- Product Details

- {{item.text}}

Quick Details

-

Max.Transformer Capacity(kVA):

-

10 kVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YICHENG

-

Motor Power (kw):

-

10

-

Weight (KG):

-

200

-

Dimension(L*W*H):

-

1400 (L) X1200 (W) X800 (H) mm

-

Product name:

-

Toroid Coil Winding Machine

-

Operating voltage:

-

110V ~ 250V

-

Feeding:

-

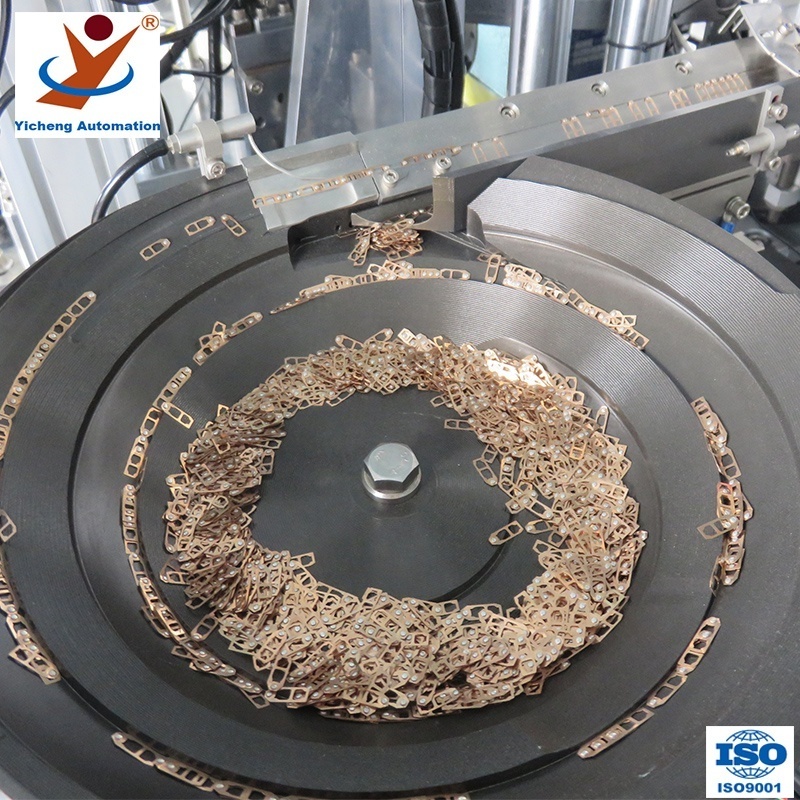

Vibratory bowl feeder

-

Driving pressure:

-

4.5 ~ 6.5kgf/cm2

-

Dimensions:

-

1400 (L) X1200 (W) X800 (H) mm

-

Input air pressure:

-

0.5-0.8MP

-

Packaging:

-

export carton wooden case

-

Production Capacity:

-

15-20pcs/min

-

MOQ:

-

1 Set

Quick Details

-

Max. Load (KG):

-

100 KG

-

Length of Axis (mm):

-

10 mm

-

Center Height (mm):

-

10 mm

-

Max.Transformer Capacity(kVA):

-

10 kVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YICHENG

-

Motor Power (kw):

-

10

-

Weight (KG):

-

200

-

Dimension(L*W*H):

-

1400 (L) X1200 (W) X800 (H) mm

-

Product name:

-

Toroid Coil Winding Machine

-

Operating voltage:

-

110V ~ 250V

-

Feeding:

-

Vibratory bowl feeder

-

Driving pressure:

-

4.5 ~ 6.5kgf/cm2

-

Dimensions:

-

1400 (L) X1200 (W) X800 (H) mm

-

Input air pressure:

-

0.5-0.8MP

-

Packaging:

-

export carton wooden case

-

Production Capacity:

-

15-20pcs/min

-

MOQ:

-

1 Set

Toroid Coil Winding Machine

Function-Toroid Coil Winding Machine:

PLC control system, automatically complete material feeding and assembling; such as wall switch bottom cover, the positive and negative terminal, ground terminal, wing panels, spring, spring fittings, buttons, terminal screws and other parts.

Application-Toroid Coil Winding Machine:

Apply to electrical switches

production areas to achieve automated assembly of wall switch.

Technical parameters-Toroid Coil Winding Machine:

| Production capacity: | 20 ~ 25pcs / min |

| Driving pressure: | 4.5 ~ 6.5kgf / cm2 |

| Operating voltage: | 110V ~ 250V |

| Feeding mode: | vibratory bowl feeder |

| Dimensions: | 1400 (L) X1600 (W) X1600 (H) (mm) |

| Weight: | about 400kg |

Machine Structure-Toroid Coil Winding Machine:

1 Electronic control: Taiwan Weinview touch screen, PLC control;

2 Gas into components: AIRTAC brand cylinder drive, Panasonic or Keyence optical fiber sensor;

3 Two to four vibrator automatic feeding rubber core, terminal, vibration plate painting, baking rack side pass;

4 Structure sliding part choose D2 high speed steel, stable wear, good fixity;

5 One year warranty;

6 Alarm indication;

The machine features-Toroid Coil Winding Machine:

1 This series machine is designed and manufactured specifically for the switching industry

2 Automatic feed terminal, loaded terminal / riveting / one-time processing complete

3. Automatic detecting, automatic start when there is material detected, and auto stop when lack of material

4. Automatic counting, set output

5 using the touch screen, intuitive interface, simple and safe

operation,

6 automatic alarming in case of abnormal shutdown and reporting abnormal information

>>>Click to send your needs for getting solution and quote!<<<