It is widely used to produce the house hold use bottle, like hand wash detergent bottle, pesticide bottle and cosmetics bottle etc.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Faygo Union Machinery

-

Year:

-

2020

-

Voltage:

-

380V or cutomized

-

Dimension(L*W*H):

-

1820*600*1680mm

-

Hollow part volume:

-

500ml

-

Clamping Force (kN):

-

1200N

-

Power (kW):

-

18kw

-

Weight (KG):

-

1500 KG

-

Warranty:

-

1 year

-

Automatic:

-

Semi auto

-

Cavities:

-

2

-

Capacity:

-

800-1000B/H

-

Applicable bottle:

-

PET bottle

-

Suitable volume:

-

200ml-1500ml

-

Suitable bottle:

-

Drink Bottle

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Product name:

-

Automatic Blowing Molding Machine

-

After-sales Service Provided:

-

Engineers

Quick Details

-

Neck Diameter(mm):

-

28 mm

-

Max.Bottle Diameter(mm):

-

100 mm

-

Max.Bottle Height(mm):

-

300 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Faygo Union Machinery

-

Year:

-

2020

-

Voltage:

-

380V or cutomized

-

Dimension(L*W*H):

-

1820*600*1680mm

-

Hollow part volume:

-

500ml

-

Clamping Force (kN):

-

1200N

-

Power (kW):

-

18kw

-

Weight (KG):

-

1500 KG

-

Warranty:

-

1 year

-

Automatic:

-

Semi auto

-

Cavities:

-

2

-

Capacity:

-

800-1000B/H

-

Applicable bottle:

-

PET bottle

-

Suitable volume:

-

200ml-1500ml

-

Suitable bottle:

-

Drink Bottle

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Product name:

-

Automatic Blowing Molding Machine

-

After-sales Service Provided:

-

Engineers

Certifications and Factory Show

Production Introduction

This

semi automatic bottle blow molding machine

is suitable for producing PET plastic containers and bottles from 10-2000ml.

|

Main parameter

|

|

|

||

|

Model

|

FG-8Y1

|

|

||

|

Container

|

Product material

|

PET,PP,PE

|

||

|

|

Volume

|

0.1-2

|

||

|

|

Theoretical output

|

800-1000

|

||

|

|

Preform length

|

15-350

|

||

|

|

Preform inner diameter

|

Φ5-38

|

||

|

Moulding

|

Max.mould plate Dimenstion(L x W)

|

350×380

|

||

|

|

Max.mould thickness

|

180

|

||

|

|

Clamping force

|

45

|

||

|

|

Mould opening stroke

|

16

|

||

|

Machine size and weight

|

Main machine (L x W x H)

|

160×60×161cm

|

||

|

|

Main machine weight

|

500

|

||

|

|

Heater (L x W x H)

|

187×63×145cm

|

||

|

|

Heater weight

|

250

|

||

|

|

Power

|

17.5

|

||

Why Choose us

Our Advantages

1.Perfect function with economic investment.. Perfect function with economic investment.

2.Small size and compact construction with no space waste.

3.Easy to operate and maintain, operation by one person.

4.Saving power and uneasy to worn out.

5.Adopting new double crank in lock mold, the cross fixed Providing high pressure blowing system

6.We can provide preforms and various both &cap molds from 3 gallon to 5 gallon bottes to met Customer's requirements.

2.Small size and compact construction with no space waste.

3.Easy to operate and maintain, operation by one person.

4.Saving power and uneasy to worn out.

5.Adopting new double crank in lock mold, the cross fixed Providing high pressure blowing system

6.We can provide preforms and various both &cap molds from 3 gallon to 5 gallon bottes to met Customer's requirements.

What We Can Blow

Faygo Union

can produce various shapes and sizes of plastic bottles and containers

, including but not limited to:

- Round Bottles : We can produce round bottles in various shapes and sizes, such as water bottles, juice bottles, soda bottles, etc.

- Square Bottles : Fully automatic blow molding machines can also produce square or rectangular bottles, which are commonly used for shipping liquid detergents, cleaning agents, soap solutions, etc.

- Oval Bottles: Fully automatic blow molding machines canproduce oval-shaped bottles, which are commonly used for personal care products such as cosmetics, body washes, shampoos, etc. - Irregular-Shaped Bottles: In addition to the above shapes, we can also produce bottles withunique shapes, such as flat bottles, triangular bottles, hexagonal bottles, etc.

In reality, we can produce many different shapes and sizes of bottles, depending on its design and configuration .If you have anyquestions, please contact us.

- Round Bottles : We can produce round bottles in various shapes and sizes, such as water bottles, juice bottles, soda bottles, etc.

- Square Bottles : Fully automatic blow molding machines can also produce square or rectangular bottles, which are commonly used for shipping liquid detergents, cleaning agents, soap solutions, etc.

- Oval Bottles: Fully automatic blow molding machines canproduce oval-shaped bottles, which are commonly used for personal care products such as cosmetics, body washes, shampoos, etc. - Irregular-Shaped Bottles: In addition to the above shapes, we can also produce bottles withunique shapes, such as flat bottles, triangular bottles, hexagonal bottles, etc.

In reality, we can produce many different shapes and sizes of bottles, depending on its design and configuration .If you have anyquestions, please contact us.

Details

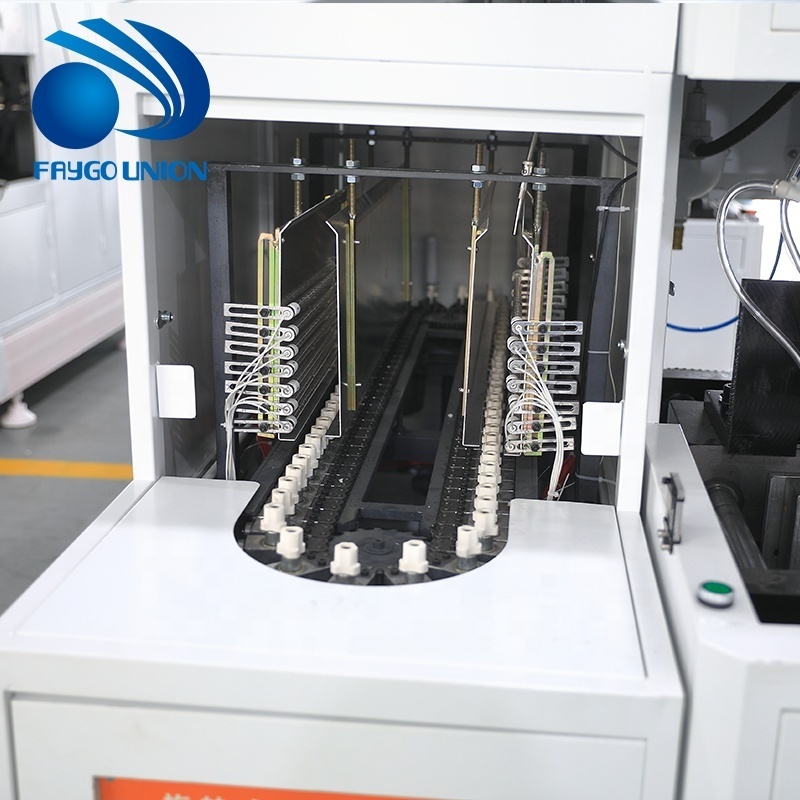

Preform Loading System

Our semi-automatic blow molding machine can hold up to 200 preforms at once. The preforms are loaded into the system manually or automatically, depending on the model. Once loaded, the system transports the preforms to the heating area.

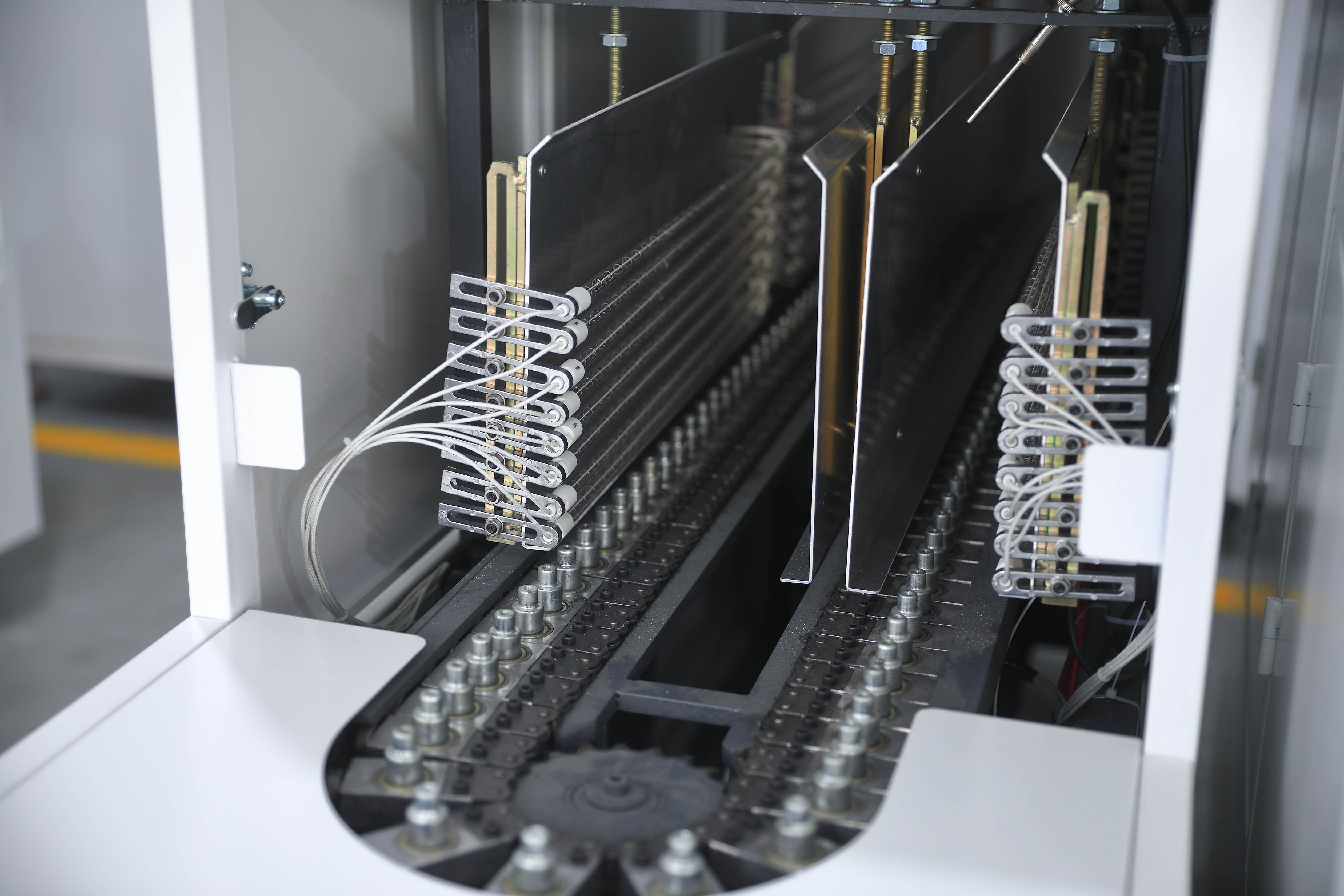

Heating and Stretching System

The heating and stretching system of our machine uses infrared heating lamps to heat the preforms to the desired temperature. Then, a stretching rod stretches the preforms to the correct length and diameter.

Blowing System

The blowing system of our machine uses a high-pressure air jet to blow the preforms into the desired bottle shape. The molds can be quickly and easily changed to produce different bottle shapes and sizes.

Cooling and Ejecting System

After the bottle is blown into the desired shape, it is cooled using a cooling system. The bottle is then ejected from the machine automatically.

User Interface

Our semi-automatic blow molding machine features a user-friendly interface that makes operation and maintenance simple and easy. The operator can adjust the settings for each part of the machine to meet specific production requirements.

More Products

Our extrusion line is widely used for electricity, such as conduit PET bottle.

We also have Full Automatic Blow Molding Machine. Our FG4 Molding Machine is a completely new generation of linear blowing machine, distinguished by its high speed, low power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and high stability, meanwhile conforms to national beverage sanitary standards. This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for mediu; and large enterprises.

Our factory & office

Faygo Union Machinery Co., Ltd

. is a professional enterprise which integrates designing, manufacturing and offering the

turn-key project to our partners.

For decades, Faygo Union has dedicated herself to the packaging machinery of water, beverage, daily use chemical and edible oil.

We have supplied over 70 countries and regions with the following products: air compressors, PET blowing machine, water

treatment,washing-filling-capping assembly line and barreled drinking water assembly line.

Faygo takes “ making good machine; being good person ” as its principle, and we will this philosophy throughout all aspects of production, innovation and strive to achieve beyond optimize product quality for our customers.

Our Services & Strength

We provide 24hours on line service, all life technical support, cost price spare parts in stock. Warranty is 1year, any quality

problem, we can send free spare parts or change new one.

turn-key project to our partners.

For decades, Faygo Union has dedicated herself to the packaging machinery of water, beverage, daily use chemical and edible oil.

We have supplied over 70 countries and regions with the following products: air compressors, PET blowing machine, water

treatment,washing-filling-capping assembly line and barreled drinking water assembly line.

Faygo takes “ making good machine; being good person ” as its principle, and we will this philosophy throughout all aspects of production, innovation and strive to achieve beyond optimize product quality for our customers.

Our Services & Strength

We provide 24hours on line service, all life technical support, cost price spare parts in stock. Warranty is 1year, any quality

problem, we can send free spare parts or change new one.

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2011,sell to North America(30.00%),South America(20.00%),Domestic

Market(17.00%),Africa(8.00%),Mid East(6.00%),Eastern Europe(5.00%),South Asia(5.00%),Central America(4.00%),Western

Europe(2.00%),Southeast Asia(00.00%),Northern Europe(00.00%),Southern Europe(00.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.what can you buy from us?

Bottle blowing machine, extruder machine

4. why should you buy from us not from other suppliers?

In the pet blow moulding industry,Yuda is the main provider of high quality high pressure air compressors. Having been supplying high pressure compressors to the pet industry for a number of years.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,Pay

We are based in Jiangsu, China, start from 2011,sell to North America(30.00%),South America(20.00%),Domestic

Market(17.00%),Africa(8.00%),Mid East(6.00%),Eastern Europe(5.00%),South Asia(5.00%),Central America(4.00%),Western

Europe(2.00%),Southeast Asia(00.00%),Northern Europe(00.00%),Southern Europe(00.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.what can you buy from us?

Bottle blowing machine, extruder machine

4. why should you buy from us not from other suppliers?

In the pet blow moulding industry,Yuda is the main provider of high quality high pressure air compressors. Having been supplying high pressure compressors to the pet industry for a number of years.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,Pay

Hot Searches