- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.6mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

XHH

-

Voltage:

-

380V/50HZ/3PH

-

Dimension(L*W*H):

-

8000*1500*1600mm

-

Weight:

-

kg

-

Feeding width:

-

840mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Forming Steps:

-

12steps

-

Hydraulic Power:

-

3.7KW

-

Material:

-

Metal Plate

-

Material Thickness:

-

0.3-0.6mm

-

Control system:

-

PLC(imported Brand)

-

Color:

-

Client's Request

-

Cutting blade material:

-

Cr12 Mould Steel

-

Raw material:

-

PPGI

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.3-0.6mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

XHH

-

Voltage:

-

380V/50HZ/3PH

-

Dimension(L*W*H):

-

8000*1500*1600mm

-

Weight:

-

kg

-

Feeding width:

-

840mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Forming Steps:

-

12steps

-

Hydraulic Power:

-

3.7KW

-

Material:

-

Metal Plate

-

Material Thickness:

-

0.3-0.6mm

-

Control system:

-

PLC(imported Brand)

-

Color:

-

Client's Request

-

Cutting blade material:

-

Cr12 Mould Steel

-

Raw material:

-

PPGI

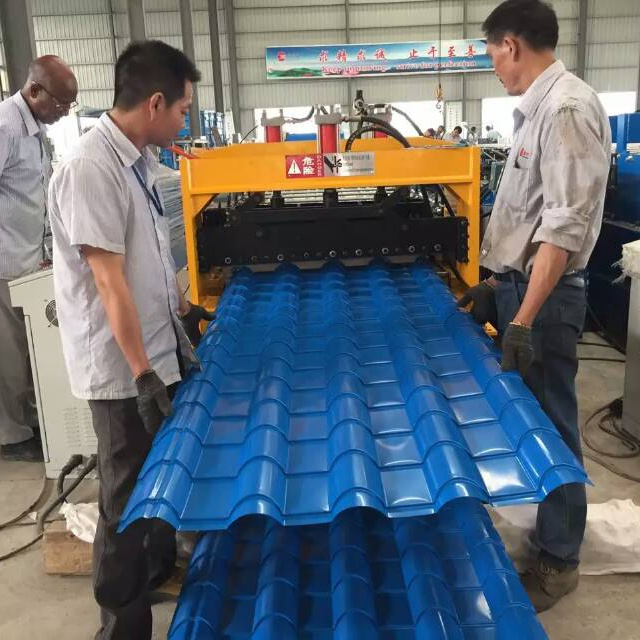

Focus on roll forming machine for more than

19

years

1. Factory Lifetime Service

:offer technical support for the entire life of our machines.

2. Customized Profile :can design the profile according to customer request.

3. ONE-YEAR Guarantee Period :we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

4. Overseas Services Optional :we can send our technicians to install and train the workers in the clients' factories with extra cost.

2. Customized Profile :can design the profile according to customer request.

3. ONE-YEAR Guarantee Period :we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

4. Overseas Services Optional :we can send our technicians to install and train the workers in the clients' factories with extra cost.

Products Description

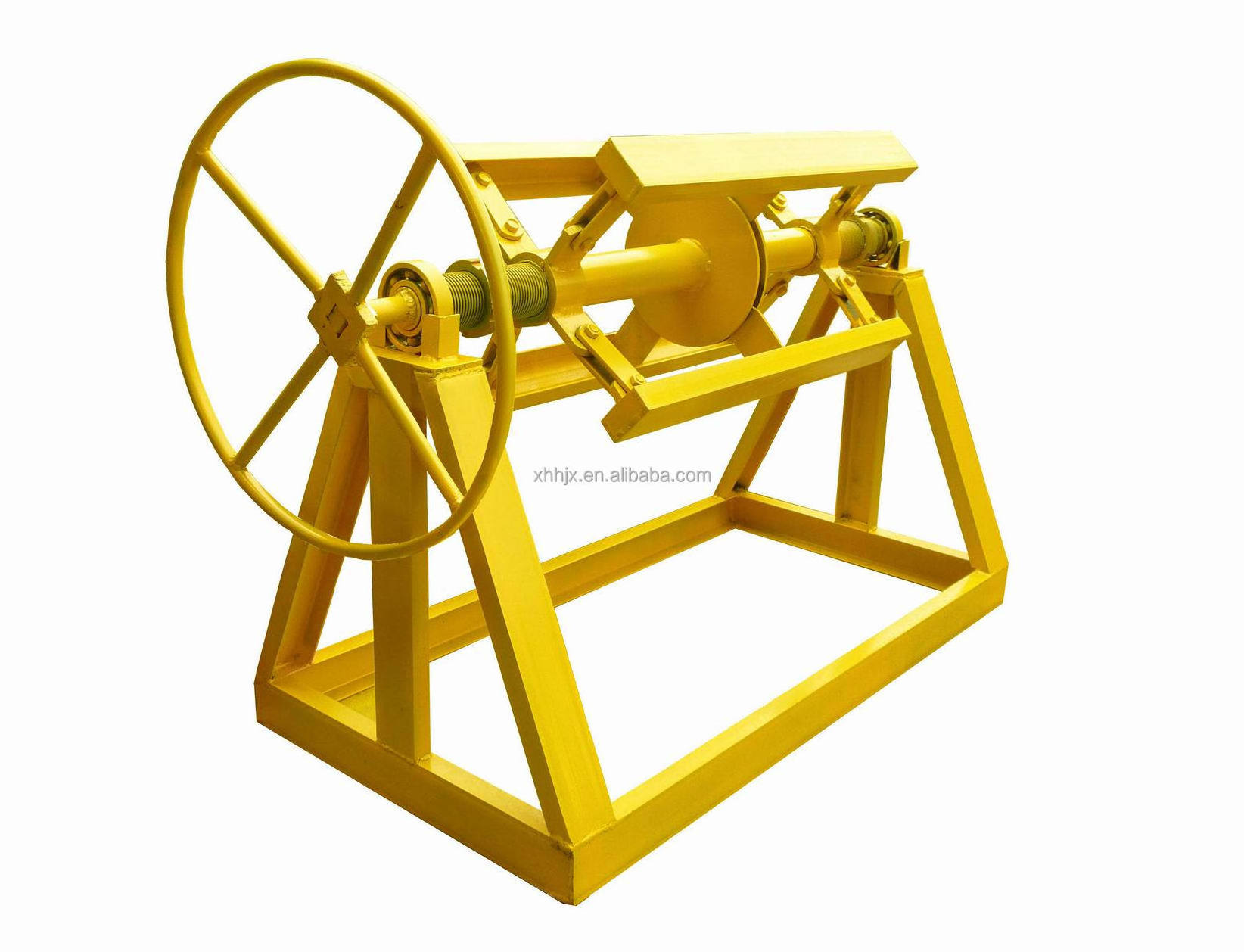

Decoiler

(1) MaxWidth:1250mm

(2) Inner Diameter: 450mm

(3) out diameter:1500mm

(4) max. loading capacity:5Tons

(2) Inner Diameter: 450mm

(3) out diameter:1500mm

(4) max. loading capacity:5Tons

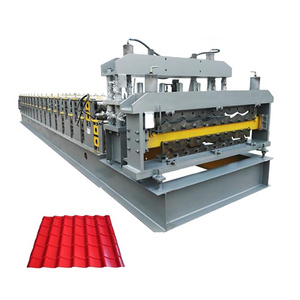

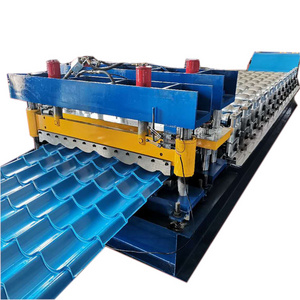

Roll Former

(1) Material Thickness:0.3mm-0.8mm PPGI and Gl

(2) No.of Roller Stations:14 to 18steps

(3) Materal for Rollers: high grade 45#steel polished and plated hard chrome

(4) Material for Shaft:40Cr

(2) No.of Roller Stations:14 to 18steps

(3) Materal for Rollers: high grade 45#steel polished and plated hard chrome

(4) Material for Shaft:40Cr

Cut-Off Device

(1) Material for Cut-off Modular:Crl2mov after treatment

(2) Hardness for Heat Ttreatment:HRC60-62°

(3) Cut-off Type:Hydraulic Cut-off(4)Motor for Hydraulic Stand:2.2KW

(2) Hardness for Heat Ttreatment:HRC60-62°

(3) Cut-off Type:Hydraulic Cut-off(4)Motor for Hydraulic Stand:2.2KW

PLC Control Box

(1) Type:PLC Frequency Contorol Systemwith touch screen

(2) PLC Brand:Schneider

(2) PLC Brand:Schneider

Main Accessories:

(1).Main Forming Machines;

(2).5 Tons Manual Uncoiler;

(3).Hydraulic System;

(4).PLC Computer Controlling System With Touching Screen (Brand: Schneider for PLC, touching screen, cencorder and frequency changer)

(5).Hydraulic Forming Cutter;

(6).Tools;

(7).Operation Manual.

(2).5 Tons Manual Uncoiler;

(3).Hydraulic System;

(4).PLC Computer Controlling System With Touching Screen (Brand: Schneider for PLC, touching screen, cencorder and frequency changer)

(5).Hydraulic Forming Cutter;

(6).Tools;

(7).Operation Manual.

|

Model Number

|

YX37-840

|

|

Size

|

8000*1500*1600mm

|

|

Weight

|

6500KGS

|

|

Motor Power

|

5.5KW

|

|

Hydraulic Power

|

3.7KW

|

|

Voltage

|

380V/50HZ/3PH

|

|

Forming Steps

|

12steps

|

|

Processing Speed

|

8-12m/min

|

|

Thickness

|

0.3mm~0.6mm

|

|

Feeding Material Width

|

1000mm;

|

|

Effective Width

|

840mm

|

|

Height of Roofing

|

38mm

|

Can not find the machine you need?

Why not customize it!

We have engineers with experience more than 17 years!

The configuration is not unique, we will provide you with customized services.

Product Application

Roofing Sheet Making Machine Overview

Main Products

We are the roll forming machine manufacturer, and we can give you the most favorable price.

Welcome to consult price!

Hot Searches