- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5600*4600*2150mm

-

Weight (KG):

-

4500 KG

-

Power (kW):

-

12

-

wire:

-

Imported German flexible cable

-

Body structure:

-

Cast steel body with aging tempering treatment.

-

software:

-

Weihong

Quick Details

-

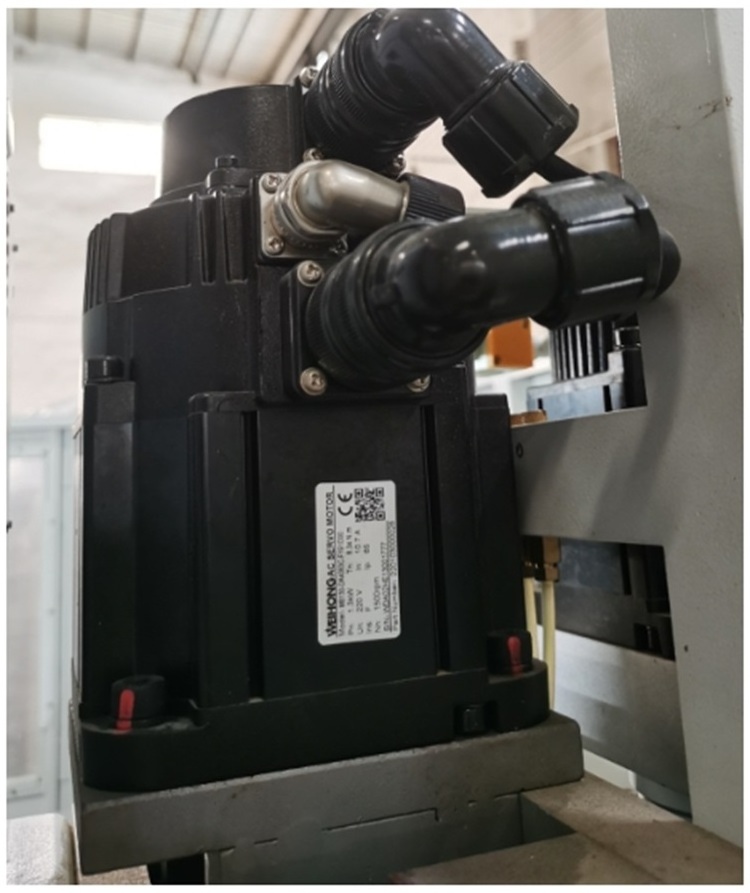

Motor Type:

-

Copper Core

-

Place of Origin:

-

China

-

Brand Name:

-

/

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5600*4600*2150mm

-

Weight (KG):

-

4500 KG

-

Power (kW):

-

12

-

wire:

-

Imported German flexible cable

-

Body structure:

-

Cast steel body with aging tempering treatment.

-

software:

-

Weihong

Products Description

High speed spindle 3.5kw spindle

Top side drilling magazine

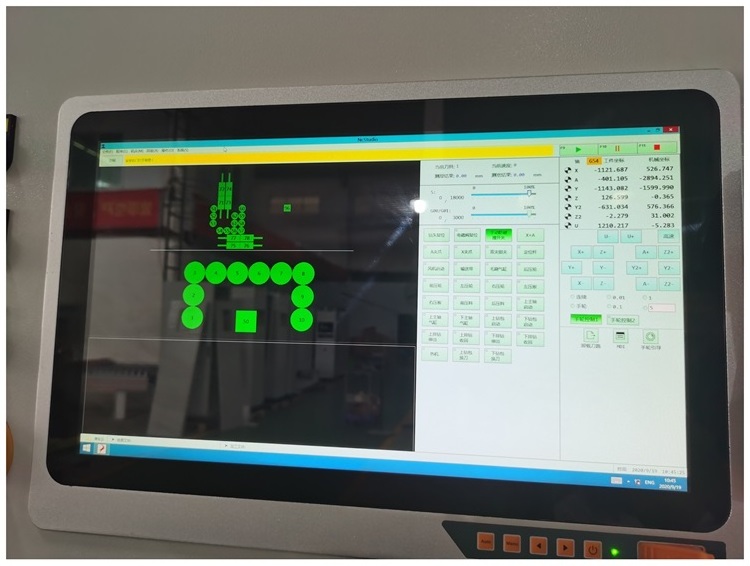

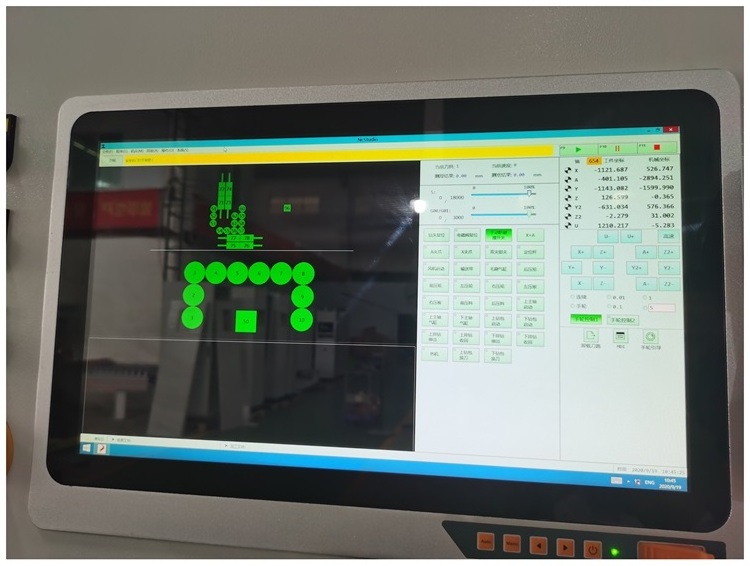

21 inch color screen control display

Using 21-inch color screen to control the display, The single-arm suspension is easy to

operate and saves floor space. The operation is safe and reliable, the interface is simple and friendly, With complete operation

tips and troubleshooting guidelines.

operate and saves floor space. The operation is safe and reliable, the interface is simple and friendly, With complete operation

tips and troubleshooting guidelines.

bottom side drilling magazine and

3.5kw spindle

Schneider electric and Fuling inverter

Double clamping and feeding

The double-clamping mechanism is adopted, and

the board feeding and positioning are automatically controlled according to the computer drilling program to improve the drilling

accuracy.Effectively prevent the edge banding tape from being scratched.

the board feeding and positioning are automatically controlled according to the computer drilling program to improve the drilling

accuracy.Effectively prevent the edge banding tape from being scratched.

Automatic oil injection system

Cylinder-type oil injection system, all rails

use independent cylinders to supply oil, ensuring that all rails are evenly oiled every time.

use independent cylinders to supply oil, ensuring that all rails are evenly oiled every time.

Specifications

|

Control System

|

|

Weihong computer Control System with scream

|

|

|

Speed Reducer

|

|

Helical gear reducer 2M rack

|

|

|

Guide rail

|

|

Tai Wan∕German25mm

|

|

|

Drilled group

|

|

KMS

|

|

|

screw

|

|

Tai Wan&Germany

|

|

|

wire

|

|

Imported German flexible cable

|

|

|

Body structure

|

|

Cast steel body with aging tempering treatment.

|

|

|

software

|

|

Weihong

|

|

|

Work table

|

|

Vacuum worktable

|

|

|

Machine speed

|

Maximum movement speed of hand grip

|

80m/min

|

|

|

|

Maximum moving velocity of Y-axis

|

75m/min

|

|

|

|

Z axis maximum moving speed

|

30m/min

|

|

|

Tool number

|

|

Vertical 12 horizontal 4 * 2

|

|

|

Total power

|

|

12KW

|

|

ABOUT US

ADVANTAGE

EXHIBITION

PACKAGING&TRANSPORTATION

FAQ

Q1. Are your trading company or factory?

A1. We are factory, we have professional R&D team. Our factory located in Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are computer beam saw, edge banding machine, cnc drilling machine, cnc router machine etc.widely used for

panel furniture production.

Q3. What is the payment term?

A3. T/T 30% in advance and balance before shipment, LC or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is 15-30 days, other voltage is 30-45 days.

Q5. What is the guarantee?

A5. 12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine,

you will get spare part for free. Out of 12 months, you will get spare parts at cost price.You will also get technical support and

service all the lifetime.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes ,you will get experienced pre-sales engineer to support, not only including machine and auxiliary selection but also

electrical ,air, machine layout in factory ,etc.

Q7. What is the after sales services?

A7. you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and

consultation, technical support and service by online tools. We can also send our engineer to your factory, but need you take

charge of all travelling cost and labour cost.

A1. We are factory, we have professional R&D team. Our factory located in Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are computer beam saw, edge banding machine, cnc drilling machine, cnc router machine etc.widely used for

panel furniture production.

Q3. What is the payment term?

A3. T/T 30% in advance and balance before shipment, LC or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is 15-30 days, other voltage is 30-45 days.

Q5. What is the guarantee?

A5. 12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine,

you will get spare part for free. Out of 12 months, you will get spare parts at cost price.You will also get technical support and

service all the lifetime.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes ,you will get experienced pre-sales engineer to support, not only including machine and auxiliary selection but also

electrical ,air, machine layout in factory ,etc.

Q7. What is the after sales services?

A7. you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and

consultation, technical support and service by online tools. We can also send our engineer to your factory, but need you take

charge of all travelling cost and labour cost.

Hot Searches