- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Believe Machinery

-

Dimension(L*W*H):

-

12*1.5*2.5M

-

Voltage:

-

220V/380V

-

Power:

-

1.5kw

-

Weight (KG):

-

1000

-

Control Cabinet:

-

PLC automatic control cabinet

-

Raw material size:

-

less than 10cm

-

Carbonizing rate:

-

99%

-

Capacity:

-

300-1200KG/H

-

Moisture of material:

-

less than 25%

-

Raw material:

-

Wood Branches sawdust rice husk coconut shell

-

Advantage:

-

Continuous Working Environment Friendly

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Carbonization time:

-

Continously Working

-

Color:

-

Customer's Request

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2024

-

Warranty of core components:

-

2years

-

Brand Name:

-

Believe Machinery

-

Dimension(L*W*H):

-

12*1.5*2.5M

-

Voltage:

-

220V/380V

-

Power:

-

1.5kw

-

Weight (KG):

-

1000

-

Control Cabinet:

-

PLC automatic control cabinet

-

Raw material size:

-

less than 10cm

-

Carbonizing rate:

-

99%

-

Capacity:

-

300-1200KG/H

-

Moisture of material:

-

less than 25%

-

Raw material:

-

Wood Branches sawdust rice husk coconut shell

-

Advantage:

-

Continuous Working Environment Friendly

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Carbonization time:

-

Continously Working

-

Color:

-

Customer's Request

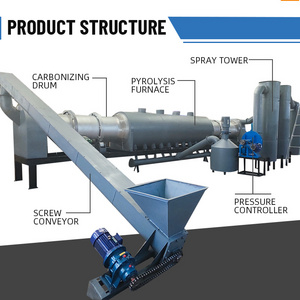

Overview

Production

The roller carbonization furnace is an ideal equipment for carbonizing wood materials (granular with diameter less than 15mm) containing carbon such as wood chips, rice husks, peanut shells, plant stalks, bark, sludge and refuse carbonization under high temperature conditions in the furnace for dry distillation,

oxygen-free carbonization and high carbonization rate.

The carbonization furnace reasonably adopts the technology of recovery, purification and circulation combustion of combustible gas produced in the carbonization process of materials. It not only solves the problem of environmental pollution caused by the smoke produced by the ordinary carbonization furnace in the carbonization project, but also solves the problem of heat energy required by the equipment.

Fully achieved self-supply, improve the continuity of equipment, economy. Make full use of agricultural and forestry residues, turn them into treasures,reduce the contradiction between the supply and demand of China's forestry resources, and make more contributions to the green environment.

Product Advantages

1. Strong sealing and uniform temperature in the furnace.

2. Carbon products have good quality, high carbonization rate and low energy consumption.

3. Equipment safety and environmental protection, easy operation, stable operation, long service life.A large number of new materials, new process selection, patented technology design, precision production, after a large number of practical tests, every detail is the pursuit of perfection, to ensure the quality of each set of equipment.

4.The roller carbonization furnace adopts continuous production mode, which can achieve 24-hour uninterrupted production, greatly improving the production capacity and efficiency of the equipment.

5.The carbonization technology adopted by the equipment, the flue gas generated in the carbonization process can be discharged after purification treatment, and the environment is pollution-free. At the same time, the energy consumption of the equipment is low during operation, which meets the requirements of energy conservation and emission reduction policies.

6.The automatic control system is simple and convenient to operate, and the skill requirements of the operator are not high,which reduces the labor cost of the enterprise

.

Product details

Product Raw Material

This machine can carbonize different biochar materials into charcoal, such as sawdust, wood chips, rice husk, coconut shell etc. Finished charcoal powder can be sold in the market directly, or deep processing into bbq charoal, shisha charcoal, etc.

Technical Parameters

These are the main technical parameters of the product, if you do not know how to choose, you can tell us the raw materials you want to process. We will help you choose the best product for you.

|

Model

|

BDTHL-I

|

BDTHL-II

|

BDTHL-III

|

|

Pipe diameter(mm)

|

100*10000

|

120*10000

|

1500*10000

|

|

Equipment capacity(kg/h)

|

300-400

|

800-1000

|

1200-1500

|

|

Liquefied gas burner(PCS)

|

6

|

6

|

6

|

|

Main burner(PCS)

|

1

|

1

|

1

|

|

Auxiliary burner(PCS)

|

1

|

1

|

1

|

|

Fan(kw)

|

7.5

|

11

|

15

|

|

Distribution fan(kw)

|

3

|

3

|

3

|

|

Main engine of carbonizer(kw)

|

4

|

5.5

|

7.5

|

|

Screw feeder(kw)

|

4

|

4

|

4

|

|

Cooling carbon extractor(kw)

|

3

|

3

|

3

|

About us

Henan Believe Machinery Manufacturing Co., LTD., located in Gongyi City, Henan Province, Da Huang Ye Industrial Park, has built more than 10,000 square meters of plants, is a focus on R & D, production and sales of machinery and equipment manufacturers.

The main production of ball press machine, charcoal machine, carbonization furnace and other mechanical equipment. So far, the company's products have passed more than 20 national patents, but also through the ISO, TUV, CE and other quality system certification.

You will not be disappointed if you choose us.

Over the years, we have been engaged in the research, development, and production of charcoal making machine. We have many types carbonization furnace and our technology has been continuously improving. Our aim is to provide our customers with more professional and reliable recycling equipment.

We are factory, we can provide the higher quality machine at lower price, we have stocks, we can deliver quickly.

Packing & Shipping

Our products are standard export packaging, spare parts are packed in wooden cases, large machines are packed in containers, and can also be packed according to customer needs. We have excellent freight forwarders to arrange sea freight for each customer, with competitive prices and safe transportation.

Our Service

Pre-sales service

:

1. Provide comprehensive technical and business advisory services.

2. To provide customers with the most suitable solutions and equipment.

3. Design and manufacture targeted products according to customers' special requirements.

4. Provide detailed technical training for customers. It includes the operation process of the equipment, the main faults and the troubleshooting methods of common faults.

After-sales service:

1. Strictly check each process of the equipment, quality first.

2. Fast and safe delivery.

3. Provide on-site installation services to ensure the normal operation of the equipment.

4. Provide lifelong maintenance services.

You will not be disappointed if you choose us.

FAQ

Hot Searches