt p https://jwthb.en.alibaba.com/product/60538460241-807377962/plastic_film_food_dewatering_machine_cow_dung_Dewatering_Sludge_Machine_Screw_Press_Sludge_Dewatering_Machine_Super.html ress or belt mud dehydrator, is widely used in both domestic and abroad market for its

excellent performance and low investment & costs.

WDY series belt filter press embodies all the recognized principles of good belt filter press design. It is simple, reliable and

easy to operate. The design has sufficient flexibility to accommodate nearly all types of sludges which are likely to be generated

in a treatment facility.

All components are rugged, heavy-duty industrial quality suited for continuous 24 hr./day, 7 day/wk. service. As a experienced

belt filter press supplier, we have been over 9 years in manufacturing and designing of belt filter press since 2006.

Working principle of belt filter press WDY Series:

Free water and sludge is fully separated at gravity dewatering zone and then enter into 3-stage pressure dewatering

zone---pre-pressure rollers, low pressure rollers and high pressure rollers.

Sludge is gradually dewatered under pressure and is discharged as sludge cake. WDY series belt filter press is your ideal choice

for sludge dewatering.

https://jwthb.en.alibaba.com/product/60538460241-807377962/plastic_film_food_dewatering_machine_cow_dung_Dewatering_Sludge_Machine_Screw_Press_Sludge_Dewatering_Machine_Super.html

Free water and sludge is fully separated at gravity dewatering zone and then enter into 3-stage pressure dewatering

zone---pre-pressure rollers, low pressure rollers and high pressure rollers.

Sludge is gradually dewatered under pressure and is discharged as sludge cake. WDY series belt filter press is your ideal choice

for sludge dewatering.

https://jwthb.en.alibaba.com/product/60538460241-807377962/plastic_film_food_dewatering_machine_cow_dung_Dewatering_Sludge_Machine_Screw_Press_Sludge_Dewatering_Machine_Super.html

Uses of belt filter press:

WDY belt filter press is mainly used for sludge dewatering in municipal sewage treatment plants, pharmaceutical industry,

electroplating industry, paper industry, leather industry, printing and dyeing industry, metallurgy industry, chemical industry,

slaughter industry, food industry, wine manufacturing factory and environmental engineering plants.

Also WDY belt filter press can be used for solid-liquid separation and resource recovery in industrial production, like:

* In steel plants: Dewater and recycle iron powder.

* In wineries: solid-liquid separation from vinasse.

* In stone factories: Dewater and recycle stone powder.

WDY belt filter press is simple and easy to maintain, sludge cake moisture content rate is very low.

WDY belt filter press is mainly used for sludge dewatering in municipal sewage treatment plants, pharmaceutical industry,

electroplating industry, paper industry, leather industry, printing and dyeing industry, metallurgy industry, chemical industry,

slaughter industry, food industry, wine manufacturing factory and environmental engineering plants.

Also WDY belt filter press can be used for solid-liquid separation and resource recovery in industrial production, like:

* In steel plants: Dewater and recycle iron powder.

* In wineries: solid-liquid separation from vinasse.

* In stone factories: Dewater and recycle stone powder.

WDY belt filter press is simple and easy to maintain, sludge cake moisture content rate is very low.

Product features of belt filter press:

* Fully automatic, save labor.

* Small vibration and low noise.

* Excellent performance with very small footprint.

* Adaptable for nearly all types of sludges, high efficiency with large treatment capacity.

* Dewatering happens in several zone one by one with high dewatering efficiency, sludge cake moisture content is much low.

* Belt filter press can run continuously around the clock, and can automatically backwash, easy to maintain.

* Low energy consumption and low running costs.

* Filter belt deviation can be automatically calibrated, more safe.

* Strong technical team and strict final inspections ensure excellent quality and long service life of our belt filter press.

* Cheap factory price from 8 year experience belt filter press supplier for you.

* Fully automatic, save labor.

* Small vibration and low noise.

* Excellent performance with very small footprint.

* Adaptable for nearly all types of sludges, high efficiency with large treatment capacity.

* Dewatering happens in several zone one by one with high dewatering efficiency, sludge cake moisture content is much low.

* Belt filter press can run continuously around the clock, and can automatically backwash, easy to maintain.

* Low energy consumption and low running costs.

* Filter belt deviation can be automatically calibrated, more safe.

* Strong technical team and strict final inspections ensure excellent quality and long service life of our belt filter press.

* Cheap factory price from 8 year experience belt filter press supplier for you.

Details Images

|

Model

|

WDY10

|

WDY15

|

WDY20

|

WDY25

|

WDY30

|

|

Belt Width(mm)

|

1000

|

1500

|

2000

|

2500

|

3000

|

|

Treatment Capacity(m3/h)

|

4/15

|

6/25

|

8/30

|

10-40

|

15-50

|

|

Power(kw)

|

2.2

|

3

|

3

|

5.5

|

|

|

Washing Water Consumption(m3/h)

|

≥6

|

≥8

|

≥12

|

≥16

|

≥18

|

|

Washing Water Pressure(Mpa)

|

≥0.5

|

≥0.5

|

≥0.5

|

≥0.5

|

≥0.6

|

|

Air Pressure(Mpa)

|

0.4-0.6

|

0.4-0.6

|

0.4-0.6

|

0.4-0.6

|

0.5-0.8

|

|

Mud Cake Moisture Content(%)

|

75-80

|

75-80

|

75-80

|

75-80

|

75-80

|

Hot Searches